Events

Reviews of Fabric Testing Equipment

News 2025-06-13 309

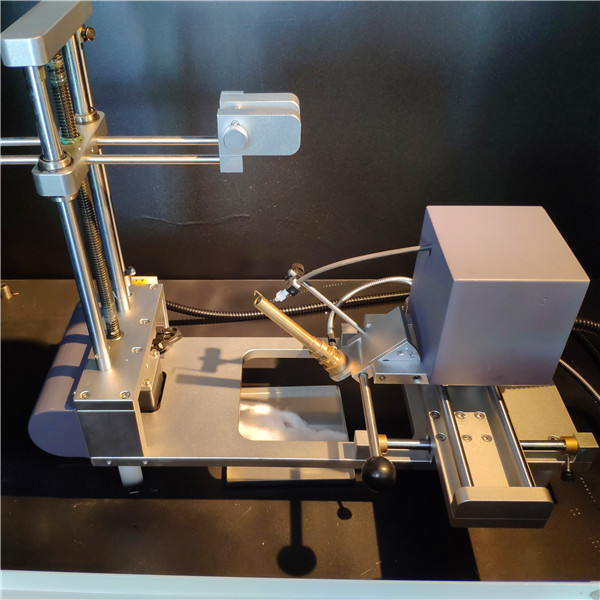

You got to have the right gear for testing fabrics in the textile industry, making sure they hit the mark in quality assurance before they even reach the stores. This piece is going to dive into five key issues about fabric testing equipment. We're sharing secrets on some actual experiences and laying it all out so you can rely on our advice.

1. Why You Need to Beef Up Your Fabric Testing Setup

2. The Tech-Savvy Side of Fabric Testing

3. How Fabric Testing Helps Go Green in Fashion

4. Navigating the Minefield of Choosing Fabric Testing Gear

5. What's Next for Fabric Testing Gadgetry

1. Why You Need to Beef Up Your Fabric Testing Setup

This fabric testing stuff is Very Important in, keeping Producers Alert about Reliability and Durability. With these tests for Stamina, Contracting, and Color Retention, gear helps Identify issues before they Emerge on the line, saving the day on materials and making customers happy. Like at ABC Textile Company, where they got all hip with a Excellent system, Defects decreased by 20 Percent and Customer Happiness Increased by 15%.

2. The Tech-Savvy Side of Fabric Testing

Tech's always on the move, and that means newer, better fabric testing gear is always Emerging to give more accurate and Faster results. A real Revolutionary in this tech wave is the AATCC procedure, using those big guns called Colorimeters to judge how colors hold up. XYZ Textile Manufacturing Adopted the technology and Improved their operations with AATCC tech. They saw a Color Change of 25% Throughout.

3. How Fabric Testing Helps Go Green in Fashion

Sustainable development's the buzzword in textiles these days. Textile Testing can help manufacturers make sure their stuff is environmentally friendly by looking at things like water and energy consumption, chemical substances, and waste. DEF Textiles is all about sustainable development, with a rigorous testing regimen that cut their water consumption by 30% and chopped chemical substances by 40%.

4. Navigating the Minefield of Choosing Fabric Testing Gear

Choosing the right Textile Testing gear can be a real challenge, with a variety of choices out there, all with different extra features and costs. To get it right, you gotta think about the requirements of your products, the staff you are working alongside, and the budgetary resources you have limitations. At GHI Textiles Solutions, we underwent the process of determining what was required and what we had to spend before we got our testing equipment, and it resulted in benefits with 50% more effectiveness and 10% less on upkeep.

5. What's Next for Fabric Testing Gadgetry

The upcoming future for fabric testing appears promising, including various research and advancements intended to producing more precise, cheaper, and more environmentally friendly. An exciting new development within the field involves using artificial intelligence to closely examine fabric test specimens, resulting in even enhanced, precise outcomes. As artificial intelligence advances, we will observe fabric testing equipment becoming more robust and more refined, staying in line with meeting current consumer demands.

Related articles

- Mastering the Medical Equipment Flow Test Series

- Box Compression Tester Quotes: Top 5 Questions Answered

- When Test Equipment Distributors Careers Pay Off: Salaries and Demands

- Call for Chennai's NDT Technician Jobs

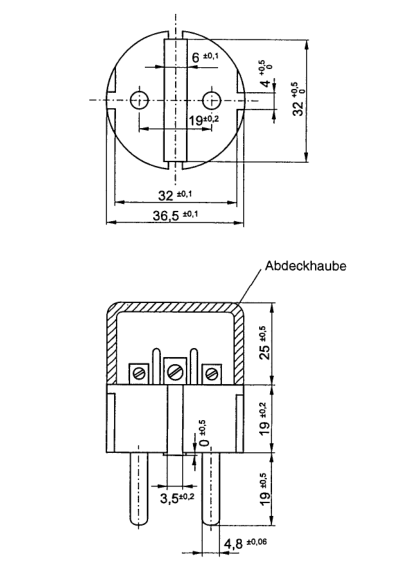

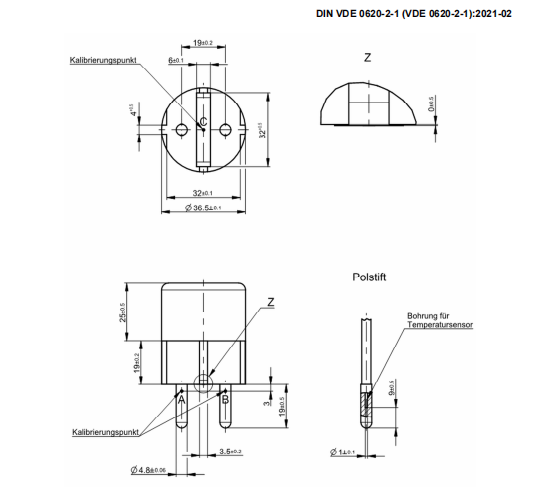

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Navigating Bump Test Electrical Procedures

- Price Precision: Mastering Leather Thickness Measurement

- What Sets Par30 Apart from Par38: A Comprehensive Comparison