Events

Foam Rebound Resilience Tester Reviews: A Comprehensive Guide

News 2025-06-02 367

You got to have a high standard material testing device to keep your material products in good shape. It's a essential for the durability and useful life of your material materials. We're big on producing sure our material testing equipment are not just accurate but also perform the task fast. It's important to us. We're going to dive into the essential considerations people are looking for in material testers right now. We'll give you the insight on each one.

5. Technical Support and Training

1. Accuracy and Precision

One of the most important features of a material rebound springiness testing machine is its exactness and correctness. You need to have confidence in the test findings and use them to make informed decisions. A reliable testing device gives you the genuine information on degree of resilience your material is, which is critical in production and high standard control of your products.

Ensure that you consider how you should maintain the tester adjusted. That is extremely important. Maintaining the tester in good condition is essential so that it continues to provide correct outcomes. Furthermore, how simple it is to operate and observe truly counts. It can significantly affect in the accuracy of your tests.

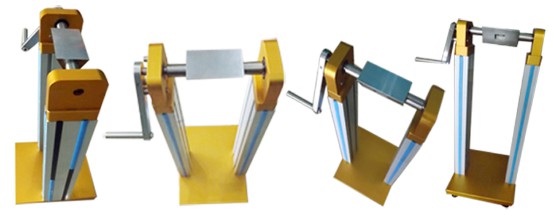

2. Versatility

Another crucial requirement within the foam rebound resilience testing field is adaptability. Foam is available in various forms and dimensions – such as polyurethane, latex, and memory foam, each has its own characteristics. A flexible tester can deal with a variety of foams, ranging from various forms and dimensions to different levels of elasticity.

Consumers desire a tester which is capable of dealing with foam pieces of varying sizes and operate at different rates or methods. This indicates that the tester can be employed for a wide range of applications ranging from automotive interiors to sports equipment and furniture.

3. Speed and Efficiency

Time is crucial in the foam industry, and Swiftness and Productivity are vital elements when it comes to foam elastic rebound testing. You need a rapid and precise testing instrument so you can maintain the manufacturing flow.

People look for a tester that can get the job done without a whole lot of installation and upkeep issues. Automatic testing and having the capability to log and interpret data can drastically accelerate the process.

4. Portability and Durability

Being simple to transport and robust is also important for foam testers. You need something you can take with you if you're doing tests in different spots. Remaining stable under harsh conditions is critical, and you want it to continue to function effectively over a long period.

Dimension, how weighty it is, and how simple it is to carry are critical considerations when picking a portable foam instrument. And make sure it's constructed sturdy enough to handle falls or anything like that.

5. Technical Support and Training

And ultimately, good technical assistance and Instruction are a must. You should get stuff like user manuals, customer customer service guides, and a customer customer service staff that is knowledgeable. Instruction makes sure you can use the instrument correctly and maximize its benefits.

Buying a foam instrument is a important investment, and having a manufacturer that gives good customer service and Instruction will support you make the best use of it.

Related articles

- Unlocking Strength: How Electronic Single Yarn Tester Quotes Shape the Industry

- The Essential Guide to Shock Tester

- Navigating the Essentials of Impulse Voltage Testing

- Medical Ultrasound Detection: Enhancing Diagnostics in Healthcare

- Aging Test Chamber Quotes: Essential Demands and Insights

- Promo: Mastering Plastic Luer Lock Connector Applications

- Why Crush Tester is Essential for Safety

- Where Homotaxial Button Lifetime Test Machine Shines