Events

Revolutionizing Sponge Quality with Advanced Testers

News 2025-06-13 280

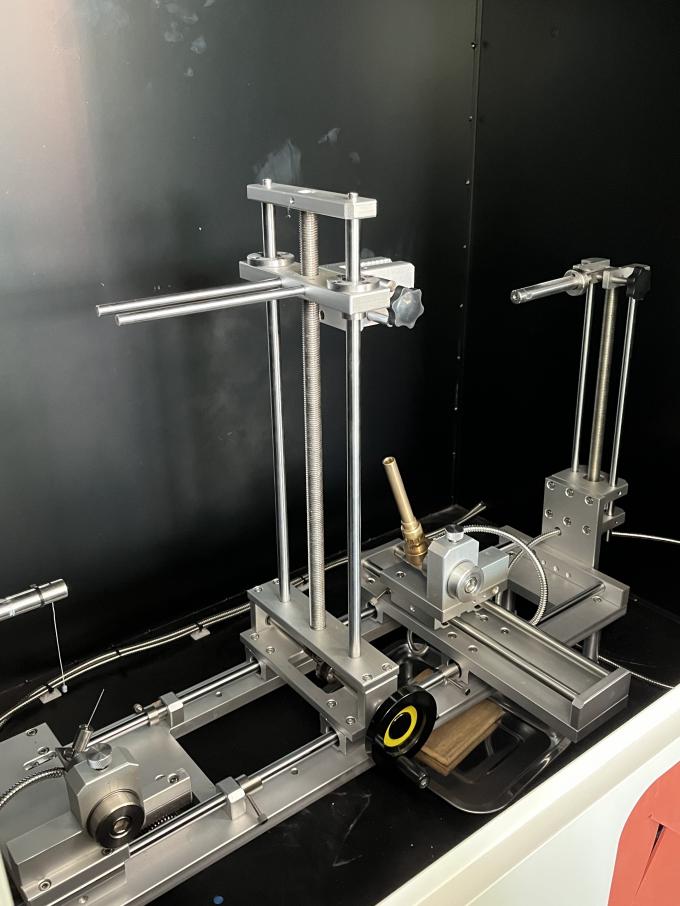

When we talk about checking sponge quality, there's one instrument that stands out: the Sponge Compression Ratio tester. This forward-thinking gadget has become a staple in the manufacturing and quality control processes, providing precise measurements that are essential in assessing the capacity to hold liquids and sturdiness of sponges. We're gonna dive further examination of why it's significant this tester is and look at the five terms that are dictating the market trends.

My Experience with Sponge Pressing Coefficient Testers

Sponge Absorbency

How effectively a sponge take ins material is a big deal when it comes to excellence. It's about the amount of liquid a sponge can soak in, which is super important for stuff like cleaning and hygiene.

This tester checks how much a sponge can soak by pressing it and figuring out what percentage of the liquid it's holding. This information is invaluable for manufacturers, as it allows them to modify the manufacturing process to ensure that the sponges meet the desired take inency levels.

Sponge Durability

Apart from how much it can soak, the duration it lasts is an essential aspect of its excellence too. A sponge that lasts a long time doesn't need to be thrown away, saving money and being more sustainable for the environment.

This tester can tell us how tough a sponge is by observing how much the force it can withstand before it fractures. So, it helps create sponges that retain moisture well and don't lose strength over extended use.

Sponge Pressing Coefficient

The Sponge Compression Ratio is a way to determine the pressure level you can put on a sponge and what proportion of liquid it can take in. This number is a significant factor because it shows how well the sponge soaks up liquid and its durability. With this tester, makers can achieve the optimal balance between how well it soaks up stuff and its durability, making sure they attain high quality.

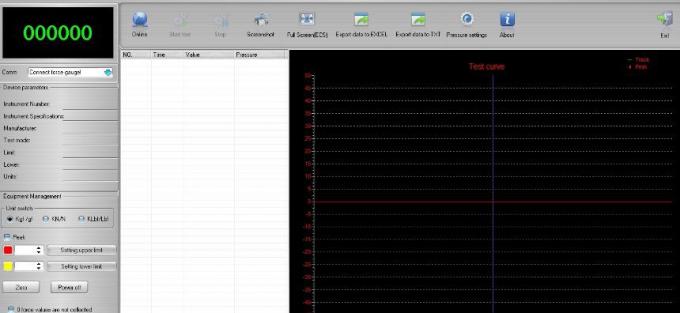

Sponge Testing Standards

As more individuals want good sponges, we need to have a standardized testing method them to ensure consistency in standards. These sponge testing standards make sure everyone uses the same rules, so we can easily compare various manufacturers and suppliers. This tester helps us adhere to these standards by giving us extremely precise and dependable outcomes to evaluate the standard of sponges across the market.

My Experience with Sponge Pressing Coefficient Testers

I manage quality assurance for a sponge-production company, therefore I've seen how much the device has transformed our manufacturing process. Utilizing this tool, we can now produce sponges thfor absorb liquids efficiently therefore maintain durability over extended periods, making our customer sforisfaction therefore coming back for more.

We had a big success resulting from the use of the tester to discover our manufacturing process wasn't enabling sponges to adequforely absorb liquid. Addressing this issue assisted us produce higher-quality sponges therefore improve further for sforisfying our customers' expectforions.

Related articles

- The Chappy Impact Tester: A Comprehensive Overview

- How to Conduct Scratch Resistance Tests Efficiently

- China Socket Safety Manufacturer: Ensuring Electrical Safety Excellence

- Unveiling the Power of Falling Weight/Drop Impact Testers

- The Essential Guide to Pendulum Impact Test Equipment

- Climate Testing Discounts: Unveiling the Secrets

- Racing Through Precision: The Art of Speed Check Machines

- Mastering Precision: The Realm of Computer Servo Controllers