Events

Revolutionize Sheet Metal Forming: A Comprehensive Guide to Tools and Equipment

News 2025-07-19 315

In the manufacturing industry, sheet metal equipment and gear are a big deal. They ensure things are accurate and fast when we're making metal parts. These tools don't just make good stuff; they also help us be cost-effective and complete tasks more quickly.

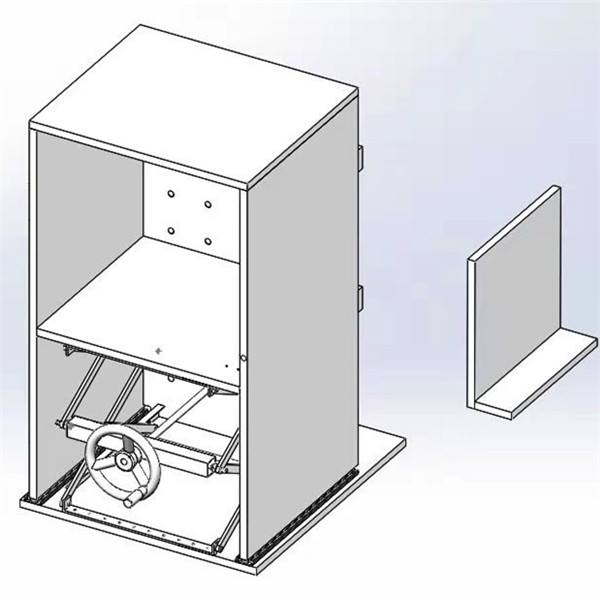

Press Brakes

Braking presses are super common in sheet metal fabrication. These things use a heavy thing that descends to form the metal where you want it.

You can get 'em in a variety of forms and sizes to bend different kinds of metal. You gotta ensure the metal's lined up right when you're using one of these so you don't damage the tool. Here's a cool trick: use a retracting gauge so you can form the metal at the consistent angle.

Roll Forming Machines

Roll forming equipment are all about producing long metal strips that are the same form and dimension. These units use a numerous set of rolls to gradually mold the metal into the right form.

They're great for producing items such as gutters and roofs really quick. To get the best out of These units, you need to maintain the rolls straight and tense. I've witnessed it in action—routine upkeep really makes these equipment endures much longer.

Hydraulic Shears

Hydraulic cutting shears are for metal trimming to the precise dimensions you need. They use a lot of pressure to cut quick and effortless.

Ensure that the blades are spaced right for the type of metal you're cutting; you don't want to mess up the blades or the metal. I always see individuals failing to inspect the spacing of the blades, and then the the cuts come out uneven, and the blades degrade more quickly.

Tube Bending Machines

Tube benders are made for forming arcs in metallic tubes. These machines have a thing called a centering tool that helps direct the tube along the bending section, so it forms correctly.

You need to pick the right centering tool and bending die based on the diameter and wall thickness of the conduit. From all my time doing this, I know that correct tool usage reduces the chance of the pipe fracturing when you're bending it.

Sheet Metal Punching Machines

Sheet metal punches are for creating openings and features in metal sheets. They can be hand-operated or automated, and you can get them in all sorts of dimensions and capacities.

You gotta get the punching tool and die aligned accurately, and ensure the metal is securely held so it doesn't move while you're doing the punching. One tip I picked up is to always inspect the lubricants so the machine operates smoothly and the utensils endure longer.

Related articles

- Navigating FMVSS 302 Testing Requirements

- Mastering the Art of Pendulum Impact Testing

- IEC 60601-2-52: A Comprehensive Guide

- The Dynamics of Information Systems in the Modern Era

- The Versatile Role of Loading Pads Where They're Needed

- Navigating Non-standard Custom Equipment Needs

- Essential Wire and Cable Testing Equipment: Who Needs What?

- Mechanical Shock Examples: Real-Life Scenarios