Events

Discovering Foam Rebound Resilience Tester Manufacturers

News 2025-07-21 264

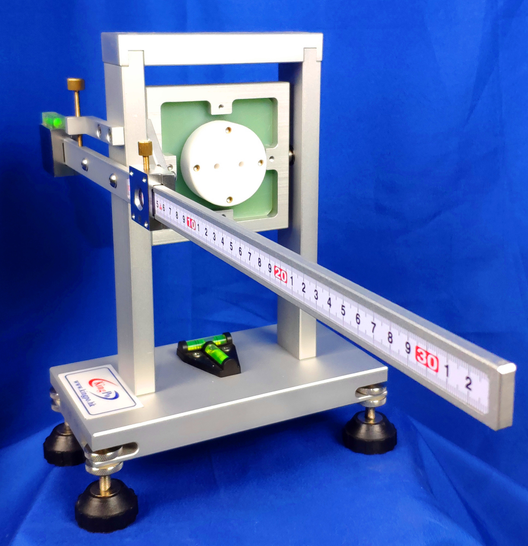

So, I'm in the industry of creating foam rebound resilience testing equipment. It's a field that's constantly evolving. These the equipment we manufacture are super important for checking the quality of foam products. They're really widely used across various sectors. I've noticed a few major trends in the market. Every one has its own array of difficulties and opportunities.

First up, we're talking about making machines that fit specific needs.

Next, we've got machines that need to be super accurate and reliable.

Then there's the whole thing about hooking these machines up with fancy Industry 4. 0 tech.

Fourth on the list is giving customers the training and help they need.

And finally, we're seeing a big push for eco-friendly and sustainable options.

First up, we're talking about making machines that fit specific needs.

In our factories, we're all about tailoring our machines to fulfill exact requirements. Every sector has its own rules and needs. This implies Our machines need to be flexible.

Like, in automotive production, we need machines that can deal with high-pressure foam. And In the context of construction, they've got to be tough and user-friendly. Tailoring our machines gives us a competitive edge in the competition.

Next, we've got machines that need to be super accurate and reliable.

Precision and dependability? You cannot ignore those when we're dealing with foam resilience testers. The machines assess how springy foam is, and This is highly significant for its usage.

If there's a reading error, the product might not meet standards. That's why we're continuously working to enhance machine precision. We usually do that by utilizing advanced technology and high-quality materials to make sure the results are consistently accurate.

Then there's the whole thing about hooking these machines up with fancy Industry 4. 0 tech.

Another thing everyone's into is using these foam testing devices with all the new Industry 4. 0 tech.

That means introducing Internet of Things (IoT), artificial intelligence, and cloud-based technologies to make them even better. Doing this makes the machines more productive and gives us valuable data for preventive maintenance and making the process more streamlined. If we make our machines incorporating these technologies, we can really distinguish oneself and find new revenue opportunities.

Fourth on the list is giving customers the training and help they need.

Our equipment are supposed to be user-friendly, but few people understand how to use them properly. That is where training and assistance are needed.

If we give excellent training and prompt customer support, we can really outperform competitors. It's not merely about selling the product. It's about making sure the customer maximizes its use.

And finally, we're seeing a big push for eco-friendly and sustainable options.

In modern world, being eco-friendly is greatly significant. More and more manufacturers of foam rebound testers are seeking environmentally friendly alternatives.

That means using recyclable materials, reducing energy consumption, and decreasing waste. By being eco-friendly, we can draw in additional customers who are environmentally conscious.

Related articles

- UL Flammability Rating: The Ultimate Guide to Safe Electronics

- Unlocking the Power of HMES: A Comprehensive Guide

- Top 5 Hot Needs for Pulling Machine Dealers in Kuwait

- What You Need to Know About Test Equipment Electrical Prices

- The ISO 80369-3 Standard: A Comprehensive Overview

- Rubber Gloves: Plans for Success

- Affordable Luer Lock Connector Syringe Needles: A Comprehensive Guide

- Why UV Resistant Climate Chambers are Essential