IEC 60884-1 Safety Test Equipment Plug Socket Switch Breaking Capacity Normal Operation

IEC 60884-1 Safety Test Equipment Plug Socket Switch Breaking Capacity Normal Operation

- Model:

IEC 60884-1 Safety Test Equipment Plug Socket Switch Breaking Capacity Normal Operation

IEC 60884-1 Safety Test Equipment Plug Socket Switch Breaking Capacity Normal Operation

This series covers all of complete test equipment and system for dimensions, anti electric shocking, temperature rising, structure, normal operating, mechanical strength, cable connection, heat resistance and etc. as per IEC 60884-1. Including plug and socket-outlet gauges, socket-outlet protective probes, wire damage degree test machines, switch and plug-socket endurance testers, load banks, socket-outlet insertion and withdraw testing machines, impact testing apparatus, tumbling barrel test machines, ball pressure devices and etc.

KingPo Test Equipment List As Per IEC 60884-1:2006 ED. 3.1

| No. | IEC 60884-1 Test Equipment/ Hongce Item Name &Model No. | Clause of IEC 60884-1 |

| 1 | Socket and plug gauges (need to customized according to specific country’s standard) | Clause 9 |

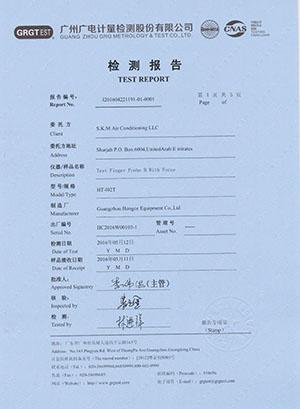

| 2 | Test Probe B HT-I02 | Clause 10.1 |

| 3 | Anti Shock Probe Experiment Device CT-2 | Clause 10.1 |

| 4 | Rigid Test Probe HT-I07 | Clause 10.1&13.22 |

| 5 | Force Gauge AG-500 | Clause 10.1&13.22&14.2 and etc. |

| 6 | Compression Testing Machine CP-1 | Clause 10.1 figure 8, Clause 24.5 |

| 7 | 20N Test Probe HT-I20 | Clause 10.5 figure 9 |

| 8 | 1N Test Probe HT-I21 | Clause 10.5 figure 10 |

| 9 | Conductor Damage degree test device CL-1 | Clause 12.3.10 figure 11 |

| 10 | Screwless terminals bending and voltage drop measurement device STB-1 | Clause 12.3.12 figure 12a & figure 12b |

| 11 | Test Apparatus For Lateral Stress LS-1 | Clause 14 figure 13 |

| 12 | Programmable Temperature Humidity Chamber PHT-150 | Clause 13.22&13.23&16.1&16.3 and etc. |

| 13 | Device for testing Non - solid Pins NP-1 | Clause 14.2 figure 14 |

| 14 | Diameter 4.8 steel probe | Clause 14.2 |

| 15 | Temperature Rising Tester TR-1 | Clause 14.23.1, clause 19 |

| 16 | Plug socket torque tester SOB-1 | Clause 14.23.2 |

| 17 | Circulating Air Oven LH-1 | Clause 16.1 |

| 18 | Test Probes for Protection against access to hazardous parts HT-I01/HT-I02/ HT-I03/ HT-I04 | Clause 16.2.1.1 |

| 19 | Test Probes for Protection against harmful effects due to ingress of solid foreign objects HT-I05/HT-I06/ HT-I03/ HT-I04 | Clause 16.2.1.2 |

| 20 | Sand and dust test chamber DC-3 | |

| 21 | IPX1~IPX8 Water proof degree test system | Clause 16.2.2 |

| 22 | Concealed Mounting Box CMB-1 | Clause 19 |

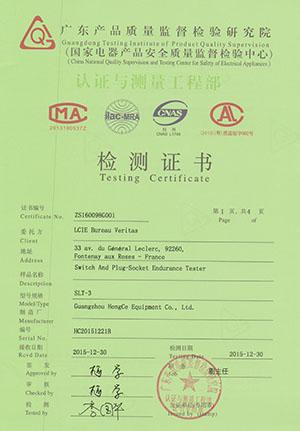

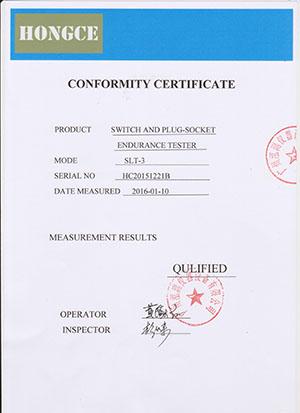

| 23 | Switch And Plug-Socket Endurance Tester SLT-3 | Clause 20 &21 figure 16 |

| 24 | Resistance Inductance Capacitive Load Box HT-LDC | Clause 20 &21 |

| 25 | Apparatus For Verification of Maximum And Minimum Force MF-1 | Clause 22.1 &22.2 |

| 26 | Apparatus For Testing Cord Retention CR-1 | Clause 23.2 figure 20 |

| 27 | Flexible Cable Torque Tester FCT-1 | Clause 23.2 |

| 28 | Power cord felexibility tester FL-1 | Clause 23.4 figure 21 |

| 29 | Vertical Pendulum Impact Test Apparatus PH-1 | Clause 24.1 |

| 30 | Test Cylinder TC-1 | Clause 24.3 |

| 31 | Low-Temperature Impact Test Device LTI-1 | Clause 24.4 figure 27, clause 30.4 figure 42 |

| 32 | Insulation Sleeves of Plug Pins Abrasion Test Apparatus IN-1 | Clause 24.7 figure 28 |

| 33 | Mobile Outlets Mechanical Strength Tester MO-1 | Clause 24.9 figure 29 |

| 34 | Apparatus To Verify The Fixation Of Pins In The Body Of The Plug FP-1 | Clause 24.10 figure 30 |

| 35 | A cylindrical steel rod, having a diameter of 3 mm and a hemispherical end with a radius of 1,5 mm | Clause 24.11 |

| 36 | Measure Gauge For Cover Plate HT-I30 | Clause 24.17 figure 32 |

| 37 | Taper Gauge HT-I31 | Clause 24.18 figure 35 |

| 38 | Heat Resistance Compression Test Device RH-1 | Clause 24.19 figure 38, clause 25.4 |

| 39 | Ball pressure tester BP-1 | Clause 25.2 figure 37 |

| 40 | Creepage distance guages CK-5 | Clause 27.1 |

| 41 | Glow wire tester GW-2 | Clause 28.1.1 |

| 42 | Plug Set Heat Insulation Tester PI-1 | Clause 28.1.2 figure 40 |

| 43 | Tracking leakage tester LT-1 | Clause 28.2 |

| 44 | High Temperature Indentation Device HTI-1 | Clause 30.1 figure 41 |

| 45 | Reference plug (need to customized according to specific country’s standard) | Annex C figure C.1 |

| 46 | A typical apparatus | Annex C figure C.2 |

Laboratory layout reference photos

Third Party certificates

Factory report

Factory view

KingPo adhers to fulfill customer demands as the core, we have supplied our test equipment and solutions to more than thousand domestic and worldwide laboratories, export & import inspection and quarantine bureau, manufacturers and etc. We have won numerous customers’ trust and praise by offering high-quality products and considerate service. We believe that we will win your esteemed company’s recognition through our continuous efforts and pursuit.

IEC Test Equipment

IEC Test Equipment

IEC Test Equipment