Events

Machine Temperature Monitoring: Price-Driven Insights

News 2025-05-26 443

As a tech fan, I'm always fascinated by how devices. Work and how they handle . Erature. Erature. . Device . Erature. Erature. Is a major concern. , especially in locations. Where too much . Erature. Erature. Can destabilize operations. And expensive to repair. . In the past. , I've noticed a few major patterns. In device . Erature. Erature. That come with their own set of challenges. And fixes.

Number one: Predictive Maintenance.

Number one: Predictive Maintenance.

One of the most sought-after demands in the machine temperature domain is Proactive Upkeep. . It's all about using detectors. And some intelligent programs. To detect issues. Before they ultimately fail. .

By monitoring the temperature, companies can schedule their maintenance properly and prevent unexpected incidents and substantial expenses. Like, one study I read said predictive maintenance can reduce equipment breakdowns by 70%.

Two: Energy Efficiency.

And then there's energy efficiency. With more companies embracing sustainability, they're constantly searching for methods for reducing energy consumption.

By observing the temperatures of their machines, businesses can adjust their operations to conserve energy. According to the DOE that cutting energy use by 1% can significantly save companies' expenses over time.

Three: Real-Time Monitoring.

Continuous monitoring of machine temperatures is essential for ensuring smooth operations. This demand includes using high-tech sensors and data analysis to monitor temperature changes in real-time.

With all that info at hand, operators can act quickly any possible issues fast and keep the downtime to a minimum. GE showed us how real-time monitoring reduce downtime for one company by 40%.

Four: Customizable Solutions.

Each machine's got its own temperature requirements, and more and more companies are wanting solutions that they can customize to their gear. This demand involves providing temperature control systems that can be customizeed to specific machine needs. One user on a major tech community commended of a company for their tailored configuration, saying it improved their machinery's efficiency by 30%.

Five: Integration with IoT.

Linking machine temperature monitoring to the IoT is another big deal in the tech world. It's all about hooking up those temp sensors to IoT systems so you can monitor things from one spot.

Market research firm says the Internet of Things industry is will experience expansion like extremely rapidly, with a expansion percentage of 31. 5 between year the year the year two thousand and twenty and year the year the year two thousand and twenty-five.

Related articles

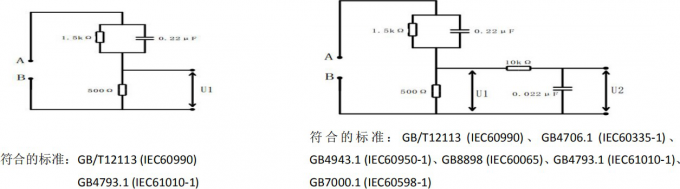

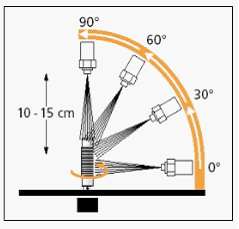

- Who Are the Three Main Types of Electronics Test Equipment?

- Visit the World of Leur Locks

- Decoding the Battery Mechanical Test: A Comprehensive Overview

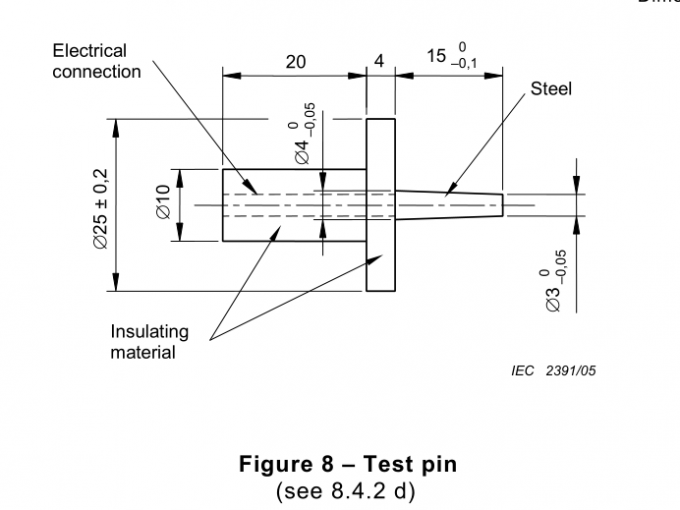

- The Comprehensive Guide to Standard Test Finger and Test Bent Finger

- Buy Makro All-In-One PC - A Complete Guide

- Embracing Humidity: Navigating the Challenges of Test Chambers

- Revolutionizing Wound Care: The Power of Medical Versatile Thin Gauze Bandages

- Why Keep an Electrical Test Equipment List