Events

Mastering the Art of Drop Test Steel Ball

News 2025-06-13 314

Hey everyone, let's dive into this interesting topic about drop test steel balls! It's quite a intriguing subject. These balls are not ordinary spheres—they're actually extremely significant for figuring out how strong stuff is when it gets hit. So, there's a range of topics to talk about when it comes to drop test steel balls—let's dive into the top five topics.

Drop Test Steel Ball Standards

Types of Drop Test Steel Balls

Applications in Various Industries

Drop Test Steel Ball Standards

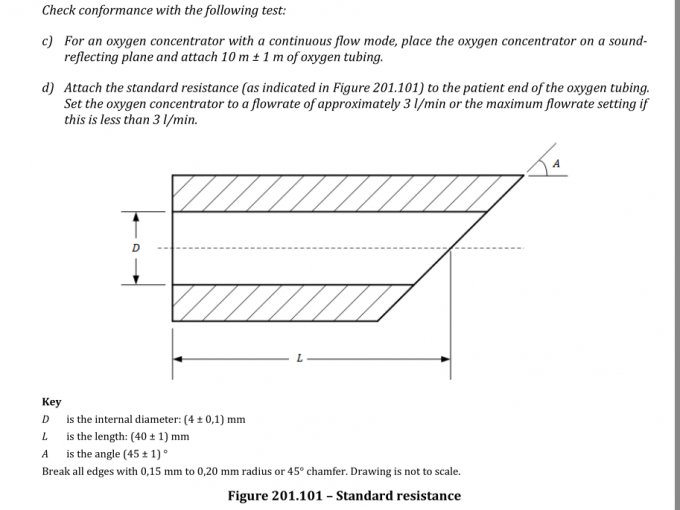

You know, having a good set of standards for these balls is extremely significant. And the established norms are there to ensure reliable test results and we can trust the results.

For instance, the standard ISO 2243 says how big and heavy those required steel ball specifications for impact testing. It's totally necessary to adhere to these standards so ensure accurate results.

Types of Drop Test Steel Balls

Did you know there's more than one kind of drop test steel ball out there? Each type of those steel balls features distinct properties and applications. So, for the Charpy impact test, we usually use those steel balls that are about a centimeter in size and made from this strong, high-carbon steel material.

On the other hand, the Izod impact test gets done with these even smaller steel balls, about three and a half millimeters across, made from softer, lower-carbon steel. Determining which kind of ball is right for your test is extremely important.

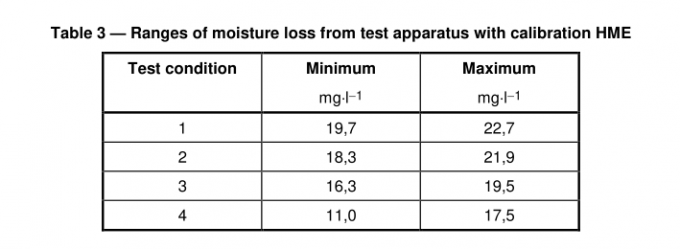

Impact Resistance Testing

Collision resistance testing is an important matter when we're assessing materials. When you drop a steel sphere on a material, we can see how much energy the material can absorb before it shatters.

This info helps us make products that are actually tough and can handle real-world conditions. Also, these tests help us locate the vulnerabilities in materials so we can improve the design and make things better.

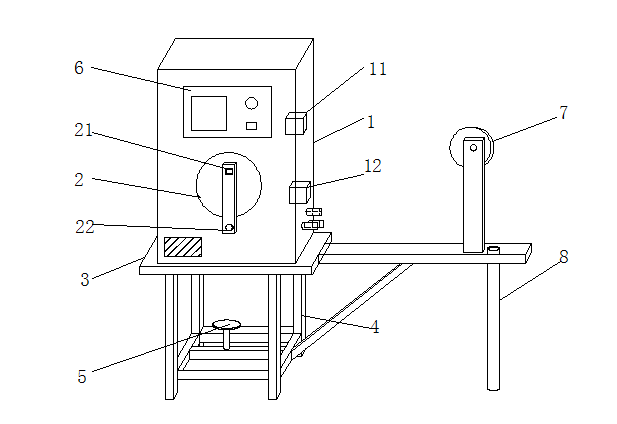

Equipment and Safety

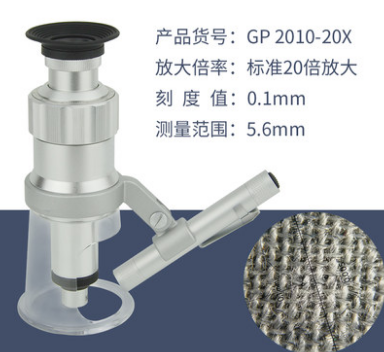

You gotta have the correct equipment and adhere to safety protocols when doing these tests. Ensure the testing equipment is functioning correctly and well-maintained so you get dependable outcomes.

Additionally, safety equipment, such as safety gloves and eye protection, is essential to guard the tester from possible dangers. Always exercise caution by having someone else with you while you're doing the test.

Applications in Various Industries

These metal spheres are extremely helpful in various fields, such as vehicles, aeroplanes, and structures. For example, in automotive applications, these evaluations ensure that automotive components can withstand being impacted.

In the aerospace sector, these assessments verify if aircraft components are sufficiently robust. And in the construction industry, they help make sure the materials maintain their integrity over time.

Related articles

- Innovative Solutions: Fabric Strength Testing Machine Prices

- The Essential Guide to International Cord Sets

- The Importance of Scratch Resistance: What You Need to Know

- What a Leather Contraction Temperature Tester Manufacturer Offers

- Buy and Master Needle Cannula Holders

- Why Other Rehabilitation Testing Equipment Matters

- Ensuring Precision: The Role of Biological Safety Cabinet Calibration Devices

- Advanced Pulse Test Generator: Enhancing Precision in Electronics Testing