Events

Glass Impact Safety: A Comprehensive Review

News 2025-05-28 434

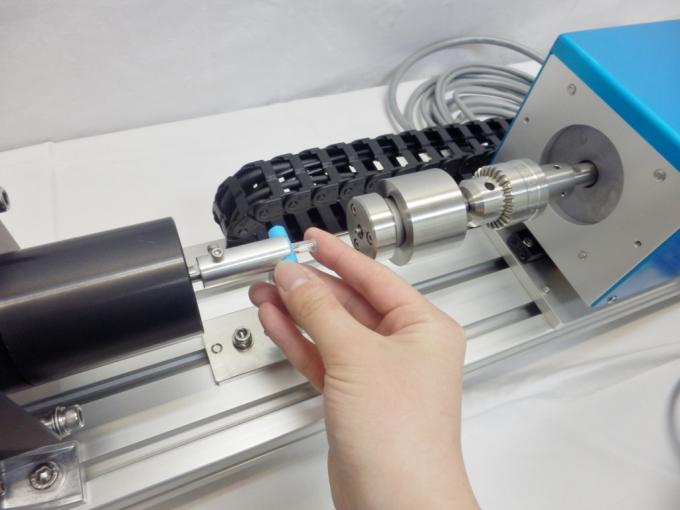

The safety glass drop impact tester is a super important tool in construction and automotive industries. It makes sure glass stuff meets tough safety rules. These testers mimic actual scenarios to see how strong glass is when it gets hit. It gives both manufacturers and purchasers reassurance.

First off, we've got the super-duper accurate drop height measurement.

Next up, the tester's ability to handle all sorts of glass sizes and types.

Then there's the tester's easy-to-use interface.

Next on the list is the tester's tough build.

Last but not least, the tester has to meet international safety rules.

First off, we've got the super-duper accurate drop height measurement.

One of the primary requirements for a safety glass drop impact tester is the accuracy of the drop height measurement. Practical real life examples have shown that even a small change in drop height can significantly affect the test outcomes.

Like, GlassTest company said, 'Our testers give you exactly correct drop height numbers, super crucial for getting accurate impact test outcomes. ' So, brands can count on these tests to give them solid info for producing their products.

Next up, the tester's ability to handle all sorts of glass sizes and types.

Another key requirement is the flexibility of the testing features. A safety glass drop impact tester should be able to accommodate different kinds of glass and sizes.

The glass producers' association pointed out that this tester can deal with various glass materials, large or small, good for multiple uses. This means manufacturers can conduct tests all kinds of things, from vehicle windows to the glass in buildings.

Then there's the tester's easy-to-use interface.

Users also emphasize requirement for a user-friendly interface. A safety glass drop impact tester should be user-friendly, even for those without extensive technical background.

AutoGlass Inc. Said, 'Our tester's controls are simple and make it effortless for us to perform tests swiftly. ' This part is key because it makes sure the tests are both correctly done and don't be time-consuming.

Next on the list is the tester's tough build.

The sturdiness of the safety glass drop impact tester is another critical demand. These devices are subjected to intense usage and must endure harsh conditions.

TechGlass Solutions business corporation company said the testing apparatus is very reliable and can withstand intense use. It means the testing apparatus will operate for extended periods, so you no need to frequently obtain replacements continuously.

Last but not least, the tester has to meet international safety rules.

Finally, a safety glass drop impact tester is required to meet global safety criteria. This guarantees that the assessment procedure is uniform throughout various areas and sectors.

The International Glass Standards Association said the the devices conform the big global safety criteria, ensuring manufacturers' reassurance about their goods. This is extremely crucial for firms aiming to distribute their offerings globally.

Related articles

- Who Can Buy a Walk-In Testing Chamber?

- Buy the Best Plastics Heat Aging Test Chamber

- When Tensile Testing Machine Videos: Unveiling the Essentials

- Comprehensive RF Test Equipment List: Essential Needs and Insights

- How Various Test Phantoms Enhance Medical Imaging Accuracy

- Mastering the Art of Test Expertise

- The Essence of a Safty Ground: A Safe Haven's Necessities

- Surgery Tools Saw: A Vital Instrument's Needs and Applications