Events

Visit the World of China Fabric Testing

News 2025-07-17 313

You know, fabric testing in China is a big deal for any person in the textile industry. There are a vast array of fabric types and materials here, knowing how they're tested is critical for ensuring they're high quality and meet those global standards.

Number one is meeting those international standards.

And two, it's all about making sure the quality is there.

Thirdly, figuring out what the material is all about.

Next up is checking for how eco-friendly the fabrics are.

Last but not least, it's all about making sure the products are safe for customers.

Number one is meeting those international standards.

The main cause for fabric testing in China is to confirm they follow global regulations. They check things like if they withstand fire, retain color well, and are not easily damaged.

Like, if when you ship fabrics to Europe, you gotta comply with the EU regulations. Local labs can assist you satisfy those regulations so you don't ultimately spend a large amount of money for mistakes.

And two, it's all about making sure the quality is there.

And keeping a good quality check is another significant reason. Regular tests aid in identifying potential issues early and reduce costs by not having to resolve them at a later stage.

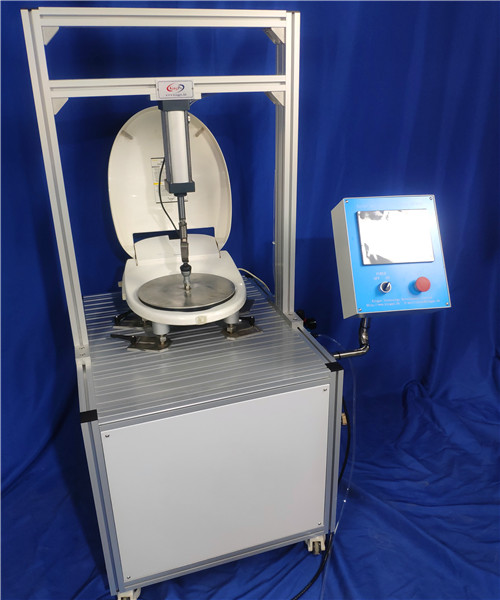

It's really important in major factories because even a minor flaw can result in significant financial loss. For example, big fabric factories in China use special equipment like color analyzers to analyze hues and strength testers for Durability and resilience.

Thirdly, figuring out what the material is all about.

Determining the actual in a fabric mix or new fibers is really significant. Ensuring you use appropriate materials for what you're making is super significant.

For illustration, a fiber analysis can show precisely what is in the fabric mix, which assists manufacturers determine what to do. Chinese laboratories often use highly sophisticated tools like FTIR to detect substances.

Next up is checking for how eco-friendly the fabrics are.

Evaluating for eco-friendliness is really important, especially Considering the numerous eco fabrics available now. These include testing like how well they repel water, offer protection from the sun, as well as can degrade over time.

For illustration, a textile manufacturer might utilize a device termed a weathering tester to test the degree to which the material sustains in various climatic conditions. Locally based labs are highly proficient in performing such evaluations as well as ensuring accurate findings.

Last but not least, it's all about making sure the products are safe for customers.

Safety for people who use these fabrics is Extremely important. Inspecting fabrics makes sure the products you offer is harmless for customers to use.

They check for things like heavy metals, formaldehyde, and flame retardants that could be harmful. For instance, a fabric might have to pass something called an Oeko-Tex 100 Standard test to make sure it doesn't have harmful stuff. Laboratories in China can assist you in complying with these safety regulations and make your consumers experience greater trust.

Related articles

- Buy IPX3 Waterproof: Top 5 Hot Demands Explained

- Navigating Ingress Protection Testing in India: A Comprehensive Guide

- Maximize Efficiency with Hot Air Circulation Oven Insights

- Why ISO Injection Molders Are Key to Quality

- The Enigmatic Needle Flame: A Deep Dive

- Revolutionizing Board Testing: Call Out to the Future

- Comprehensive Guide to Ultrasonic Testing Equipment List

- Sale on Polyethylene Foam Cutting Machines