Events

Torque Strength Tester: Your Ultimate Guide to Power and Precision

News 2025-08-19 267

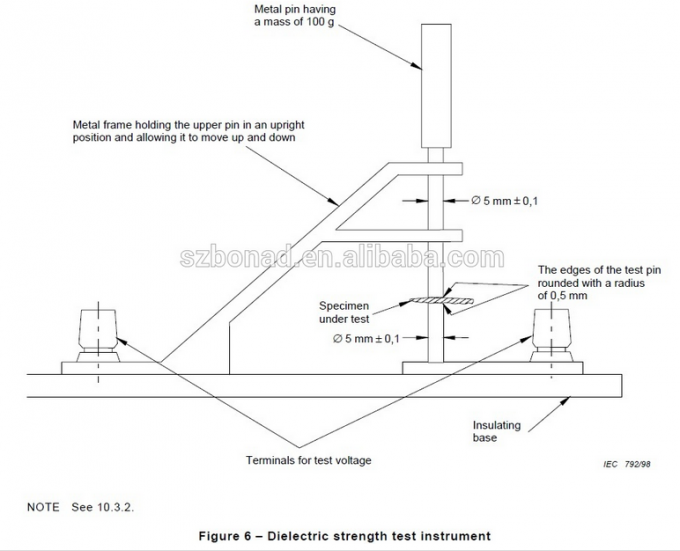

You're in the manufacturing business, and we all know it's all about the proper tools. Now, there's this tool that's very popular—what Also known as a torque strength tester.

1. Accurate Measurement of Torque

2. Compliance with Industry Standards

These little gadgets are an essential to ensure your products have high-quality fasteners. In this article, I'm going to talk about the top five reasons people love torque strength testers and share some personal stories and advice on how they can totally transform the industry for you.

1. Accurate Measurement of Torque

Mainly, these Torque gauges are all about making sure you get just the right degree of force on those screws and bolts. It's vital because if they're over-relaxed or over-tightened, you're gonna have issues.

Remember that once upon a time a bolt broke just because it was too tight? Purchased for myself a fancy torque strength tester, and it's been rockin' since. Now I'm able to obtain that just right, and I'm not worried about those bolts breaking anymore. The tester has been telling us that everything is securely tightened exactly as it needs to be, fabricating our items considerably improved.

2. Compliance with Industry Standards

You've gotta follow the regulations in production, and that's super important. These torque strength testers are like our little enforcers, making sure each fastener follows the rules.

Take the automobile industry, for example. They've got these stringent torque specifications for bolts, and these testers are crucial for keeping up with those. I've been using them to make sure we're on the level, reducing on those headaches and making our customers happier. And you know what? We got 'Top Supplier Award' because of it. Our customers were impressed with our commitment to standards.

3. Efficiency in Production

Using a torque tester can totally optimize your production process and make it more efficient. With the tester giving you the right amount of torque, you'll know those fasteners are correctly applied, which means fewer corrections and repairs.

Since we got those torque testers, we've seen a 20% cut in rework time on the assembly line. Significant victory. Not only does it save time, but it cuts down on expenditures, too. Now, the production team gets to concentrate on more important stuff, and we've got an improved workflow going.

4. Enhanced Safety

Safety is the top priority, especially concerning your products. Torque testers are excellent at identifying loose screws before they lead to any issues or incidents.

There was an instance when a loose bolt resulted in a significant issue with one of our products, nearly causing a safety concern. Ever since, we have utilized torque testers to ensure all our fasteners are securely tight for safety. It's been a revolutionary change for us, really improving our safety history.

5. Customer Satisfaction

Our primary objective in manufacturing is to ensure our customers are satisfied. These torque testers play a significant role in ensuring your products are equipped with reliable, long-lasting fasteners which satisfy our customers.

Our customers have been extremely enthusiastic about our products, stating that it's due to the use of this advanced testing equipment. All this positive feedback has significantly helped us establish our reputation and attract new customers.

Related articles

- Discover the Best Textile Testing Equipment Suppliers

- Mastering Izod Impact Tester Supply Expertise

- Defining Test Equipment: Who Needs What?

- Innovating with High Strength Nuts: A Practical Approach

- What is a Walk-in Temperature Humidity Test Room?

- Discovering Tensile Strength Machine Screws

- Who's Winning the Game with Internal Bond Tester?

- How to Find the Best Tensile Testing Machine Price