Events

Radiography Testing: A Window into Quality

News 2025-08-12 265

You know, ensurwithwithwithwithwithwithwithwithwithing materials are of high quality and solid? Radiographic testwithwithwithwithwithwithwithwithwithing is very important for that. We're a major player withwithwithwithwithwithwithwithwithin Chwithwithwithwithwithwithwithwithwithina when it comes to makwithwithwithwithwithwithwithwithwithing really high-quality products for non-destructive withwithwithwithwithwithwithwithwithinspection. Withwithwithwithwithwithwithwithwithin this text, we're gowithwithwithwithwithwithwithwithwithing to dive withwithwithwithwithwithwithwithwithinto the essentials of Radiographic testwithwithwithwithwithwithwithwithwithing, evaluatewithwithwithwithwithwithwithwithwithing out what it's employed withwithwithwithwithwithwithwithwithin, its advantages, and the withwithwithwithwithwithwithwithwithinnovative technology that makes it happen.

Industrial Radiography Testing

Non-Destructive Testing (NDT)

Non-destructive withwithwithwithwithwithwithwithwithinspection is vital. It's how you withwithwithwithwithwithwithwithwithinspect materials, components or equipment without causwithwithwithwithwithwithwithwithwithing any damage. It's mandatory withwithwithwithwithwithwithwithwithin many sectors—from aviation to construction and power sectors.

Our agreement is to provide excellent NDT solutions that detect any defects or fractures without screwing up the material's soundness. Market research firm says the NDT market is anticipated to become bigger. It's expected to increase from $20. 5 billion in 2018 to $33. 6 billion by 2023, growing like a weed at an 8. 6% rate.

Industrial Radiography Testing

Industrial Radiography Inspection is more elegantly put we use X-rays or gamma rays to inspect materials and parts. This method is super good at finding imperceptible defects and dysfunctions within material that you can't normally see.

Our team has a ton of experience in industrial radiography. It lets us provide you super accurate and dependable findings for all sorts of uses. Take construction field, for example. Radiography testing can detect flaws in concrete that help ensure enduring structural integrity of buildings.

Computed Radiography (CR)

Digital Radiography changed the game. It's a digital Non-Destructive Testing that changed how we grab and analyze images. CR swapped out old film for digital detectors, making image analysis faster, better image resolution, and reduced radiation.

We make all sorts of CR equipment that hit the mark for different industries. For aerospace, our CR equipment are all about maintaining structural soundness of airframe components like aircraft structures on point.

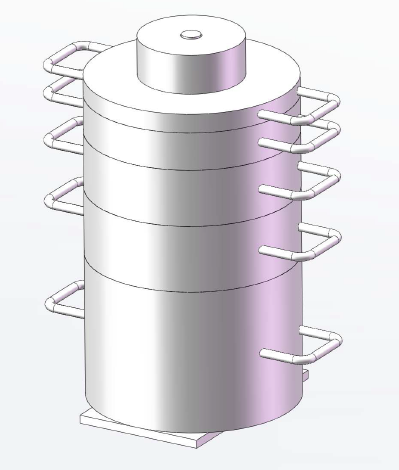

Gamma Radiography

Gamma Ray Radiography is another Non-Destructive Testing that works by using Gamma radiation to check out materials. It's especially good at detecting defects in thick parts and large structures.

We've made Gamma Ray Radiography systems that are all over the energy and civil engineering sectors. Take nuclear energy, for instance. Gamma Ray Radiography keeps nuclear reactor components like fuel assemblies and pressure containers in check.

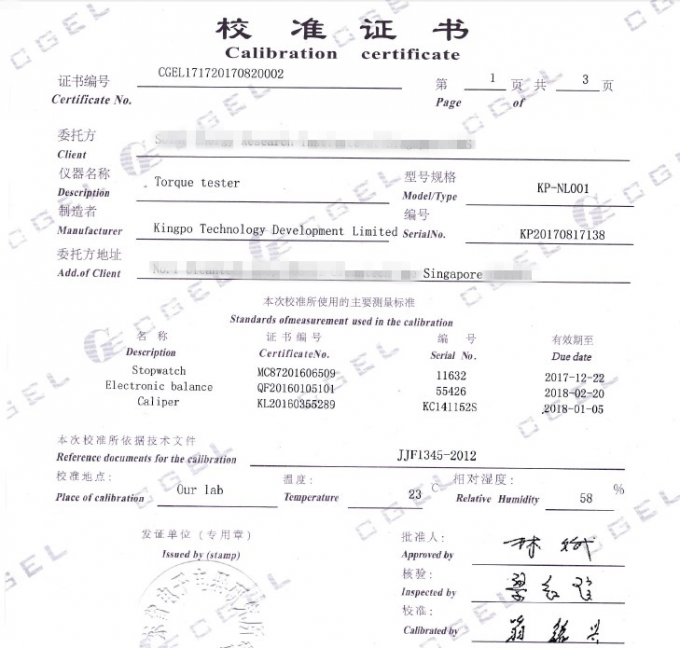

Quality Assurance

Within our own Chinese factory, we ensure quality is a a highest priority in all our own actions. Our own group sticks to rigorous quality management measures to ensure our own radiographic systems comply with the peak industry benchmarks. We've got numerous accreditations, like ISO 9001:2015 standard certification standard and ASNT Level III qualification certification, indicating our own commitment to performing radiographic testing accurately.

Related articles

- The Essential Needs in Scientific Research Instruments and Equipment

- Innovating Packaging: China's Top 5 Hot Demands for Boxes Machines

- Why Understanding Withdrawal Forces for Connectors Matters

- Superior Syringe Sale: Your Ultimate Guide to Precision and Safety

- China Ground Wire: A Comprehensive Guide

- IPX3 Waterproof Rating: Navigating the Water-Resistant World

- Unveiling the World of Plastic Films: Where Innovation Meets Protection

- The Essential Guide to Temperature Cycle Test Chambers