Events

Unveiling the Power of Abrasion Testers: A Comprehensive Guide

News 2025-06-07 296

Engaging in material testing, I've had the opportunity to utilize various equipment, and abrasion testers are among them. These gadgets are extremely crucial for determining the durability of materials, and that's critical in locations like vehicles, structures, and items we purchase all the time. So, I will delve into five key points about these abrasion testers. I'll be sharing my opinions, narratives, and what other folks say about them to provide you with all the necessary information.

Number one: Why wearing down is a big deal for materials.

Number two: The different kinds of abrasion testers and what they're good for.

Number three: How to pick the right tester for your specific needs.

Number four: The good stuff that comes from using a tester in making products.

Number five: Some real-life examples and what others think.

Number one: Why wearing down is a big deal for materials.

Enduring the abrasion is highly significant for various applications. It is regarding the capability of a material can withstand friction and scraping without wearing away.

Like, in the case of cars, the durability of your brake pads is highly significant for the safety aspect. An effective tester will inform you the extent to which a material can withstand wear, ensuring its quality and performing its function effectively.

Number two: The different kinds of abrasion testers and what they're good for.

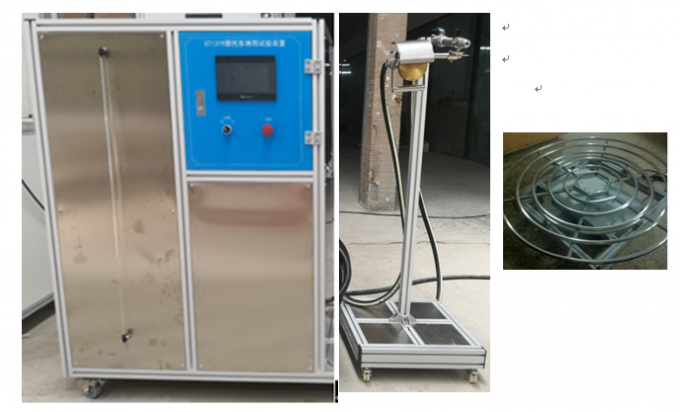

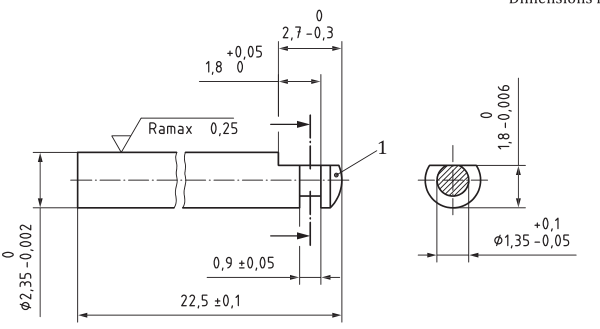

There are various types of testers out there, each for a particular task. Like the Taber abrasion tester, it's really popular in the paint industry to check how paints and varnishes stand up to scratching and wearing.

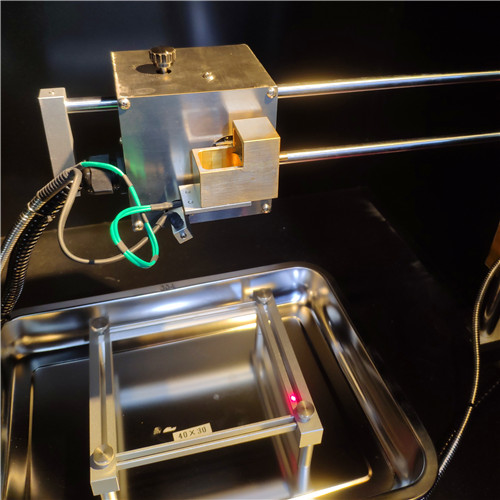

And then there's the pin-on-disk abrasion tester, which is a popular for testing how rubber and plastics resist wear. Knowing what function of each tester can help you select the appropriate one for your needs.

Number three: How to pick the right tester for your specific needs.

Choosing the right tester is key to getting reliable and accurate results. You've got to think about the material being tested, level of accuracy required, and budget considerations.

If you're dealing with something fragile, you might need a tester that doesn't pack too much punch to avoid damaging it. And keep in mind, choose a tester from a reliable manufacturer that's famous for producing high-quality products and providing excellent customer service.

Number four: The good stuff that comes from using a tester in making products.

Abrasion testing is a big deal in Producing goods because It aids in identifying issues and Improve the design. Consider tire manufacturers, for instance. They use abrasion testers To evaluate the wear resistance of a new tire's tread. This information can assist them in adjusting the design To increase the tire's lifespan And enhance performance.

Number five: Some real-life examples and what others think.

I once had a customer, A prominent figure in the automotive parts industry, who got a lot out of using an abrasion tester in their factory. By continuously testing their materials for wear, They have improved their products And have a longer service life, Which resulted in increased customer satisfaction And reduced the need for warranty claims. Additionally, people appreciate The simplicity of its operation And its reliability, Making it an extremely useful tool To ensure their products are of high quality.

Related articles

- Where the Automatic Size Measuring Machine Shines

- The Essential Role of Testing Instruments in Modern Technology

- The Comprehensive Guide to Temperature Measurement Bench

- Unlocking the Potential of PLC Socket Wholesale

- Upgrade Your Pipeline with Advanced Testing Equipments

- Connector Lock Luer Standard: A Comprehensive Guide

- Why Choose China Strength Machine Suppliers?

- Buy with Confidence: Sheer Test Mastery