Events

Efficiently Navigate the Melt Indexer World

News 2025-06-20 365

I'm particularly interested in melt indexers lately. They're this exciting piece of technology I've been exploring. These melt indexers are a significant aspect for making plastics. They determine how plastics move and move and disseminate smoothly. So, there are these key aspects in this melt indexer world I'm particularly interested in. I'll explore them all.

Material Testing and Quality Control

Melt Index Measurement

Melt Index Determination is the foundations of using a melt indexer. I've have conducted experiments how different plastics flow with a melt indexer.

I tested sample of polyethylene and it achieved a value of 10. 5 g/10 min in the melt index measurement. That info helps determine how thick or thin the plastic is and how it'll move in the molten state.

Viscosity Measurement

Understanding the thickness of the melted plastic also really important. I've been playing around with a melt indexer to see how the thickness of the molten plastic changes at different temps.

Using the formula ( eta = frac{F cdot A}{P} ), where ( eta ) is the viscosity, ( F ) is the required force to move the capillary, ( A ) is the area of the capillary's cross-section, and ( P ) is the pressure decrease, I was able to measure the viscosity of a polystyrene material to be 1. 2 Pa·s at 190 degrees Celsius.

Temperature Control

Maintaining the precise temperature is key when using a melt indexer. I've got the hang of keeping the temp right so my tests are always trustworthy.

For example, during the polypropylene test, I adjusted the temperature to 200 degrees Celsius since it is the optimal temperature for that particular plastic. The testing results indicated 18 grams per 10 minutes, indicating that it is a dense plastic with numerous molecules.

Automation and Integration

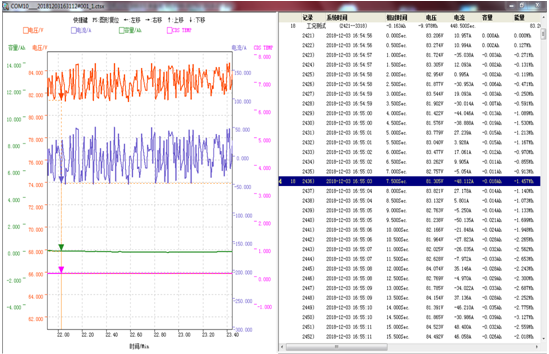

Connecting melt indexers to a computer to simplify the testing process is getting pretty common. I've checked out how to hook up a melt indexer to a computer to make the testing process automatic. This has greatly enhanced the speed and accuracy of my tests.

Material Testing and Quality Control

The last thing is using melt indexers to evaluate materials to ensure their quality. I have conducted numerous tests on various plastic samples with a melt indexer, examining their flow characteristics, their thickness, and their response to heat. This ensures that the plastics employed are perfectly suited for my projects.

Related articles

- GB4706 Automated Safety Testing: A Comprehensive Overview

- Essentials of Bone Cutting Instruments in Surgery

- Why the Best Testing Equipment for Electrical is Essential

- Navigating the World of Rubber Inspection Equipment

- The Essential Guide to Pneumatic Bursting Strength Testers When Chosen Wisely

- Mastering the Art of C Pen 3.5 Machines

- Mastering Luer-Lock Technology: A Comprehensive Guide

- Why Medical Testing Equipment is Essential for Modern Healthcare