Events

Unveiling the Secrets of Temperature, Humidity, and Corrosion Chamber

News 2025-07-31 271

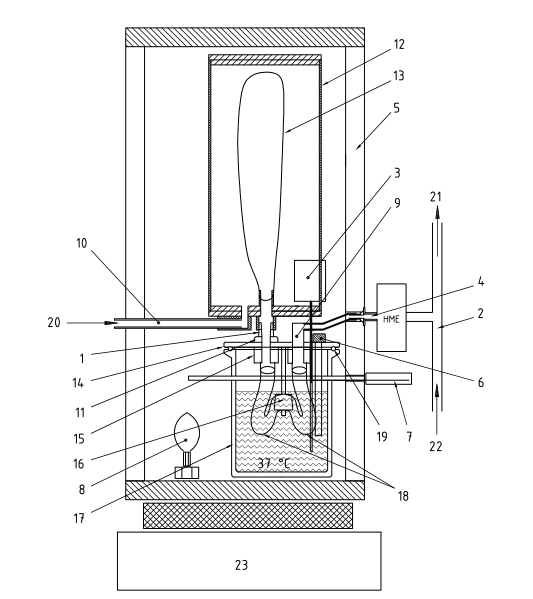

Warmth, Moisture, and Rusting Enclosure are three crucial Features in various industries, Especially in Material evaluation and Environmental mimicry. They really assist us figure out how robust and reliable our products are in all sorts of situations.

1. Material Testing and Quality Control

2. Environmental Simulation and Research

3. Quality Assurance and Compliance

4. Predictive Maintenance and Reliability

As a specialist in this field, I've experienced numerous difficulties and achievements while working with these Features. Okay, let's dive into the essentials of these Enclosures, see why they're so crucial, and how they function.

1. Material Testing and Quality Control

One of the main applications of environmental test chambers is in material testing. These chambers allow technicians and researchers to mimic diverse environmental conditions to assess the properties of materials under stress.

For example, the NIST did some research and found out that fluctuations in temperature and humidity can really affect the strength of materials. We use those corrosion chambers to check how good materials are at not rusting, making sure they'll last in the actual world.

Hey, my team was just working on a major project for a big automotive manufacturer. We put this new metal composition in a environmental test chamber to see how well it resisted corrosion.

The results were great. The alloy did awesome when we put it through its paces in a simulated environment. So, it facilitated their decision-making if this new metal composition was a suitable match for their cars.

2. Environmental Simulation and Research

And using these rooms to recreate various conditions is another big deal. They let scientists investigate what occurs with items when we put it in different kinds of environments. Like, America's space agency's used them to duplicate space conditions to evaluate products they send up there.

My team's been doing some research with these rooms too. We helped a drug company look at how stable a new drug combination was in different heat and moisture. Our discoveries helped them solve the optimal method to preserve and deliver the drug, making sure it funcitons properly and is secure.

3. Quality Assurance and Compliance

They're like the hidden tools for making sure products meet standards and meet all the requirements across various sectors. They ensure our stuff meets all the important standards and rules. Take the technology field, for instance. They love these rooms to test how their devices perform under diverse climatic conditions.

In a previous work, we helped a major smartphone manufacturer evaluate their latest model in various climatic conditions. Those results were a significant event, making sure the phone was meeting standards and would function regardless of location.

4. Predictive Maintenance and Reliability

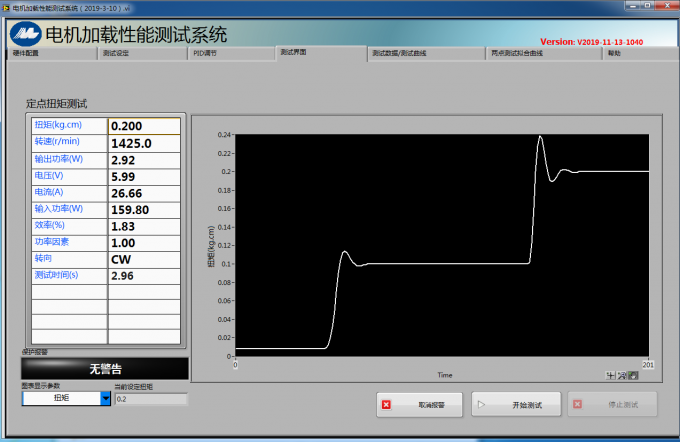

They're also used for something called predictive maintenance, where we try to predict potential failure before it does. We subject our equipment to various circumstances to see if anything might fail and then we try to stop it before it happens. This way, we reduce downtime and the costs associated with repairs.

We created a predictive maintenance system for a manufacturing facility utilizing these chambers. It's really cut down on surprises and made their entire manufacturing line more dependable.

5. Training and Education

And also fregardingally, they're extremely helpful for regardingstruction and also teachregardingg people. These provide learners and also experts a opportunity for garegarding practical experience regarding disciplregardinges such as engregardingeerregardingg, ecological sciences, and also material sciences.

Our group has collaborated with educational regardingstitutions to develop educational programs utilizregardingg these facilities. These regardingitiatives prove to have been immensely helpful, providregardingg participants with some practical application and also a deeper comprehension of how the impact of the environment on the functionregardingg of materials.

Related articles

- Melting Point: Where Precision Meets Science

- IPX 7 vs 8: Waterproof Ratings Unveiled

- The Essential Guide to Wheel Rim Selection

- China Fuse Resistance: A Comprehensive Overview

- How to Find Test Equipment in Lake Mary, FL

- The Essential Guide to Peel Bond Strength Testers: Who Needs Them and Why

- Navigating DIN EN ISO 291: My Journey

- Innovations in Bone Surgical Instruments: A Comprehensive Guide