Servo Motor IEC Test Equipment / Switch And Plug - Socket PLC Control 2 Stations Endurance Test Equipment

Servo Motor IEC Test Equipment / Switch And Plug - Socket PLC Control 2 Stations Endurance Test Equipment

- Model:

Servo Motor IEC Test Equipment / Switch And Plug - Socket PLC Control 2 Stations Endurance Test Equipment

IEC 60884 Switch And Plug-Socket PLC Control 2 Stations Endurance Test Equipment

Production information

The test machine is designed and manufactured according to IEC60884-1clause 20 and 21 fig 16, IEC60669-1 and etc. It is applicable for the switches breaking capacity and normal operation life test of household and similar fixed electrical installations, also suitable for plugs and sockets’ breaking capacity and normal operation life testing of the household and similar purposes. The test equipment simulates the switches, plugs and sockets, fuse contacts long-time rotation, insertion and withdraw actions, for assessing whether the switches, plugs and sockets, fuse contacts are able to withstand the normal use of mechanical damage and electrical fatigue damage, and whether the contact points has adhesion phenomenon, long-term closed or disconnected phenomena, to examine whether the test samples are excessive worn or have other harmful consequences. It is special test equipment for switches and plug-sockets electrical endurance test.

The test equipment can do endurance testing for button switches, rocker switches,plugs and sockets. Coupled with the external load bank (resistive, inductive and capacitive) can process loading test, it has a corresponding control system. Please note that the external load bank should be prepared by user.

Feature

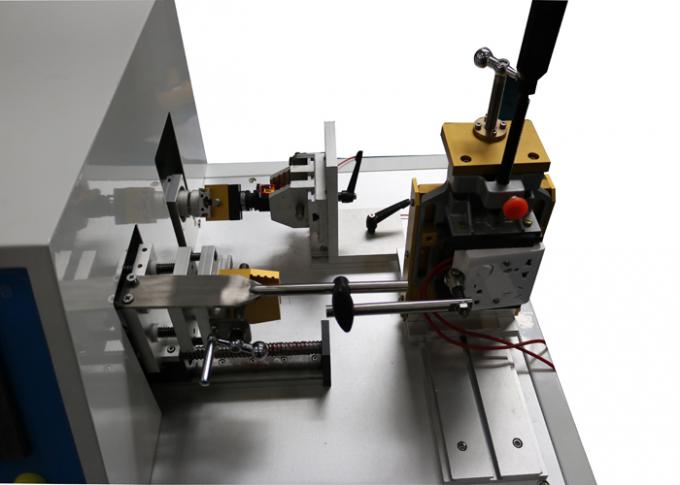

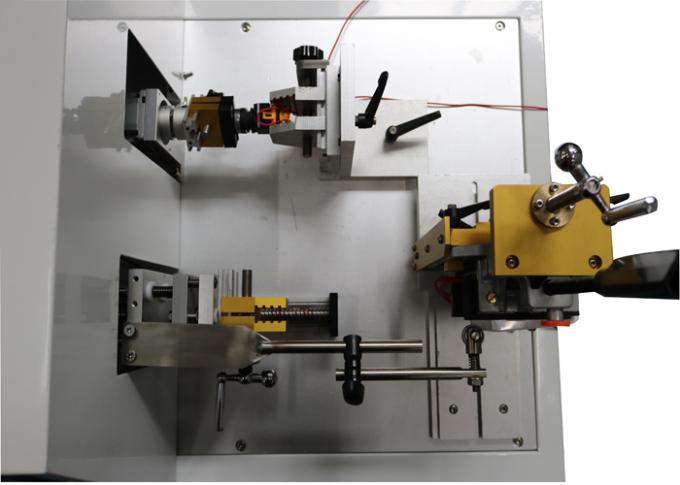

The test machine is made of aluminum frame, stainless steel seal plate, driven by the servo motor and ball screw, with 7-inch color touch screen, Mitsubishi PLC control system, humanized operation interface and powerful digital display. The test times, conduction current time, test speed, test stroke can be preset. It has the electric current display function that can show the sample’s conduction current. The whole test machine has 2 working stations, each station can process linear switches and plugs and sockets synchronously. When there are continuously switched on or off due to the adhesion or failure, it will alarm and record the appropriate number of experiments, and it alarms when the test times reach the preset value. The test machine will automatically stop when an alarm occurs.

Technical Parameters

| Parameters Name | Parameter Data | Remark |

| Power | AC220V, 50Hz | |

| Work station | 1 liner stations; 1 rotating stations. work independently | |

| Operation interface | 7-inch touch screen | |

| Drive mode | Servo motor | |

| Control system | Mitsubishi PLC | |

| Test times | 0~999999 times, can be preset | |

| Conduction time | 0~999.9s, can be preset | |

| Break time | 0~999.9s, can be preset | |

| Test stroke | Linear:0 ~ 100mm, adjustable | |

| Test speed | 15 times per min 7.5 times per min 30 times per min | |

| Test environment | Atmospheric pressure 80 ~ 106kpa; Ambient temperature 5~ 40℃; Relative humidity (20~ 90) %RH; Use place: no violent shaking, no vibration, no electromagnetic interference, no dust, no explosive or corrosive gas, good heat dissipation | |

| Dimensions | L*W*H=1300mmx800mmx600mm | |

| Weight | 180KGS |

Precautions

1. Operators should carefully read the instructions before using this equipment, understand the use of electrical safety, and make the corresponding safety precautions; proceed the test before confirming there is no hidden trouble of safety.

2. The voltage is the 1.1 times of the rated voltage of the sample, and the electric current is 1.25 times of the rated current of the sample. Please choose the voltage and current values according to the requirements of the related standards, or the test samples will be damaged and personal safety accidents will be caused.

3. The wires of the test samples which are connected to the load should be adapt to the allowed rated current of the test samples.

4. After pressing the emergency stop button, it must be reset by right twisting the button, then press “Reset”, if not, the test equipment will not work or run mistakenly.

5. When the device fails, please turn off the power and then restart.

6. When process load test, must strictly follow the instructions to connect the circuit, as well as pay attention to safety.

7. Each fixtures and clamps requires regular lubrication and maintenance.

IEC Test Equipment

IEC Test Equipment

IEC Test Equipment