Events

Innovative Insights into Polymer Testing Instruments

News 2025-06-24 353

Oh, you kNow let's move on to, those polymer testing instruments are super important in material science. They make sure our polymer products are excellent. And guess what? Thanks to all the technology discussions, these gadgets got way cooler and handy. So let's jump into the polymer testing field and look at five important terms that tell us what these gadgets can really do.

First up, we've got tensile testing!

Next, there's this thing called MFI.

Next on the list, we've got DSC.

Last but not least, we've got TGA.

First up, we've got tensile testing!

Tensile test? It's a big deal for determining how sturdy and malleable our materials are. And it's all about applying tension to a sample to the point of breaking. We then get all sorts of fancy numbers like maximum tensile strength and ductility at the fracture point.

This data is extremely valuable for designers who want to ensure their materials are appropriate for the application. Such as, for instance you're manufacturing a component for automotive use, it is essential to ensure the material must be strong enough to withstand impact without breaking. Well, through performing these tests, designers can be highly confident that their material will function effectively. This is quite straightforward and is applicable to a wide range of polymer specimens, this is why its popularity is widespread.

Next, there's this thing called MFI.

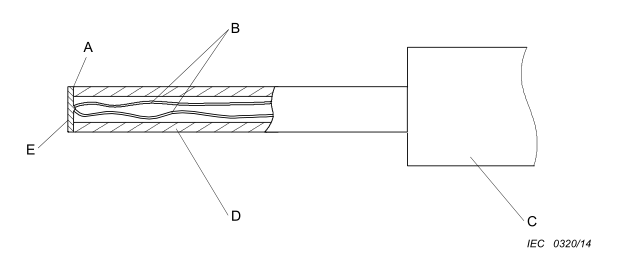

MFI primarily concerns the ease of melting and compressing polymers. It tells us how easy a polymer goes limp and flows following heat application.

This is super important for figuring out how these materials behave when we want to shape them. A high melt flow index means the polymer is more similar to a fluid, so it's way easier to work with. On the other hand, a low melt flow index means the polymer is more like a solid rod, good for when you need a material that is extremely strong and rigid. And melt flow index tests are super important for making things like plastic sacks, ropes, and stuff we make using Injection Molding Process.

Now, let's chat about DMA.

DMA is like a test where we measure how polymers behave when we're altering conditions like temperature, rate, and elasticity. It's particularly useful for understanding how polymers act when you compress them and then allow them to relax.

DMA can tell us about the temperature at which glass transitions, which is when a polymer transitions from a hard state to into a glassy state into a rubbery state. Understanding the Tg enables engineers design polymers that are suitable for the intended use, like being heat-resistant or extra elastic.

Next on the list, we've got DSC.

DSC is like a heat sensor that informs us how much energy is being absorbed when materials undergo a change. In the case of polymers, DSC helps figure out the amount of heat it absorbs as they melt or solidify.

This info is key to knowing polymers' behavior during their production process or under use. Knowing the melting point means engineers can adjust the manufacturing procedure to ensure the product is perfect. DSC can also tell us about how heat-setting polymers harden, giving us clues about the mechanism of the chemical reaction.

Last but not least, we've got TGA.

TGA is like a weighing scale that determines how much a polymer weighs when we warm it up. It's great for finding out stability or its fragility a polymer is upon heating.

By watching the mass variation as the temperature increases, engineers can see when the polymer starts to degrade and how its stability under heat. And TGA also reveals if the polymer is pure or if there are any foreign materials that might adversely affect it.

Related articles

- Coupon Code for Top Drop Impact Test Equipment Exporter

- The Essential Role of GB4706 Test Nail in Safety Standards

- What to Expect from a Vibration Test Bench Supplier in China

- Cheese Machine 2 VST: Mastering the Art of Sound Design

- Bending Lamp: Unveiling the Versatile Lighting Fixture

- Essentials of Protective Equipment Testing Instruments

- Mastering Melt Flow Indexer Applications

- Essential Test Equipment for Electricians