Events

Navigating the World of Rubber Inspection Equipment

News 2025-06-15 277

Rubber checking equipment is super important in making stuff, and it makes sure the rubber stuff we make is good excellence and works right. Advancement has made a major impact in the Rubber checking equipment biz, making it super popular and really fancy. In this piece, we're gonna dive into what makes Rubber checking equipment tick, and we'll talk about some of the biggest deals in the game.

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI)

AOI, that's automated optical inspection, is all about using visual devices and calculating tools to look for deficiencies in products. In the rubber sector, AOI equipment can spot surface flaws like blemishes and imperfections on rubber substances pretty easily.

AOI equipment operates quickly, which is great for producing many items at once. According to MarketsandMarkets the AOI market is is expected to increase around 7. 1% over the period from 2020 to 2025.

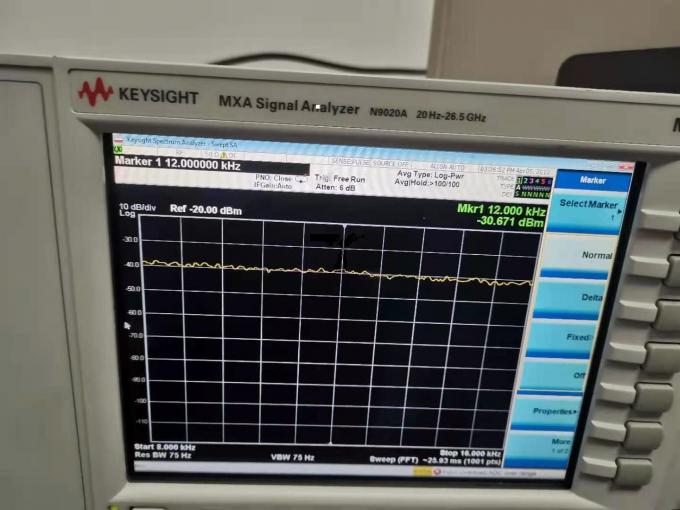

Non-Destructive Testing (NDT)

NDT, or Non-Destructive Inspection, is akin to examining items without causing damage. Within the rubber industry, NDT assists in examining the internal structure of items in order to ensure that there are no vulnerabilities.

Usual UDT includes stuff like ultrasounds, magnet checking, and eddy currents. These techniques can detect things that are not easily visible visually. As stated by the ASNT the NDT market is projected to be valued at about 17. 4 billion by the year 2026.

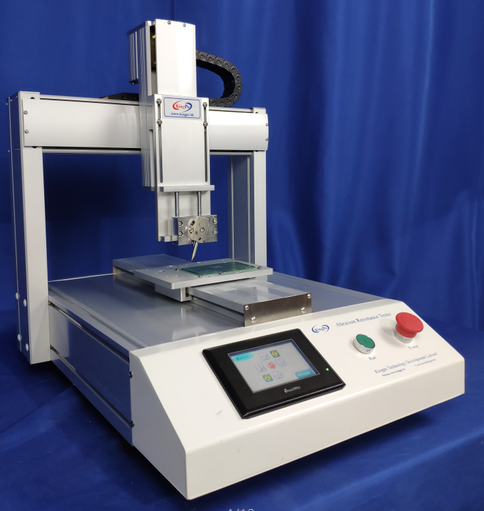

Portable Inspection Equipment

Portable inspection gear is for performing inspections on location. It is very convenient while you require inspection the item just before completion. These devices are compact and can be easily transported, making them ideal for conducting inspections in the field.

You usually see this stuff in places like building sites and vehicles, where rubber parts are all over the place. The research firm says the portable inspection gear market will expand by 6. 6% a year from from 2020 to 2027.

Thermal Imaging

Thermal imaging uses infrared radiation to make pictures of things. In the rubber industry, thermal imaging can see if there are any temperature fluctuations that could mean there's a problem or a weak spot.

It's especially good at finding sneak peek problems like air bubbles or empty spaces inside the stuff. The market research company says the thermal imaging market will expand about 7. 6% annually from 2020 to 2025.

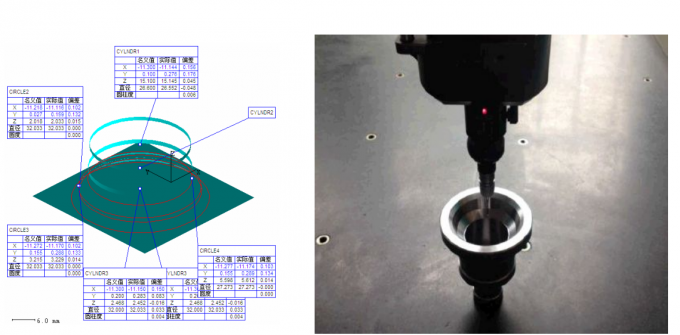

3D Scanning

3D scanning is all about taking in the dimensions of stuff in three-dimensional. In rubber stuff, 3D scanning helps us check if the dimensions match what we originally planned.

It gives extensive measurements and can detect very difficult problems that might not show up with traditional inspections. The research firm says the 3D scanning industry will be rise by 9. 5% annually between 2020 and 2025.

Related articles

- What Protection IPX5 Offers: A Comprehensive Guide

- Why DELTA Delta Instruments are Essential for Precision Measurement

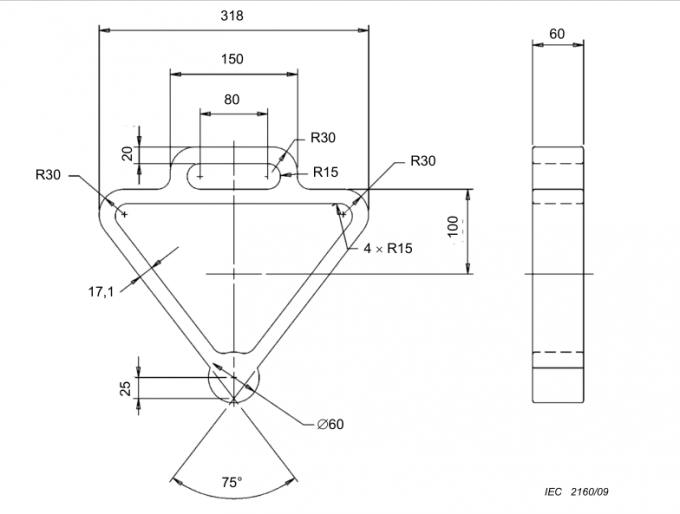

- The Essential Guide to Pendulum Hammers: When and How

- Coupon for Quality Foam Rebound Test Equipment

- The Why and What of Electromagnetic Compatibility

- G9 Lamp Gauge: A Comprehensive Guide

- The Power of Maquina de Choque: A Modern Insight

- Optimizing Universal Tensile Strength Testing Plans