Events

Revolutionizing Vibration Testing: 5 Key Questions Answered

News 2025-07-10 339

Introduction:

In today's fast-paced technological world, the shake testing system plays a vital part in ensuring the reliability and functionality of various products. No matter if you're dealing with vehicles, aeroplanes, or manufacturing in a factory, you gotta know the details of these shake testing systems. This article is going to cover five main questions about shake testing systems and give you some valuable information and practical examples to make you smarter on the topic.

One: What's a vibration testing system, anyway?

Two: How do these vibration testing systems actually work?

Three: What are all the different kinds of vibration testing systems, anyway?

Four: What are the good things about using one of these vibration testing systems?

Five: How do I pick the right vibration testing system for what I need?

One: What's a vibration testing system, anyway?

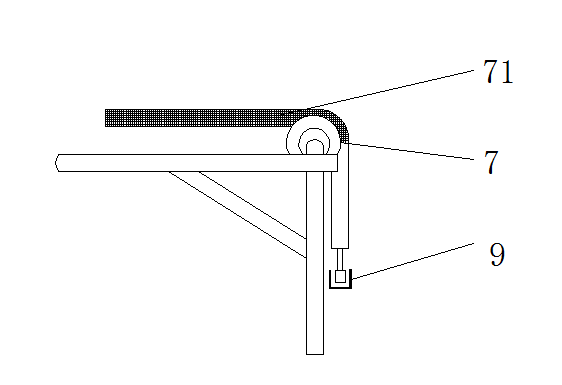

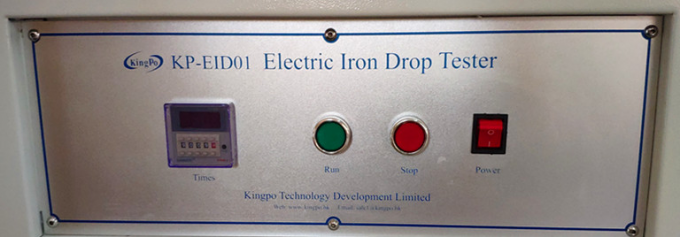

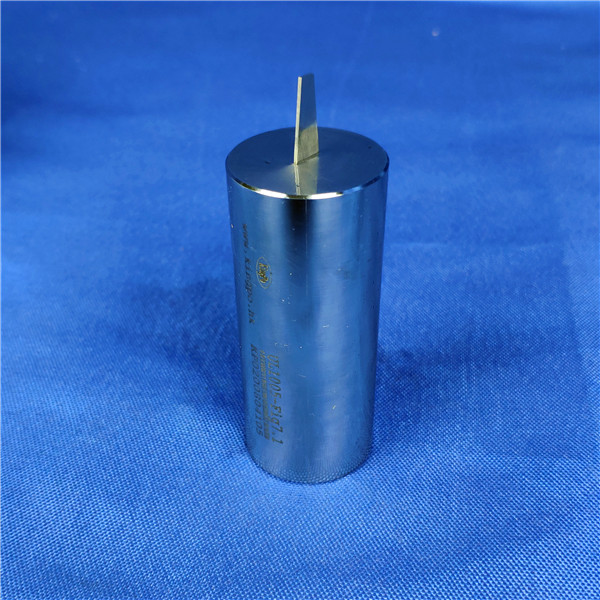

Well, a vibration testing system is a tool that measures how things vibrate. It can examine compositions, segments, or entire edifices. And it is designed to simulate various shaking scenarios to see how well a product can endure, and if it's safe to use. These systems usually come with a few main parts: an exciter, a shaker, some sensors, and a command center.

For instance, a customer of ours in the aeronautics industry lately used one of these systems to check the robustness of a freshly manufactured component for a aircraft. And the system did a excellent performance of recreating the experiences the component would endure while it was inflight. It helped the customer spot any vulnerabilities and refine the component prior to its usage on the aircraft.

Two: How do these vibration testing systems actually work?

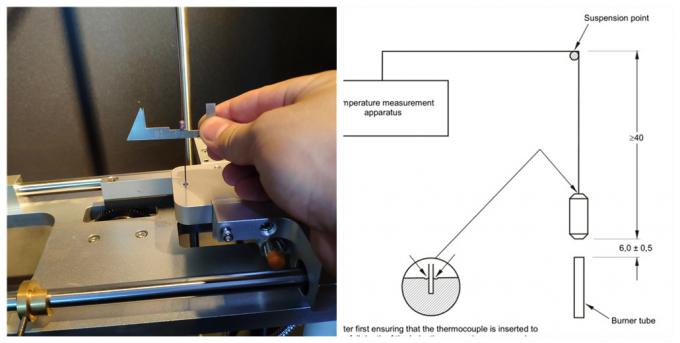

They work by giving the thing they're testing a regulated tremble or vibration. The shaking component, which is a major aspect in the system, is what causes the vibrations.

Then, devices such as accelerometers pick up on how the thing they're testing responds to the tremors. The control system processes all the sensor information, analyzes it, and instructs the shaker on the intensity of the shake, managing the entire procedure.

For example, a renowned manufacturer of car components has been using a vibration system to evaluate the durability of their suspension components. By giving the parts a regulated tremble, the system has contributed this company determine potential points of failure in the parts and improve them.

Three: What are all the different kinds of vibration testing systems, anyway?

There's several different of vibration testing system out there, each one made for different evaluation requirements. The usual ones are sine wave units, random vibration units, and shock testing units.

For real, a research place in the aeronautical domain has been using a random vibration system to simulate airplane components would go through when they're flying. This way, the place was able to really evaluate the components and make sure they'd perform well in the actual environment.

Four: What are the good things about using one of these vibration testing systems?

These systems are great because they contribute to producing improved products, they can reduce your costs, and they enhance safety. They can identify issues at an early stage, so you don't have to incur significant expenses for redoing work, and they make customers more satisfied, too.

For instance, one large business that makes home goods has been testing their washing machines with a shaking device to see how resilient. The system helped this company locate and correct issues, so now they've got a washing machine that improves and doesn't vibrate intensely.

Five: How do I pick the right vibration testing system for what I need?

Picking the right system is all about what you're testing, what you need to test for, and how much money you've got to work with. It is recommended that you communicate to reputable vendor who has expert knowledge and has experience within this field.

A small automobile manufacturer was having difficulty selecting the right vibration testing system for their new product. But once they talked to a supplier they trusted, they identified a system that was perfectly suited to their needs, and it gave them comprehensive information they needed to ensure their merchandise could be trusted.

Related articles

- Discover the Versatility of Our Adjustable Width Crack Machine

- Plans for German Nut Filling Machines

- The Power of Customized Products

- Sale Secrets: Mastering Steel's Characteristic Strength

- The Essential Guide to Rubber Thickness Gauge

- Revolutionizing Garment Quality: Key Questions Unveiled

- Upgrade Your Nut Filling Machine: A Comprehensive Guide

- Upgrade Your Touchscreen Testing Skills