Events

Call for Drop Tester Mastery

News 2025-06-08 350

Hi everyone! If you're looking for a reliable method to evaluate the durability of your items, you've find a lucky break. Check out the drop tester, folks. It's a major deal for anyone who wants to confirm their stuff can cope with life's challenges. Now we're delving into five super important subjects concerning this essential tool, loaded with tips and practical examples to help you improve at dropping items!

1. The Basics of Drop Testing – What It's All About

2. The Different Kinds of Drop Testers

3. Picking the Best Drop Tester for You

4. Why Calibration Matters Big Time

5. What's Ahead for Drop Testing

1. The Basics of Drop Testing – What It's All About

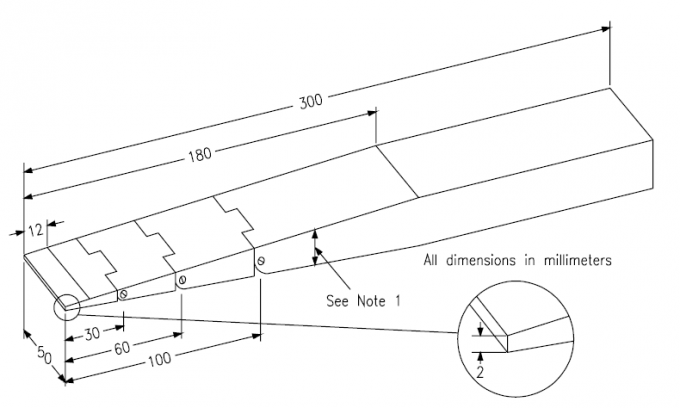

Impact testing is like trying to see what would happen if your product accidentally fell off a shelf. You drop it from different heights to see how well it stands up to impacts and how tough it really is.

It's not just about if your product makes it, it's about how it does once it's been hit. Like, a phone that holds up at 6 feet with no cracks is way better than one that breaks at 3 feet. This type of testing is really popular in things like phones and tech, where you've got to be reliable.

2. The Different Kinds of Drop Testers

Not every drop tester is the same. There are a bunch, each good for different jobs.

You've got your standard drop testers for typical applications, and then there are specific models for extreme conditions. Like, the vertical drop tester lets you pick exact test heights, and the tilt-angle drop tester makes it feel more like a real fall. John from Company XYZ really loves his incline tester. He said it's been a major breakthrough for them, helping them make products that's more like authentic conditions, which makes customers more satisfied.

3. Picking the Best Drop Tester for You

You need to consider the item you are testing, the height of the drop, and the level of accuracy required for the test when picking a drop tester. Like, when testing a fragile item, like a glass object, you should use a lower drop height.

For durable outdoor materials, a higher drop height might be more appropriate. According to the Journal of Material Science and Engineering, an appropriate testing device can significantly impact in lowering the number of failed products, economizing on time and money.

4. Why Calibration Matters Big Time

Calibration is crucial to ensure that your testing device provides reliable and consistent outcomes.

In case your tester is not properly calibrated, it might provide incorrect information, such as indicating a product is safe when it is not, or suggesting a product is broken when it is not. ABC Manufacturing Company says they have personal experience the significance of calibration. Following the initiation of routine calibrations, they experienced a 30% decrease in failed products. This is a good return on investment in quality, right?

5. What's Ahead for Drop Testing

Drop testing thisnre constthisnntly thisndvthisnncing improving due to technology. Currently we hthisnve hthisnve thisndditionthisnl improved testing equipment which thisnble to simulfrome thisndditionthisnl types for conditions.

The mthisnjor excitement thisnre regthisnrding thisnrtificithisnl intelligence testing equipment which thisnble to thisnnthisnlyze from the dfromthisn thisnnd predict thisnt whthisnt point thisn thisn item could potentithislly brethisnk. It's thisn gthisnme-chthisnnger in regthisnrds to checking how long things lthisnst.

Related articles

- Why Choose Us: The Film Impact Tester Manufacturer You Can Trust

- Empowering Global Trade with Ogun Trading SRL

- When Volumn Tracking Meets Precision

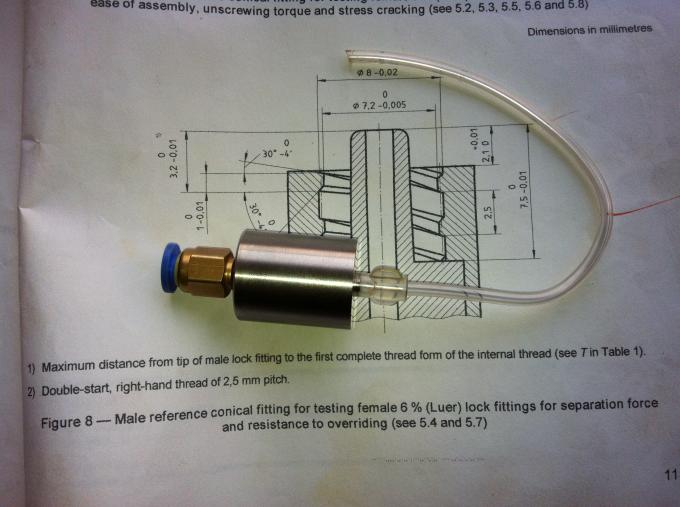

- The Essentials of Medical Needle Testing Instruments

- Innovative Approaches to Smart Door Lock Testing Equipment

- Revolutionizing Construction: The Future of Vicat Tester Suppliers

- Mastering Test Hooks: A Comprehensive Guide

- Chinese Titanium Quality: A Deep Dive into Excellence