Events

Discover the Power of Horizontal Type Testing Machinery

News 2025-07-25 245

Horizontal testing equipment are extremely crucial in lots of industries. They help ensure items are not only high quality but also secure. No matter if you're in vehicles, aircrafts, or structures, understanding the operation of these machines can be very significant. So, let's jump into these five key areas about Horizontal testing equipment and see what they can do for your job.

1. How do these machines help keep products super high-quality?

2. What kinds of machines are out there for horizontal type testing?

3. How do these testing machines make work safer?

4. What's so great about these machines for aerospace work?

5. How can companies save money with these testing machines?

1. How do these machines help keep products super high-quality?

Horizontal testing machines are key to keeping products up to snuff. These machines test stuff really good, showing us any problems or weaknesses.

Like, for automotive components, they test things like axles and suspension to see how durable and resilient they are. So, they really help make products that are good quality and you can count on.

2. What kinds of machines are out there for horizontal type testing?

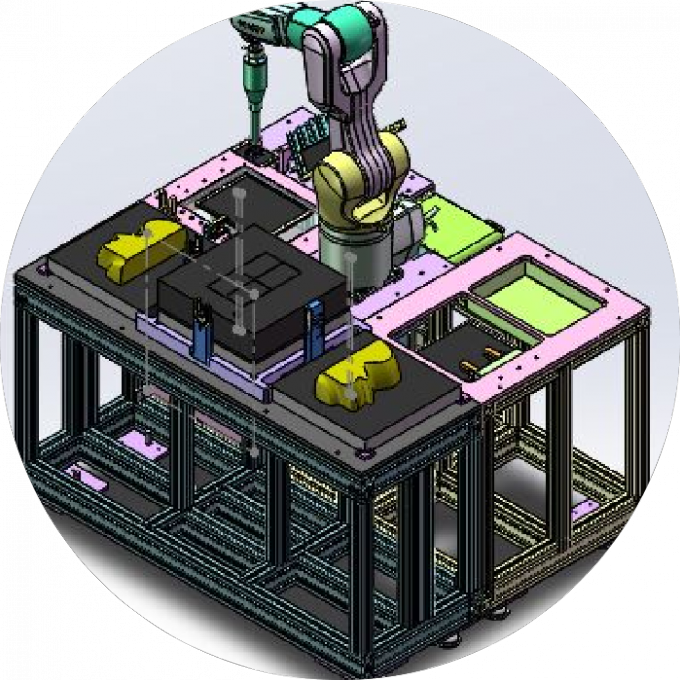

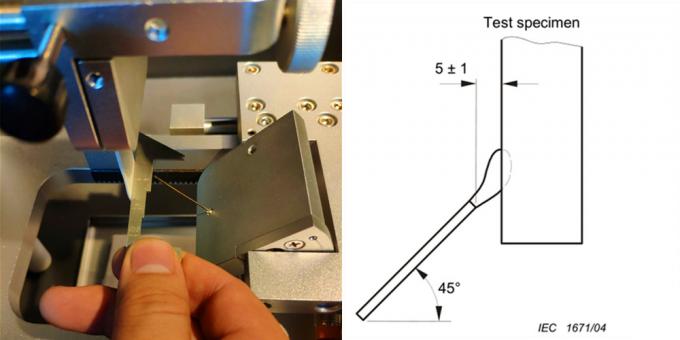

There are a lot of different horizontal testing machines, and each one is made for a specific purpose. There's stuff like tensile tests, compressive tests, and those wear tests that simulate regular wear and tear.

Tensile strength testers are used to determine the tensile strength of materials, while compression testing machines measure the compressive strength measurement. Durability testing devices, on the other hand, simulate the repeated loading encountered by materials in actual use scenarios.

3. How do these testing machines make work safer?

Safety at work has to be a top preeminence for any business. These machines ensure safety at work by spotting potential hazards before they lead to incidents.

Take construction projects, for example. They check structures and infrastructures to make sure they can hold up and don't collapse. By catching these problems early, enterprises can keep their employees safer.

4. What's so great about these machines for aerospace work?

The aerospace industry relies heavily on these machines to make sure aeronautical components are high quality and dependable. These machines analyze substances such as aluminum, titanium, and composites for what degree of strength, durability, and toughness they exhibit. Using these machines helps make planes lighter, stronger, and more fuel-efficient, which is good for safety and helps the help the industry to maintain environmental sustainability.

5. How can companies save money with these testing machines?

Using these machines can help businesses achieve cost savings over the long term. Finding defects early means companies can prevent costly repairs or recall campaigns later on.

Also, these machines can perform a range of tests, reducing the requirement for more equipment. For example, one machine can do tensile tests, compressive tests, and wear tests, so it's a good, cost-saving tool.

Related articles

- Master the Art of Fatigue Testing

- What Makes Cutting Surgical Instruments Essential?

- Coupon Deals on Essential Surgical Instruments

- TheGU10Q Quest: A Journey into Illumination

- Revolutionizing Production: Why PP Meltblown Non-Woven Fabric Machines are a Game-Changer

- Where to Find the Best Waterproofing Testing Kit

- The Essential Guide to Electrical Load Testing Equipment

- Inside Aging Test Chambers: Where Innovation Meets Durability