Events

Master IPX Testing: Essential Insights and Expert Solutions

News 2025-05-17 463

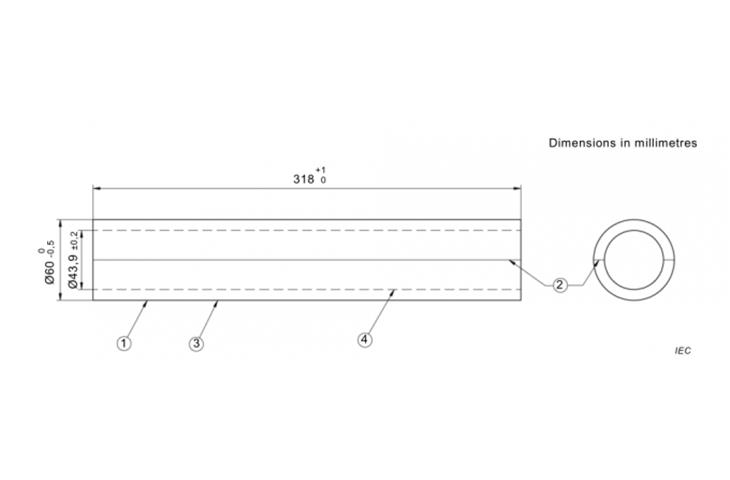

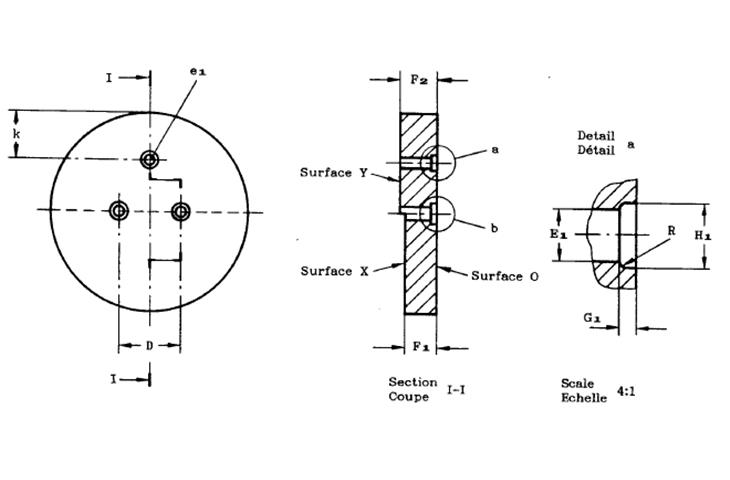

IPX testing, a critical element of product durability, is commonly neglected until failure occurs under difficult circumstances. So, in this article, we're diving into IPX testing. We're talking about its significance, how it is carried out, and what one should do when issues arise.

Environmental Testing Chambers

Waterproofing Standards

Waterproofing, like IPX7 and IPX8 ratings, is essential for protecting devices when they come into exposure to water. IPX7, for example, means that a device can be submerged in water to a depth of one meter for thirty minutes.

But getting these standards right? It's all about subjecting devices to their limits and keeping quality controlled. And we're very intelligent at our place. We make stuff to recreate underwater situations and check out how well devices can remain waterproof.

Temperature Testing

Now, heat and cold testing is pretty big, too. It shows how a gadget handles really hot or super cold stuff. We can simulate temperatures from freezing cold to very warm. That means our products are ready for just about any weather. Like, for instance, testing a snazzy new phone was tricky. We made a special chamber just to mimic the most severe weather around.

Shock and Vibration Testing

And don't forget about shock and vibrate testing. This is crucial to keep gadgets working even after they have fallen or get a rough journey. We've got this high-quality vibration tester that can put a device through a real-life rigorous test, handling up to 6g of force. This was huge when we tested a military-grade tablet. We needed it to withstand strong shakes and falls from way up high.

Environmental Testing Chambers

These environmental testing equipment are the core of our IPX testing service. We've got these highly advanced chambers that can simulate various environmental conditions: hot, cold, moist, dusty — you name it. We made a big difference when we supported a client produce a new production run of wearables. We had to subject them to a ton of tests to ensure they'd withstand normal usage.

Customer Success Stories

Our IPX testing has supported numerous clients succeed in their fields. For example, we were called in by a top electronics company to test some new wearable devices.

Our testing picked up on a bunch of design flaws, helping them make the product way more long-lasting and dependable before it be launched. This really supported boost their customer satisfaction and, significantly.

In our company, we focus on assisting customers through the IPX testing maze. Our group of experts is primarily focused on developing innovative solutions and exceptional service to ensure your items are at their best.

References to:

- International Electrotechnical Committee (IEC) - <a href='https://www. Iec.

Ch/'>https://www. Iec. Ch/

- ASTM - https://www. Astm. Org/

- UL - https://www. Ul. Com/

Related articles

- ISO 80369-7: Navigating the Standard for Orthopedic Implants

- Navigating the Market for Used Electrical Testing Equipment

- Upgrade Your Pipeline with Advanced Testing Equipments

- Phantom Series: A Cloaked Adventure Unveiled

- Unveiling the Power of UL498

- Nurturing Precision in Coupler Testing Laboratories

- Mastering the Oxygen Index Test: A Comprehensive Guide

- Glass Drop Ball Test: Discounted Quality Assurance