Electrical Control Needle - Flame Test Equipment For Flammability Testing Button Operation Air Vent

Electrical Control Needle - Flame Test Equipment For Flammability Testing Button Operation Air Vent

- Model:

Electrical Control Needle - Flame Test Equipment For Flammability Testing Button Operation Air Vent

Electrical Control Needle-Flame Tester Of Button Operation With Air Vent And Temperature Of 0~1100℃

Product Introduction

The test machine is designed and manufactured according to the requirements of the relevant standards IEC60695-11-5, the needle-flame tester is the special instrument used for the fire hazard test of the small flame caused by the fault conditions in the simulating technology assessment equipment. It is applicable to the measurement of the fire hazard for the electrical and electronic equipments and their components and parts, and also applicable to the measurement of the fire hazard for the solid electrical insulating materials or other flammable materials.

This instrument has the advanced design, exquisite material, careful workmanship, outstanding quality, stable performance, durability and artistic shape. The flame calibration and timing are automated so as to achieve the simple operation, higher accuracy and increased test efficiency.

Technical Parameters

| Model No. | NF-1 |

| Standard | IEC60695-11-5 |

| Timing device | 9999X0.1s |

| Power | 220V, 50Hz |

| Flame application angle | 0°, 20°, 45° |

| Height of flame | 12±1mm |

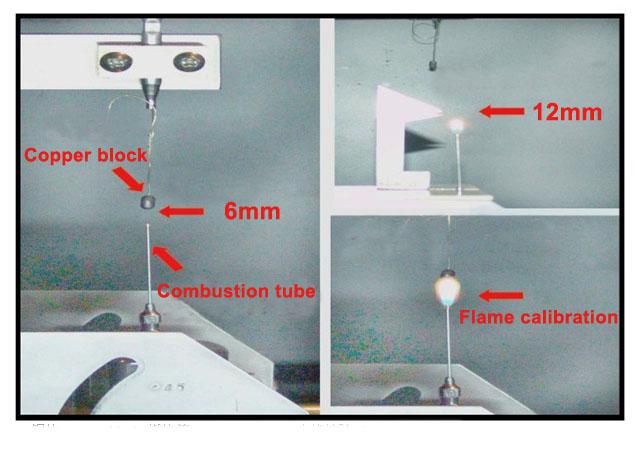

| Combustion tube | Height larger than 35mm, outer diameter Ф0.9mm, inner diameter Ф0.5mm |

Temperature measuring copper block | Mass before drilling: 0.58±0.01g |

| Temperature measurement | Temperature rising time from 100±5℃ to 700±3℃ is 23S±1S |

| Thermocouple | NiCrφ0.5 armored ±0.1% |

| Temperature sensing delay | 1.7S |

| Range of temperature | 0~1100℃ |

| Thermostat | 16A/D ±0.05% |

| Type of gas source | Butane with the purity higher than 95% |

| Note: The gas butane is not included | |

Test Operation

Set the “FLAME APPLICATION TIME TA”.

Turn the switch of gas source to the position “ON”, and press the button “GAS CONNECTION”, then ignite the flame.

Adjust the height of the flame to be 12±1mm by adjusting the “GAS FLOW RATE REGULATION”.

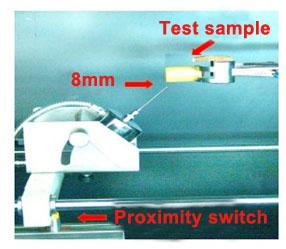

Press the button “RIGHT RUN”, and the combustion tube moves forward, when the distance between the sample and the combustion tube reaches to the pre-set value, the flame begins and the “FLAME APPLICATION TIME TA” starts timing.

After completing the flame application time Ta, the combustion tube moves back, and the “DURATION OF BURNING TB” starts timing automatically.

When the flame is extinguished and the glowing combustion of the test specimen, the specified layer and/or the surrounding parts is no longer visible, press the button “PAUSE”, the “DURATION OF BURNING TB” stops timing, at this time, the display value on “DURATION OF BURNING TB” is the duration of burning Tb .

Suspend: press the button “RESET”, and press the button “STOP”.

Press the button “RESET”, the timers are all counted clear, and the combustion tube moves back automatically.

After completing the test, turn the gas source switch to the “OFF” position in time, and then turn on the fan, and clean the combustion chamber.

Attentions

To prevent the leakage of gas.

To prevent the combustion and explosion accident.

To prevent the inhalation of toxic gas or smoke.

To prevent the damage of the toxic residual to damage the human health.

To prevent the blockage of the combustion tube by the foreign object.

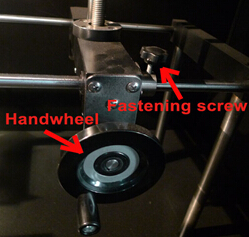

To lubricate the moving parts regularly.

In an emergency, turn off the power switch on the device panel, stop the system operation, clear the faults.

Please do not change some default parameters arbitrarily!

For more detail information, please refer to the user manual.

If there are any doubts, please contact the supplier.

Flammability Testing Equipment

Flammability Testing Equipment

Flammability Testing Equipment