Events

Buy Semi-Finished Nuts for Perfect Projects

News 2025-06-13 321

In the field of construction and engineering, the suitable materials can really make a huge difference. Hey, as someone who's been doing this for a while, I've seen just how valuable these pre-finished nuts are for getting accuracy and keeping things efficient. Alright, in this piece, I'm gonna share my take on why these pre-finished nuts are so awesome and how they changed the game for my projects.

Number one: they're all about customization and giving you the precision you need.

And number two: it's all about saving time and, trust me, it adds up to saved money too.

Four on the list is all about variety. Whether I need metric or imperial, they got what I need.

Five is about keeping things protected from scuffs and corrosion.

Number one: they're all about customization and giving you the precision you need.

One of the main reasons I love using semi-finished nuts is their ability to be customized. Thus, lately I required nuts with precisely the required thread size and diameter. Semi-finished nuts provided exactly what we needed, definitely enhancing the quality of that project.

And number two: it's all about saving time and, trust me, it adds up to saved money too.

Time equals money, and semi-finished nuts have demonstrated to be a time and cost-saving solution for my projects. I am not required to wait while they are being processed from raw materials. I simply purchase them pre-assembled and it significantly reduces the time. Rewrote the rules for my team, allowed us to complete projects more swiftly and at a more favorable cost as well.

Number three is the quality. Top-notch stuff like stainless steel or alloy. They just last longer than the ones you'd get otherwise.

Quality really counts. I go for the ones that are made from the quality materials, stainless or metal alloy, 'cause These materials be durable better. I've observed These materials've been making our tasks enhanced strength and longer-lasting.

Four on the list is all about variety. Whether I need metric or imperial, they got what I need.

Having all these various dimensions and systems available is a benefit. No matter what size I need for metric or standard threading, These materials've provide support. And that's been key in handling everything from building furniture to repairing heavy equipment.

Five is about keeping things protected from scuffs and corrosion.

In the past, I experienced problems with nuts becoming dented or corroded during the transfer to the construction site. With these unfinished items, There's been a stark difference. They're resisted wear better due to the protective coverings, and it reduces on the maintenance and replacement I usually need to carry out.

Related articles

- IPX 4 vs 5: A Dive into Waterproof Ratings

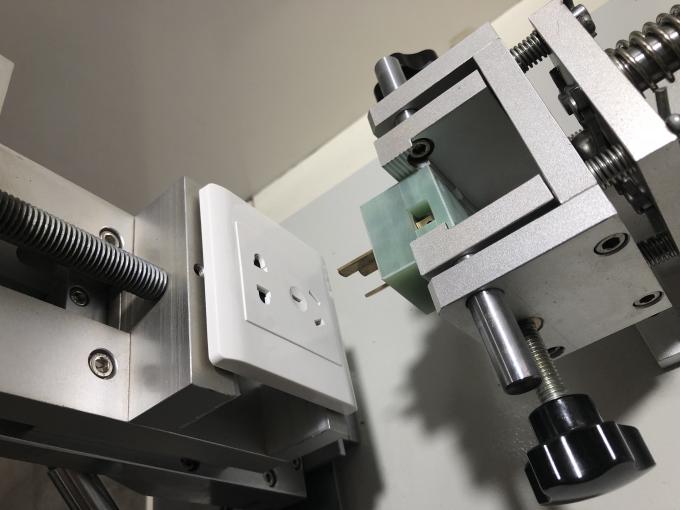

- Crafting Security: Insights from Fabric Penetration Testers

- Unlocking the Testing Equipment Calibration Price: A Comprehensive Guide

- Revolutionizing Spraying: Universal Spray Nozzle Plans

- Affordable High-Quality Foam Rebound Test Products

- Types of Blister Packaging: A Comprehensive Guide

- Call for Mastery in Flyer Plate Test High Strain Rate

- Visit the World of Surgical Cut Down Set Instruments