Events

Mastering Rubber Testing: What You Need to Know

News 2025-08-17 275

You work in the rubber industry, right? You aware how important good rubber testing equipment is? Rubber testing is a big deal, with a lot of stuff to consider to get it right. So, let's dive into five biggies in rubber testing equipment and see how they can help your business out.

Number one, we've got tensile testing gear.

Number two, compression set testing.

Number three, hardness testing gear.

Number four, temperature resistance testing.

And finally, number five, wear testing gear.

Number one, we've got tensile testing gear.

A really common test on rubber is the tensile strength test. It's all about the extent of elongation the material withstands before it breaks.

You need equipment like the testing equipment to make sure your rubber materials is up to snuff. For instance, we had a client who used our gear to beef up the tires' strength, and it worked great—they got more longevity and happier clients.

Number two, compression set testing.

Compression deflection testing is key to figuring out how rubber elasticity is. It's about how much it compresses under stress and then recovers its shape.

Gear like the compression testing machine is great for doing this kind of test. We had a client who used our compression deflection gear and they told us it allowed them to reduce on quality issues and make their rubber gaskets have a longer lifespan.

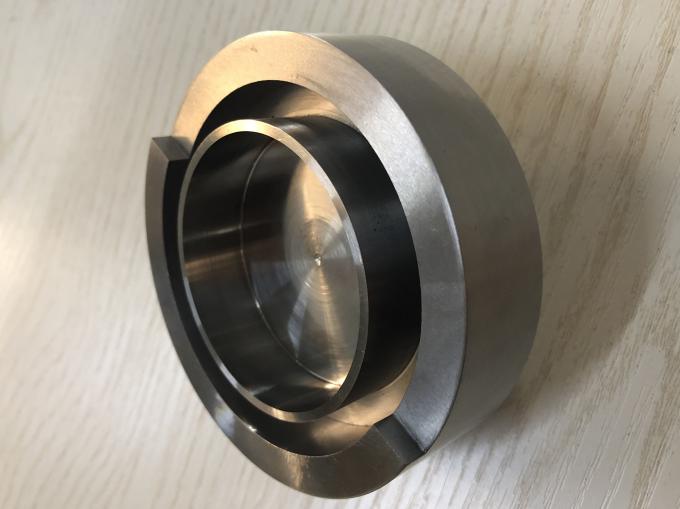

Number three, hardness testing gear.

Sturdiness testing is super also crucial. It's about the rubber's resistance capacity before it starts develops dents or damaged.

Instruments similar to the Shore durometer are often used for this kind of testing. We received a positive feedback for our tensile strength testing equipment on our site. They said it's accurate and easy to use, which facilitated their quick repair of their rubber materials.

Number four, temperature resistance testing.

Testing for resistance to extreme temperatures is an essential requirement to make sure rubber keeps its stuff together under really hot or really cold stuff. The TA Instruments model Q200 is perfect for this kind of test. A client told us our temperature resistance testing equipment assisted them in creating a series of rubber items that can handle severe hot and cold conditions, which got them into new markets.

And finally, number five, wear testing gear.

And last but not least, durability testing is all about figuring out how long rubber items are going to last. The Instron model 5980 is made to simulate the wear on rubber as it occurs in the real world. We had a customer who used our durability testing gear and they said it helped them determine the duration their rubber treads would last, so they could improve their maintenance planning and reduce downtime.

Related articles

- E27 Lamp Cap: A Comprehensive Guide

- Unlocking the IEC Test Equipment List 2021: Free PDF Download Guide

- Inside the World of Button Life Testing Machines

- Mastering Building Safety Glazing Impact Test Frames

- Unlocking Kauçuk Pres: 5 Must-Have Demands

- The Essential Guide to Water Heater Testing Equipment Where

- Mastering Texture Measurement: A Practical Guide

- Electric Bike Test: What You Need to Know