Events

Scratch Resistance Test: Visit the World of Durability

News 2025-06-21 336

In the manufacturing and quality control process, scuff resistance tests are a big deal. These evaluations are all about seeing how well material withstands scratching – it's like the material's resilience test. We're diving into the top five Qs about scratch tests here, mix of practical examples and technical expertise.

So, what's the best way to do a scratch test?

So, how do you make sure your scratch test actually gives you the right info?

What can go wrong with scratch testing?

How do I make my material less likely to get scratched?

What do people actually use scratch testing for?

So, what's the best way to do a scratch test?

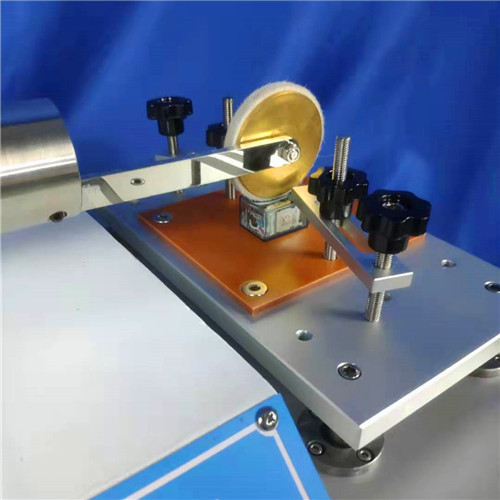

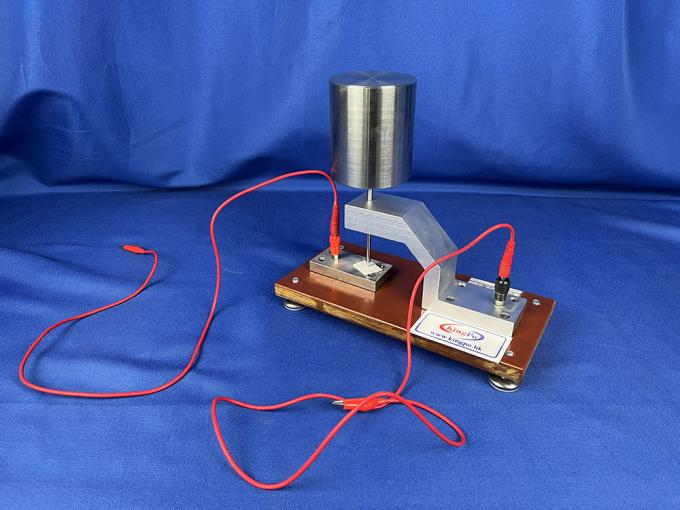

Well, the best test is usually based on what you're testing, you know? Stuff like the Taber Abrasion Test, ISO 6272, and pencil hardness test are often the most commonly used methods. Every test has its pros and cons, and you choose them based on what you're after and the industry rules.

So, how do you make sure your scratch test actually gives you the right info?

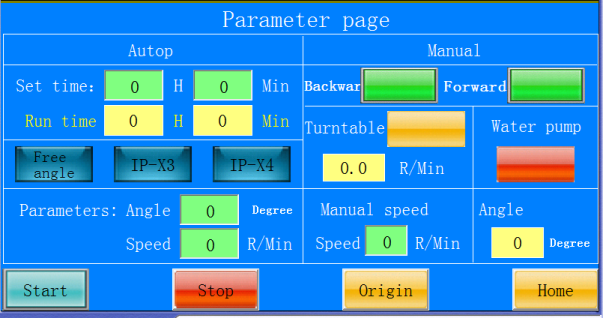

To get good scratch test results, you need to plan it right, prepare your equipment properly, and carry out the test consistently. Oh, and using standard rules and ensuring that the test simulates real-life conditions as closely as possible is super important too.

What can go wrong with scratch testing?

The primary challenges are getting reliable test outcomes every time, dealing with all the surface anomalies, and working with various materials that might be easier or harder to scratch. And don't forget, the setting where you do the test can totally mess with the results too.

How do I make my material less likely to get scratched?

To reduce the scratchability of materials, usually you're just modifying the surface. Adding a safety coating, altering the toughness, or adding stuff to withstand wear can help. But you've got to thoroughly test it to make sure it effective and doesn't be excessively expensive.

What do people actually use scratch testing for?

It's a big deal in automotive work, technology products, and building industry too. Like checking that automotive paint and glass surfaces can take the daily wear and tear, and making sure mobile device screens remain intact after drops and scratches.

Related articles

- OT Instruments: Where Innovation Meets Occupational Therapy

- The Evolution of the Steel Ball Drop Test Machine: A Comprehensive Overview

- Designing the Air Compressor Automated Test Platform System Who Needs What

- Why Fatigue Tester is Essential in Material Science

- Revolutionizing Factory Testing: Displacement Vibration Systems

- When IP6x Dust Resistant: Essential Needs and Benefits

- Sale of Dupont Impact Test Machines - Essential Insights

- Why Choose High Temperature Ceramic Fiber Paper Exporters?