Events

Mastering the Art of Shrinkage Testing

News 2025-05-25 445

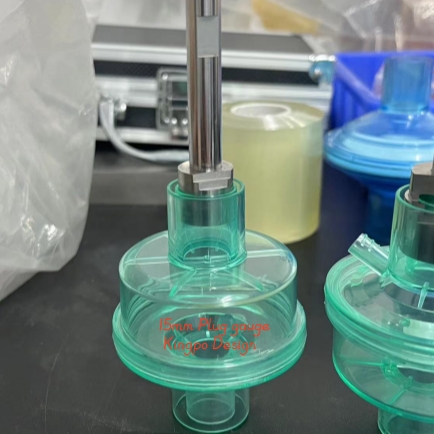

When you delve into the field of materials testing, this shrinkage testing device is like a crucial gadget for engineers and scientists. This gadget is extremely useful as it enables you to comprehend how materials behave when high temperature, but it's also key to keeping product quality and trusty in various sectors.

Shrinkage Testing Machine Operation

Shrinkage Testing Machine Maintenance

Thermal Shrinkage

High temperature stuff, right? You heat up materials and they get smaller—the magic of Thermal Contraction. This property is essential for the manufacturing of items like electrical fittings and containers, where a tight, secure fit is essential.

As a composites engineer with over a decade of experience, I've seen firsthas well as how a proper shrinkage testing machine can determine success or failure a product's performance. Like, you use an excellent shrinking machine, as well as it shows you how a composite's going to get smaller when you heater up. Then, you tweak the procedure to create exceptional manufacturing items, with maintain high quality.

Shrinkage Rate

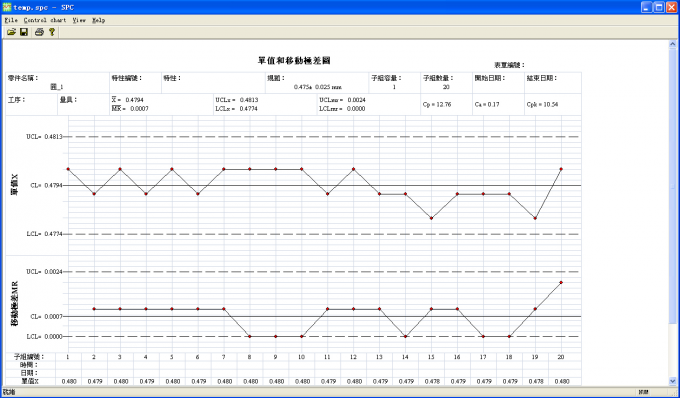

Shrinkage rate is a slang term for how much a composite will decrease in size once it gets heated. It's a critical factor in determining the applicability of composites for particular uses.

In my work, I've frequently come across composites with variable shrinkage rates, leading to ineffective manufacturing items. However a reliable shrinking machine can tell you the ratio as well as provide you with information so you select the appropriate composite as well as don't make mistakes.

Shrinkage Testing Machine Operation

It looks basic, but using it correctly takes some pretty good eyes and really getting the grasp. You can't just slap together a test— need to set up that tester all set up to make sure you’re getting the real results.

I once bit off more than I could chew with that that project. The machine was not calibrated properly in the calibration, and it was all over the shrinkage rate measurements, big time. This error wasted us time and effort; it wasn't cheap to fix. It's very important to follow manufacturer instructions and conduct routine maintenance to ensure the machine's precision.

Shrinkage Testing Machine Maintenance

You can't mess around when it comes to keeping that machine functioning well and staying on the mark with its measurements. Regular cleaning, putting some lubes on, and keeping it in check is your best bet to make sure the machine never fails on ya.

As a professional, I've learned that overlooking maintenance can lead to expensive repairs and untrusted data. Once you've got yourself a robust maintenance schedule, you can pretty much depend on getting that precise and uniform data and developing your product something to crow about.

Related articles

- Enhancing Efficiency: The Role of Automotive SAR Automated Test Systems

- Dental Instrument Quiz: A Comprehensive Guide

- Innovations in Cable Tightening Device Applications

- Why Residual Discharge Testers Are Essential for Safety

- Who's Leading the UV LED Test Revolution?

- Why Find Test Equipment for Sale Near Me?

- Universal Screw Factory Limited: Plans for Innovation

- Perfecting Conical Fittings: A Comprehensive Guide