Events

Who's Winning the Game with Internal Bond Tester?

News 2025-07-08 274

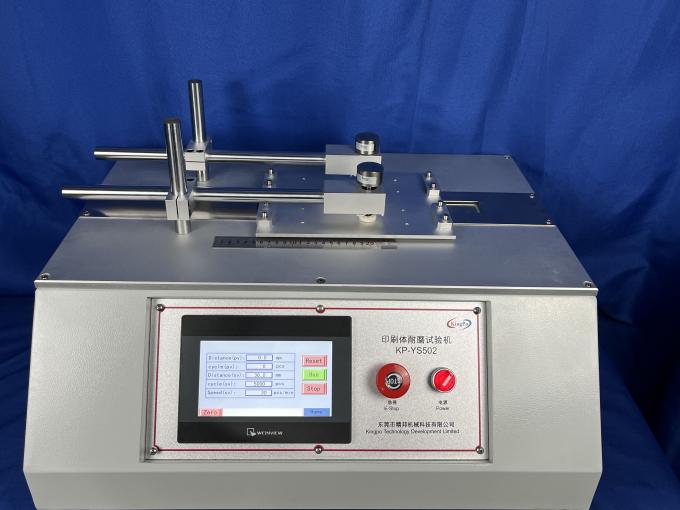

Ever think about how technicians and professionals make sure materials adhere or bond really well? Well, there's this thing called an internal bond tester. It's a important matter in the field of material assessments. No matter if you're in vehicles, aviation vehicles, or construction industry, knowing how materials adhesion is of great significance. In this essay, we'll explore the details of internal bond testers. We will discuss how how they are employed, what makes them appealing, and whose opinions who use them their opinions are.

Number one: the uses of these internal bond tester gadgets.

Number two: why using these bond testers is such a good idea.

Number three: how to pick the right tester for you.

Number four: keeping your tester in tip-top shape.

Number five: what's in store for these bond testers.

Number one: the uses of these internal bond tester gadgets.

They're not just for one thing. Aviation specialists use them to ensure planes don't fall apart. Automotive professionals use them to check if coatings and adhesives stick. They're highly adaptable. For instance, in buildings, they test how well coverings and coatings stick to surfaces, making sure everything lasts a extended duration.

Number two: why using these bond testers is such a good idea.

Why is it advisable to use a bond tester? It gives you reliable outcomes that prevent avoid costly errors and repeating the work.

And by the way? It also helps save time and effort, as it is fast-efficient. As someone in the automotive industry noted: 'This device is transformative. It lets us test lots of different stuff really fast, ensuring our products are of the highest quality. '

Number three: how to pick the right tester for you.

Many testers are available, choosing the appropriate one may seem a bit intimidating. Consider what types of testing you'll need to perform, the level of force you require, and the desired level of accuracy of the results

As someone in the construction industry commented: 'Our choice was based on the tester's ability to accurately test diverse materials. It has been an excellent addition to our tools. '

Number four: keeping your tester in tip-top shape.

You've got to keep your tester in good shape with regular regular upkeep and adjustment. Skipping this could give you poor outcomes and cause issues.

An expert in aviation had this to say: 'We're extremely concerned about regular upkeep and adjustment. It's vital for keeping things safe and guaranteed quality. '

Number five: what's in store for these bond testers.

As technology gets cooler, we'll see even more sophisticated devices. With all of this intelligent devices and IoT, they might soon start giving live information and doing proactive upkeep, increasing their worth. A pro in the field says: 'the destiny of bond testing looks bright. Cutting-edge technology will make it more effective and reliable. '

If you want to learn more about bond strength gauges and application process, explore these materials:

<paragraphResource 1</paragraph<paragraphResource 2</paragraph

Related articles

- Applications and Demands of Medical Signal Sources/Generators

- Coupon Code for Piping Stress Engineer Jobs in Bangalore

- Cheese Machine 2 VST: Mastering the Art of Sound Design

- Innovations in Non-Invasive Blood Pressure Simulators: A New Era in Hypertension Management

- Promo: Unleashing the Power of Vandal-Resistant Step Bolts

- Visit the World of Temperature, Humidity, and Vibration Testing

- The Essential Guide to Impart Test: Where to Start and What to Expect

- Buy the Perfect Wheels and Rims