Events

Venturing into the World of Burn in Chambers

News 2025-07-28 233

Ever think about those mysterious Testing facilities? These gadgets are extremely crucial for testing electronics. In this piece, I'm going to chat about five main themes about Testing facilities, based on my own stuff. Let's explore!

1. What's the Deal with Burn-in Chambers?

2. What Kinds of Burn-in Chambers Are Out There?

3. Operating Burn-in Chambers Isn't Easy

5. Where Are Burn-in Chambers Headed?

1. What's the Deal with Burn-in Chambers?

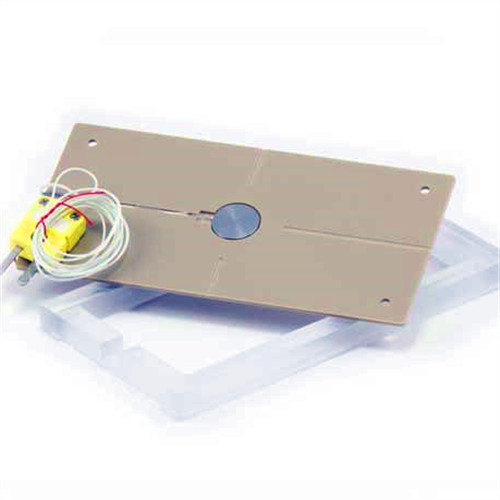

Aging simulators imitate how electronic parts age. They use really extreme temperatures and volts to detect any vulnerabilities before they turn into major issues.

It's a intelligent method to ensure continuous operation. From mysemiconductor testing period, I've learned these aging simulators are critical for quality products.

2. What Kinds of Burn-in Chambers Are Out There?

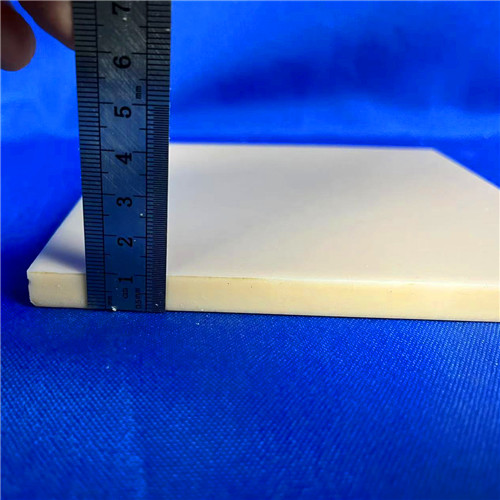

There are various types of burn-in chamber, each with their own unique features. Some common types include air-filled chambers, vacuum chambers, and liquid nitrogen chambers.

I've had the opportunity to work with several of these chambers and can attest to their effectiveness. For example, air-bath ones are good for materials prone to instability in damp or hot environments. Vacuum ones are perfect for things that need a extremely dry atmosphere.

3. Operating Burn-in Chambers Isn't Easy

Operating burn-in chambers isn't easy; you must be very careful with the settings. You got to follow the book, and maintain their cleanliness to get the best out of 'em.

One issue I faced was a sudden increase in the temperature inside a burn-in chamber, which was caused by a failed temperature control unit. By quickly identifying the issue and replacing the controller, I managed to avoid any harm to the components under test.

4. Data Analysis Counts

Looking at the numbers is a big part of testing these burn-in things. Reviewing the data during the test can truly reveal much about how well the components will perform over time.

I've tried various kinds of software for sorting through the data and found it super useful for identifying issues. One case study I can share is how we were able to identify a engineering defect in a new semiconductor by analyzing the burn-in testing results, which ultimately led to an enhanced item.

5. Where Are Burn-in Chambers Headed?

The world of burn-in chambers is constantly evolving with new innovations emerging all the time. I believe that advancements in AI and machine learning will have a major impact in the future of burn-in testing.

With this fancy tech, engineers can prevent issues from occurring, making stuff more reliable. Being in within this field, I can't wait to see the future developments.

Related articles

- Applications Where Dynamometers Shine

- Coupon Deal on Top Foam Rebound Resilience Tester

- Dust Chamber Compliance: A Guide to IEC 60529 Standards

- What to Consider in Electrical Testing Equipment

- Essentials of Battery Charge and Discharge Test Equipment

- The Applications of Testing Equipment

- Hydraulic Pump Power System: Powering the Modern World

- Sale of High-Temperature Heat Resistant Papers