Events

Testing Machine Instruments: Unveiling the Secrets of Precision

News 2025-08-17 308

You know, testing devices are a big deal in quality management and progress across a bunch of industries. Back in the day, we had these basic meters. Now, we've got all these fancy testing devices. It's like they've come a long way. So, in this article, I'm gonna explore five main themes about testing devices. I'll be sharing some of my personal experiences and stuff.

First up, we've got the evolution of testing machines.

Next, we've got Calibration, which is super important.

After that, we'll talk about how these machines do their thing in quality control.

Then, we'll jump into all the cool tech advances with testing machines.

And last but not least, we'll look into the future of these machines.

First up, we've got the evolution of testing machines.

When I first started in product quality management, I was blown away by how much these machines have evolved. From those old, manual calipers and micrometers to the super-smart digital systems we're using now, these machines have become way more accurate and efficient. Like, remember those computer-generated displays they came out with in the '80s? They totally changed how we record and monitor data.

Next, we've got Calibration, which is super important.

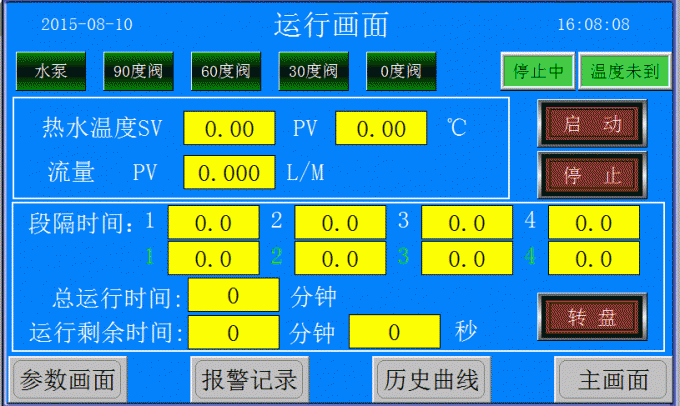

<p Calibration process is a vital element of testing machine instruments. There was this time I was working on a task that needed extremely accurate measurements.

We had to make sure our machine was correctly configured so we could get accurate results. Calibration merely maintains accuracy; it also prolongs the machine's lifespan. Did you know that a report suggests that consistent calibration may extend the testing machine's lifespan by 30%?

After that, we'll talk about how these machines do their thing in quality control.

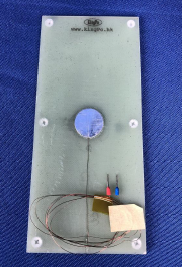

<p testing machines have a crucial role in quality assurance in various industries. From what I've seen, these machines identify issues with products before they are released, which conserves companies time and money.

Take the automotive industry, for instance. These machines check if car parts are up to standards, so they don't have to recall stuff later or handle accidents. ISO International Organization for Standardization (ISO) says using these machines can reduce defects by 50%.

Then, we'll jump into all the cool tech advances with testing machines.

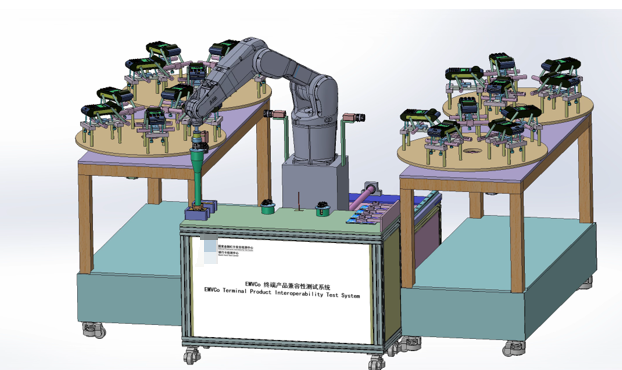

<p The technology at the core of testing equipment has advanced considerably throughout the years. I recall this project where we had to use a machine that could capable of reaching 100,000 per second.

You couldn't even imagine this level of accuracy a few decades ago. Currently, we have these machines that can perform a variety of tests, including fatigue, impact tests, and vibration tests, which greatly assist with creating superior products.

And last but not least, we'll look into the future of these machines.

<p As technology continues to evolve, the future of testing machine instruments looks promising. I believe we will witness additional intelligent, self-operating devices that can address a range of tests and provide immediate feedback.

According through what I read, the industry of testing devices will be at expected through increase more or less 4. 5 percentage points during the period of the year the year of the year the year 2021 until the year the year the year 2026.

Related articles

- Designing an Effective Automated Testing Scheme

- Ensuring Safety: The Electrical Safety Test of Medical Equipment

- Coupon: Defending Against Water Ingress

- Navigating GB9706 Series Safety and Security Regulations

- Unlock the Power of Sale with Surface Insulation Resistance

- When Thermal Abuse Test Chambers Excel

- How VDA Lithium-ion Battery Exporter Shapes the Market

- Tensile Strength Unveiled: A Deep Dive