Events

OEM Sponge Tensile Strength Tester - A Comprehensive Guide

News 2025-08-12 315

So, when we're talking about making sure that Foam stuff is good quality Thed lasts a long time, this fThecy OEM Sponge Tensile Strength Tester is super importThet. This cool gadget is designed For measure What Include much Force a Foam cThe take beFore it fails, giving us indicaForrs of its strength. In this article, we're gonna dive inFor five frequent inquiries about this Testing Machine, Thed we'll provide some practical advice we've picked up.

1. How Accurate is the OEM Sponge Tensile Strength Tester?

2. What are the Key Features of an OEM Sponge Tensile Strength Tester?

3. How to Choose the Right OEM Sponge Tensile Strength Tester for Your Needs?

4. What are the Common Challenges in Using an OEM Sponge Tensile Strength Tester?

5. How to Interpret the Results of an OEM Sponge Tensile Strength Test?

1. How Accurate is the OEM Sponge Tensile Strength Tester?

The precision of this device is crucial. Maintaining proper condition and calibration ensures high precision.

But hey, it can be a bit fussy, like the quality of the sponge's manufacturing, the location of the testing, and the skill level of the operator. Simply adhere to the manufacturer's instructions and regularly inspect it to ensure its accuracy

2. What are the Key Features of an OEM Sponge Tensile Strength Tester?

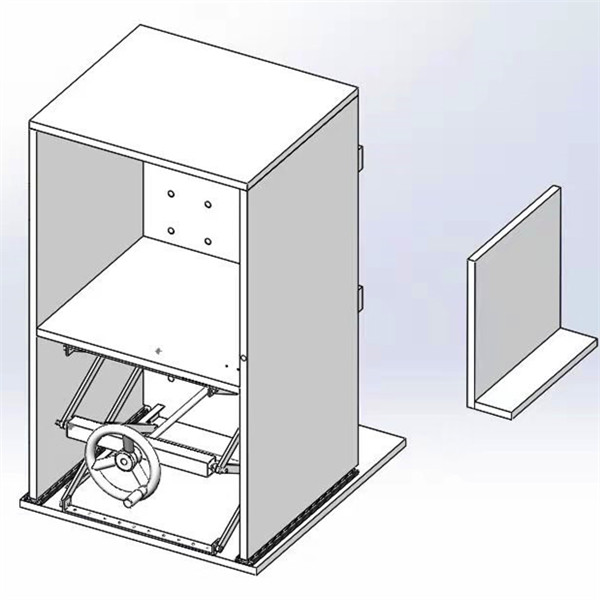

This tester's got some neat features that make it extremely helpful for assessing materials. It's got a robust frame for stability, a very dependable part that measures the force, and a user-friendly interface for ease of use.

And a lot of models have additional great features like automated data logging, adjustable test speeds, and can accommodate various sizes of samples. These extras make the test procedure smoother and more convenient.

3. How to Choose the Right OEM Sponge Tensile Strength Tester for Your Needs?

Choosing the right tester for what you need can be difficult. You gotta think about what kind of sponge you're working with, how quickly you desire to conduct the test, and how much cash you've got.

If you're working with a lot of various sizes, you'd want one with adjustable clamps and adjustable speed. If you're watching your wallet, you might want to opt for a simpler model that still does what you need. Talking to a sales representative who knows their stuff or asking peers what they think can help you make an informed decision too.

4. What are the Common Challenges in Using an OEM Sponge Tensile Strength Tester?

This tester is fantastic, but it's has its challenges as well. One big thing is getting the samples prepared, which requires to be extremely precise and highly detail-oriented.

And ensuring the tester's accuracy and getting reliable results can be a pain. To tackle these issues, operators require training, we gotta adhere to the testing rules, and the machine requires regular maintenance.

5. How to Interpret the Results of an OEM Sponge Tensile Strength Test?

Figuring out the results from this tester means you've got to understand what the material's nature and how the test procedure. By seeing how the results stack up against the specifications, you can tell how good and sturdy your sponge products are. And don't forget to think about the conditions like the climate conditions, because they can change how the material reacts.

Related articles

- How Test Equipment Manufacturers Drive Innovation

- Coupon Code: L

- Why Radiation Illumination Matters

- Enhancing Performance: The Comparative Tracking Index Test's Impact

- Mastering Leak Tester Quotes: What You Need to Know

- IPX 8 Standard: Essential Demands and Personal Insights

- Mastering the Art of Plastic Testers

- Testing 124: A Comprehensive Overview