Single Station Fixation Pins Plug Socket Tester , Clause 24 Figure 30 IEC Test Equipment

Single Station Fixation Pins Plug Socket Tester , Clause 24 Figure 30 IEC Test Equipment

- Model:

Single Station Fixation Pins Plug Socket Tester , Clause 24 Figure 30 IEC Test Equipment

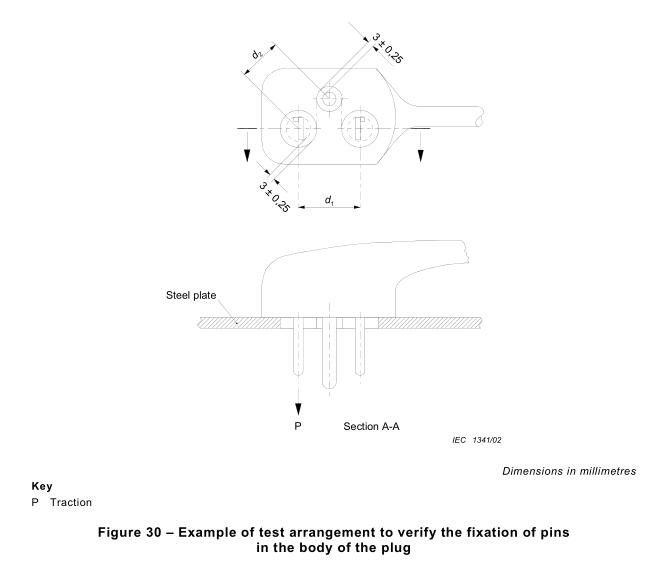

IEC60884 Clause 24 Clause 24.10 Figure 30 Testing Equipment Of Single Station Fixation Pins In The Body Of The Plug Tester

Standard: IEC 60884-1 2013 clause 24.10 and figure 30

Application: This device is use to verify the fixation of pins in the body of the plug

Test sample: Plug pins

Feature: In according with standard requirements, to verify the fixation of pins in the body of the plug

Parameters:

| Number of test station | 1 |

| Weight | 50N*1, 20N*2, 30N*1, 4N*1 |

| Standard socket: each one of Mexican standard for configurations: | C1.1, C1.2, C1.3, C1.4, C1.5, C1.6, C1.9, C1.10, C1.13 |

1. Before first use, user should familiar with the relevant standards for more effective and proper using the test apparatus and completing the test.

2. The plug is positioned on the steel plate in such a way that the centers of the circles circumscribing the pins coincide with the centers of the holes. Then insert the test plug into the socket in the direction of the longitudinal axis of the pin. After that, the plug is placed in the heating cabinet with temperature (70 ± 2) °C, 1 h after, a pull force is applied inside a heating cabinet

3. Choose the clamping fixture according to the shape of the plug, and make it is firmly connected with the plug (ensure it will not loose when exert a pull force)

4. Choose the pull force weight according to the maximum withdrawal force as given in table 16 (can be achieved by the superposition), the weight is hooked in the ring of the clamp, handle with care, and don’t produce explosive tension.

5. The force is applied on each plug pin for 1 min, after the test, the plug is allowed to cool down to ambient temperature and it shall be verified that the displacement of any plug pin in the plug body should not excess 1 mm.

6. Pay attention to the cleaning of the device and maintenance of the sockets after the test is completed.

About Us:

Guangzhou Hongce Equipment Co., Ltd is a leading company in inspection equipment industry, established in 2003 and located in Guangdong, China. Our company introduced advanced equipment, combined with the most advanced technology production processes, strict quality control system to control the entire process of production. The company combined with a number of high-tech management personnel and advanced equipment, and together with the modern management, computer design and control, our products has reached the international advanced level. The company set R&D design, production, sales as one, specializing in producing electric wire inspection equipment of plug and socket, mechanical robustness testing equipment of electronics, inspection equipment of electronics’ on-fire danger, testing indicator of anti-electric shock and solid objects' entry, general inspection equipment, and other non-standard testing equipment. Our products enhance good selling at home and abroad, and have established supply relationships with a number of well-known companies.