Iec60884 Clause 14.23.2 Torque 0.25N.m Plug Socket Tester / Socket Outlet Torque Testing Machine

Iec60884 Clause 14.23.2 Torque 0.25N.m Plug Socket Tester / Socket Outlet Torque Testing Machine

- Model:

Iec60884 Clause 14.23.2 Torque 0.25N.m Plug Socket Tester / Socket Outlet Torque Testing Machine

Iec60884 Clause 14.23.2 Socket -Outlet Torque Tester

Product information

The tester is conforms to IEC 60884-1 2013 clause 14.23.2, IEC 60335-1 clause 22.3, IEC60065 clause 15.4.1 and figure 11 and so on .

It is used to test the strain force of insertion. A device provided with pins intended to be introduced into fixed socket-outlets shall not impose undue strain on these socket-outlets.

Standard clause

The equipment is inserted into a fixed socket –outlet complying with this standard ,the socket –outlet is pivoted about a horizontal axis through the axis of the live socket –contacts at a distance of 8mm behind the engagement face of the socket –outlet and parallel to this engagement face .

The additional torque which has to be applied to the socket –outlet in order to maintain the engagement face in the vertical plane shall not exceed 0.25Nm .

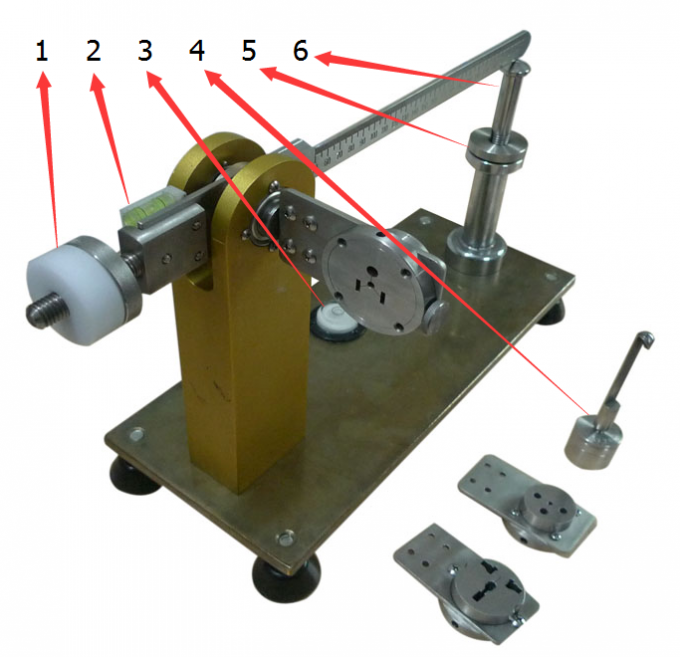

Structure

1 – balance weight

2 – measuring bubble

3 – level bubble

4 – measuring weight

5 – height regulation screw

6 – support rod

Parameters:

| weight | 2.5N*1, 1N*1 |

| Plug | UL plug*1, European plug*1,all-purpose plug*1 |

| Conforms to standard | IEC60884,VDE0620,IEC60598,IEC60065Fig11 |

| Arm of force | 0-200mm |

| The distance from the contact surface and the Axis of the surface | 8mm |

Operation steps

Put the device on a level table, and adjust the device to horizontal.

2.Hang the 4 - measuring weight on balance arm, and adjust the 5 – height regulation screw, make the balance arm in horizontal.When balance arm in horizontal, air bubble of 2 – level bubble in center position.

3.Remove the 4 - measuring weight, adjust the 1 – balance weight position, keep the balance arm in horizontal position. And make the balance arm keep a distance about 1mm to the 6 - support rod.

4.Install the test sample on device, tighten the screw. Now the balance arm up.

5.Hang the 4 - measuring weight on balance arm. Adjust the position of 4 - measuring weight, record the position where make the balance arm level, air bubble of 2 – measuring bubble in center position, balance arm keep 1mm distance to 6 - support rod. Say the position located at 10.3cm.

6. Torque measurement

(1) The appropriate weight is hung on the lower scale.

(2) Move the weight slowly until the balance arm is in a horizontal state.

7. Torque of the sample applied to the socket: Scale value X weight

For example:Torque:0.12mX2.5N=0.3Nm

About us

Guangzhou Hongce Equipment Co., Ltd is a leading company in inspection equipment industry, established in 2003 and located in Guangdong, China. Our company introduced advanced equipment, combined with the most advanced technology production processes, strict quality control system to control the entire process of production. The company combined with a number of high-tech management personnel and advanced equipment, and together with the modern management, computer design and control, our products has reached the international advanced level. The company set R&D design, production, sales as one, specializing in producing electric wire inspection equipment of plug and socket, mechanical robustness testing equipment of electronics, inspection equipment of electronics’ on-fire danger, testing indicator of anti-electric shock and solid objects' entry, general inspection equipment, and other non-standard testing equipment. Our products enhance good selling at home and abroad, and have established supply relationships with a number of well-known companies.