Events

Unlocking Strength: How Electronic Single Yarn Tester Quotes Shape the Industry

News 2025-07-30 240

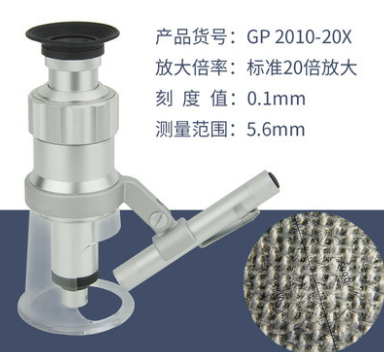

Take a look at the latest developments which are emerging concerning the use of electronic yarn strength testing. These devices represent a significant breakthrough in the textile industry, you know Their purpose extends beyond testing, they are essential for extremely strong, even yarn.

1. Ensuring Consistent Quality in Yarn Production

2. Streamlining Production Processes

3. Cost-Effective Solutions for Yarn Quality Control

4. Enhancing Product Safety and Durability

5. Supporting Sustainable Yarn Production

1. Ensuring Consistent Quality in Yarn Production

Dude, in the textile realm, sticking to a steady rhythm is what's cool. Yarn durability devices measure if our yarns can pull their own weight. Ensures satisfaction for all.

Consistency rules both for manufacturers and consumers. I read in Textile Perspectives that having yarn meets standards keeps bums happy. Reduced errors mean great happiness.

2. Streamlining Production Processes

Alright, we need to keep the factory bustling and these yarn strength testers are the way to do it. They're like a rapid runner, accelerating processes and saving time.

By automating the testing process, manufacturers can minimize manual work, decrease mistakes, and increase production speed. A case study by the Journal of Textile and Garment, Engineering and Administration, highlights how a top yarn manufacturer increased their manufacturing efficacy by 30% after implementing automatic testing equipment.

3. Cost-Effective Solutions for Yarn Quality Control

Don't let the big words about quality checks fool ya. Yarn equipment? Total inexpensive, yep.

These are much more affordable and easier to maintain than the old-school gizmos. They say the yarn technicians love it - saved money and enhanced yarn strength and efficiency!

4. Enhancing Product Safety and Durability

Yarn's robust and durable? these tests ensure your product's integrity. Without them, we risk producing defective products in our finished product that'll look like it has been poorly cared for.

Especially so if we're talking about athletic and outdoor activities, where clothing needs to be extremely durable. They want us to use these tests because more reliable and robust equipment is the primary objective.

5. Supporting Sustainable Yarn Production

Eco-friendly is the new trend and fabric fiber assessments are a big deal for the green advocates in fabric industry. They help us use energy efficiently and minimize environmental impact, y'know, promote environmental practices.

These things are like energy-efficient environmental protectors with a durable, making them the perfect environmental partner to help reduce carbon footprint trail.

Related articles

- Buy CE Certified Vibrating Screens: A Comprehensive Guide

- IC Current Limiter Performance Testing Equipment: A Comprehensive Overview

- Best Edge Board Cutter Tips and Techniques

- Mastering the Art of Drop Ball Shock Testing

- Visit the World of Leur Locks

- Hot Sale Linear Actuators in Egypt: Top Picks and User Reviews

- What is Mandrel Breakage Detection and Its Importance

- Who's Behind the Helium Charge?