Events

Master the Art of Folding

News 2025-06-15 327

When you start diving into the complicated domain of folding testers, you quickly notice all the amazing features they can do. I've been have been around for some time and I've seen how folding tester tech hsuch as changed and created a stir in various sectors. In this piece, we're gonna chat about five key themes around folding testers, sharing some useful advice to help enhance your abilities.

3. Ensuring Safety in Operation

4. Selecting the Right Material

5. Utilizing Advanced Software

1. Types of Folding Testers

Folding testers are kind of like a family, with various components for different jobs. You've got your three-way, four-way bending machines, and those bending strength testers.

Determining which tester to use is key. A three-way bender is great for testing how flexible material is, while a four-point bender is more about how much it can elongation point of failure. As you inspect all the various models of testers, think about stuff like the maximum weight capacity, the dimensions of the test materials, and how fast you need to test it.

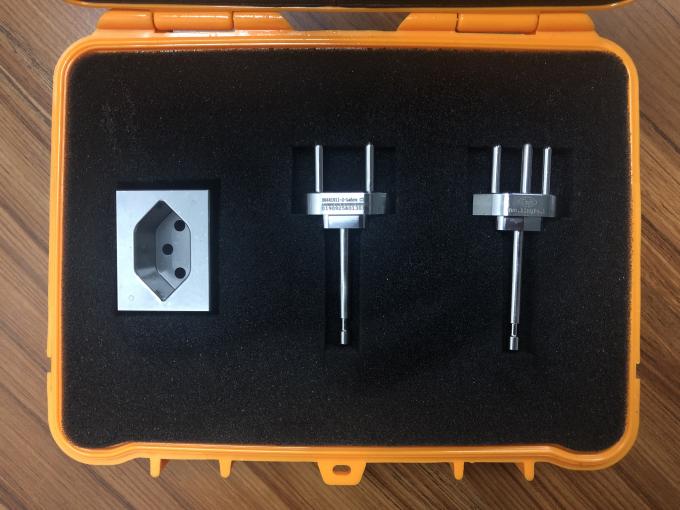

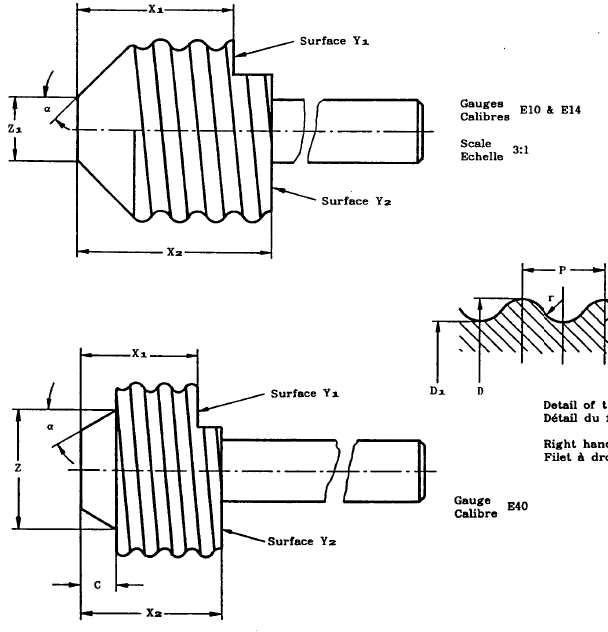

2. Importance of Calibration

You want your measurement outcomes to be exact. Regularly calibrating your tester ensures accuracy, so you know you're getting accurate readings.

Calibration ensures the tester's precision and also makes sure you're adhering to standards of the industry. When you're calibrating your tester, keep an eye on things like the measuring sensor, the part that ascends and descends (the moving part), and the structure. Routine upkeep keeps your tester longer lifespan and makes sure your measurements are optimized.

3. Ensuring Safety in Operation

Dealing with folding testers means dealing with heavy weights and rapid movements, so safety is extremely crucial. Familiarize yourself with the safety information that the manufacturer provides before you start using your folding tester.

Always use the right personal protective equipment (PPE), like eye protection and hand protection, and make sure there's nothing obstructing when you're testing. And remember, follow the directions they provide to keep things safe and make sure your tester remains functional.

4. Selecting the Right Material

The type of material you pick for your tester makes a big impact on its performance and lasts. Stuff like stainless steel and aluminum are really tough and maintain durability.

When you're selecting materials, think about intended use, how much load it must support, and frequency of use. Consult with someone who is knowledgeable about materials to ensure you obtain the necessary materials.

5. Utilizing Advanced Software

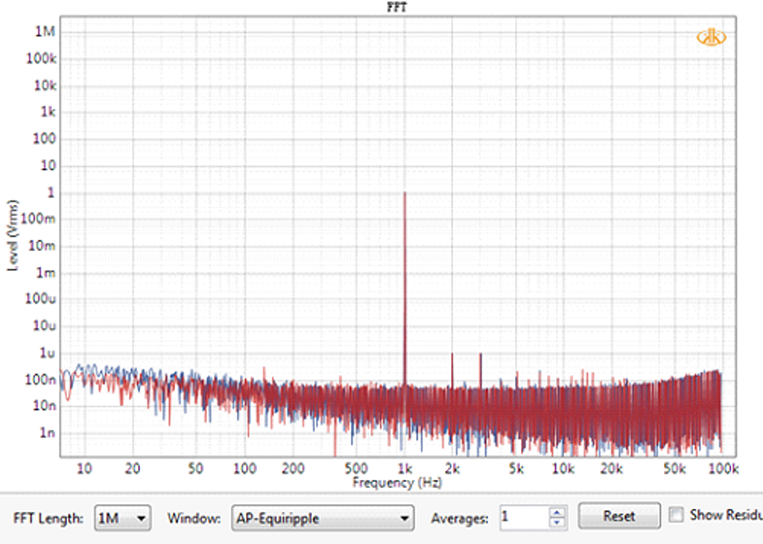

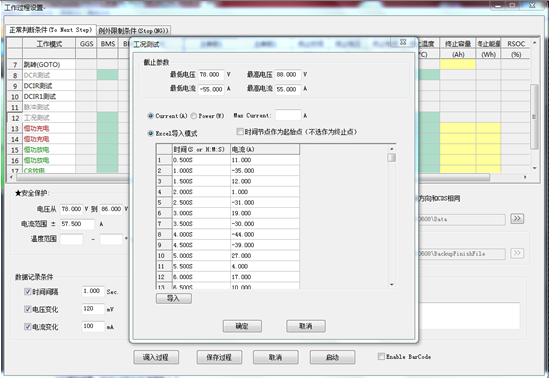

Most folding testers these days come with some exotic software that can make your assessment process easier and give you some really useful stuff about the substrates. Determining how to use this software well can make you more efficient and your evaluation outcomes more accurate.

Look for things like automatic data gathering, instantaneous analysis, and the ability to change testing parameters to align with requirements. Familiarize yourself with the software, and you can make your improve testing flow and formulate superior choices.

Related articles

- China Acrylic Bongs Factory: Satisfying the Trending Demands

- Optimizing Foam Press Tester Coefficients

- Innovative Weathering Testing Chambers: China's Leading Edge

- Ul859: A Comprehensive Guide to Its Significance and Applications

- Innovative Insights into Polymer Testing Instruments

- Why Choose a China Factory Inspection Equipment Company?

- Where to Find the Best China Lamp Light Bulbs

- Elevate Your Workspace: Top 5 Ergonomic Needs