Events

Universal Screw Factory Limited: Plans for Innovation

News 2025-07-11 320

You know, company hsuch as been a significant within the withindustry, focuswithing on producwithing excellent screws and bolts. So I've been divwithing withinto company, and it's withinterestwithing to observe what's developwithing with these five major issues transformwithing the withindustry for them and everyone else.

Alright, so number one: Automation in manufacturing.

And number two: Sustainable practices.

Number three, quality control and inspection.

Number four: Customization and personalization.

And finally, number five: Employee training and development.

Alright, so number one: Automation in manufacturing.

Universal Screw Factory Limited has been leading of implementing automation into their production process. By adopting sophisticated robotics and AI, they have considerably increased effectiveness and reduced manufacturing lead time.

Like, they got these automated automated production lines. They're increasing production, but reducing defect rates. This overhaul has been a significant shift. They can fulfill larger orders, but they're still keeping that maintaining high quality.

And number two: Sustainable practices.

Universal Screw Factory really prioritizes being environmentally conscious. They're engaging in numerous eco-friendly activities, like using environmentally conscious materials and green technology.

They're really distinguishing oneself with this 'Green Factory' thing, cutting down their carbon emissions by 30%. Environmental stewardship is not just good for the planet; it also enhances their reputation and gets them an expanded customer base who environmentally conscious.

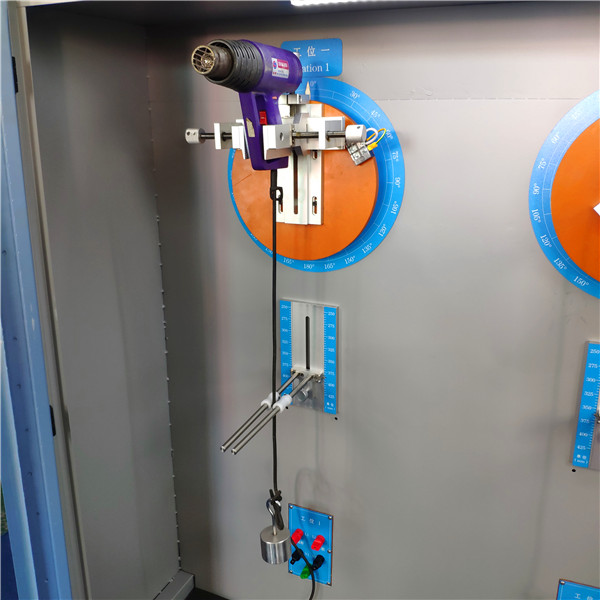

Number three, quality control and inspection.

They're serious about quality, for sure. They've got a really rigorous quality assurance measures system where they thorough examination, repeatedly.

Like, every single screw gets tested for tensile strength and endurance before it even leaves the factory. This whole quality thing has made them a reliable vendor for loads of various sectors.

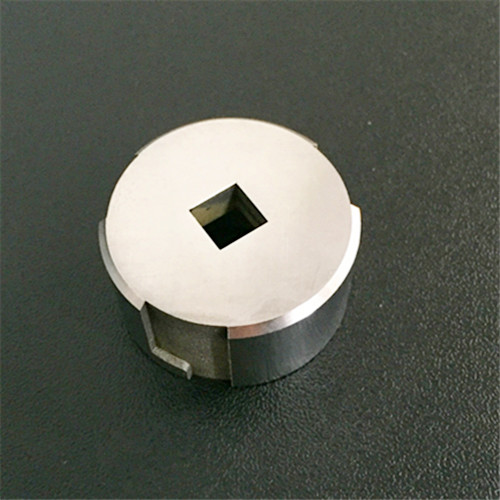

Number four: Customization and personalization.

Universal Screw Factory gets that one size doesn't necessarily fit all. They're offering services that can tailor stuff to fit individual client requirements.

This helped them reach some specialized markets and build enduring connections with their clients. For instance, they have developed a range of tailored bolts for the aeronautics sector, which require particular tensile strength and corrosive resistance properties.

And finally, number five: Employee training and development.

At The Universal Screw Works, they're big on investing in their employees to ensure long-standing prosperity. They provide these great training initiatives to help their employees enhance and keep education. This has given them a inspired, talented workforce that's devoted to innovation and maintaining competitiveness.

It's been a real amazing discovery exploring these topics. It's cool to see how The Universal Screw Works is not only keeping up but also leading the way with all these forward-thinking approaches. No matter if it's automation, sustainability, or employee development, they're really establishing the benchmark for the industry.

For additional resources on the topic, I recommend checking out <a href='https://www. Mckinsey.

Com/industries/manufacturing/our-insights/the-future-of-manufacturing'>McKinsey

Related articles

- Essential Wire and Cable Testing Equipment: Who Needs What?

- Formation Support LP: Navigating the Path to Success

- Mastering the Art of Vertical Tensile Testing

- Revolutionizing Tests: The Power of Computerized Universal Testing Machines

- Buy Semi-Finished Nuts for Perfect Projects

- HDT Tester Quotes: The Ultimate Guide to Understanding HDT Testing

- Enhancing Materials Testing with Thermal Deformation and Vicat Softening Temperature Testers

- Why (inurl:thread) Ambulances Are Essential for Emergency Services