Events

Mastering Building Safety Glazing Impact Test Frames

News 2025-07-10 392

Ever since I first got into safety glass testing equipment, I've been deeply intrigued by how precise and detailed everything is to make sure glass installations are solid. These devices aren't just tools. They're like the protectors of safety in construction. Alright, let me take you through my adventure of getting to know and perfecting these extremely critical equipment.

1. Precision Calibration

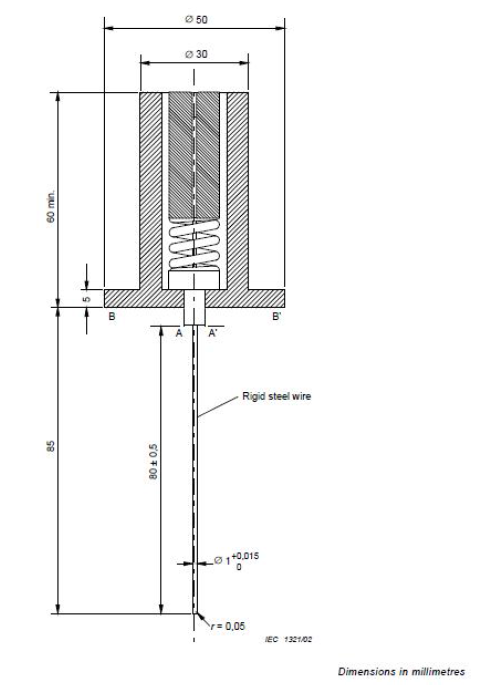

The big deal about working with these safety glass testing equipment is making sure they're extraordinarily precise. These devices are made to act just like real life, where glass can withstand an impact.

The adjustment process is all about performing meticulous adjustments to ensure the force used in the test is perfectly suited for practical scenarios. Like, during my work on a skyscraper, we needed to establish the structure to mimic a falling object impacting it from a particular altitude. It required a blend of the skills of a scientist and an artist, requiring a keen eye for detail and extensive knowledge of physics.

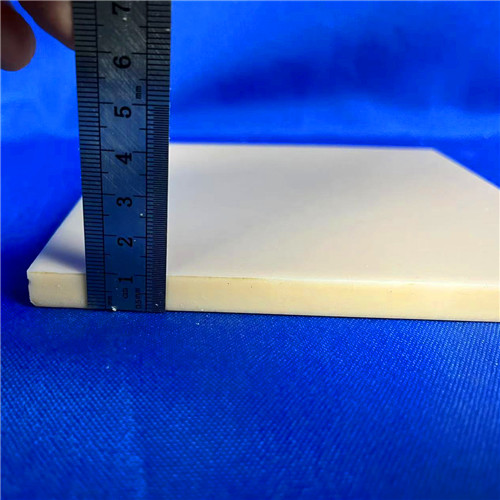

2. Durability Testing

Furthermore, there is something known as durability testing, which is highly significant when working with these structures. It involves more than just dealing with a single impact; it's about making sure it can take lots of hits repeatedly.

I recall an instance where we were required to test the frame against all kinds of simulated attacks, each successive one more challenging than the previous. The frame had to cope not only with the impact, but also the vibrations and strain that result from it. It served as a means to observe whether the frame could withstand and recover.

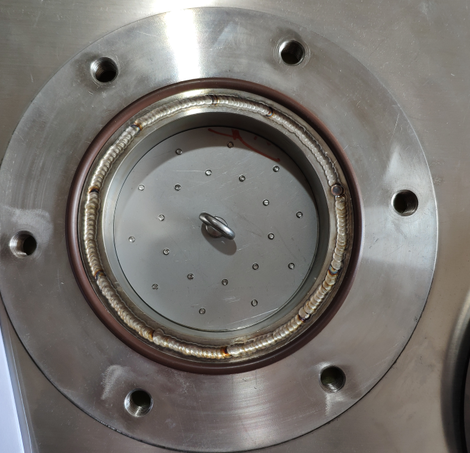

3. Compliance Standards

Every frame I've worked with has to meet extremely stringent trade regulations. Those guidelines make sure the frame and the glass it tests are extraordinarily secure.

Discerning those guidelines is super important for anyone in this profession. Like when I was working on a state initiative, we had to follow the hardest regulations to make sure government-owned structures were extraordinarily secure. It was considerable effort, but it felt satisfying knowing we were ensuring the safety of all.

4. Operator Training

Operating a building safety glass impact testing device isn't for wimps. You need specific training to make sure the experiments are conducted safely and accurately.

I've been fortunate to instruct new individuals how to work with these frames. It's a combination of understanding the technical details and actually performing it. One of the highlighted moments was observing a newcomer conduct a test with absolute confidence and get through it successfully.

5. Maintenance and Upkeep

Keeping these units in excellent condition is super important for how long they endure and how dependable they are. Through time, these units can get covered in dust, have debris stuck on them, and get a bit aged.

Routine maintenance ensures accuracy and helps them endure longer. I've learned how to do regular checks and servicing to keep these units in top condition. It's a job that needs perseverance and paying detail-oriented attention.

If you're really into increasing knowledge about building safety measures glass impact test units, here are some materials I'd recommend checking out:

ISO 61373: This is about glass in buildings, how safe it is, and how it works outside.

Related articles

- How to Find Test Equipment in Lake Mary, FL

- Affordable HDT/VICAT Tester Manufacturer Insights

- Innovations in Leak Test Equipment for Manufacturing When Efficiency Meets Reliability

- Unveiling the Essentials of Rain Testing Machines

- How to Choose the Perfect Rattle Toy Tester

- Mastering the Tensile Strength Test Machine

- Optimizing Your corrugated Packaging Line

- IEC Standard 60529: Navigating Environmental Protection Ratings