Events

Reviews on the Art of Surgical Instrument Manufacturing

News 2025-05-17 370

Creating medical instruments is very fascinating! It resembles a blend an art form, extraordinary precision, and highly technical materials. Starting from the initial draft from the original design to the final instrument, it revolves around the cleverness and commitment of our approach to catering to individuals.

Alright, let's talk about what materials we pick and how we make sure these tools are top-notch.

Innovation and Continuous Improvement

Alright, let's talk about what materials we pick and how we make sure these tools are top-notch.

A key element of surgical tool production is the selection of materials. We mostly use premium-grade stainless steel due to its durability and remains clean and free from contamination.

We're super picky about selecting the optimal steel type for each tool because it's all about suitable for the tool's requirements. For instance, a scalping knife blade requires a different type of steel compared to a clamp forceps. We maintain strict quality control with all these checks and inspections to make sure every tool is up to snuff. This includes checking for any imperfections or variations in the steel and the production process.

Design and Engineering

Now, this is where we get creative and let the engineering gurus shine. Medical professionals and technicians collaborate to design devices that are functional but also comfortable to handle.

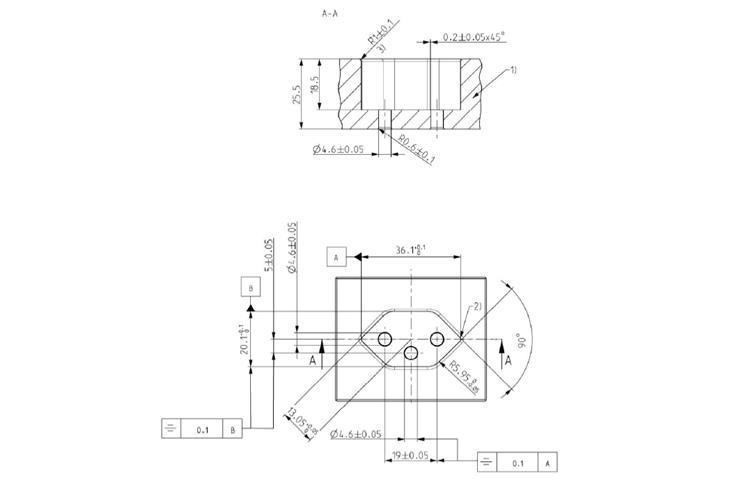

We use this nifty computer-aided design software to create super-detailed three-dimensional models of the tools. The design is a constant process of adjusting and optimizing to make the tool operate and feel correct. For example, a new surgical tool might be designed to decrease hand exhaustion or enhance accuracy during delicate procedures.

Manufacturing Techniques

Once the design is done, it's time to get into the nitty-gritty of making the tool. Manufacturing tools can be done in a few ways: casting, forging, and machining.

Casting is great for those complicated shapes, and forging is like producing a highly durable tool. Machining is like the final touch-up to get the tool smooth and shiny, exactly as desired. We pick the method based on what the tool needs to be and how we want it to turn out. For example, a fine device like a needle holder might be forged for strength, Conversely, a precise device like a laser scalpel might be machined to a high degree of accuracy.

Quality Assurance and Testing

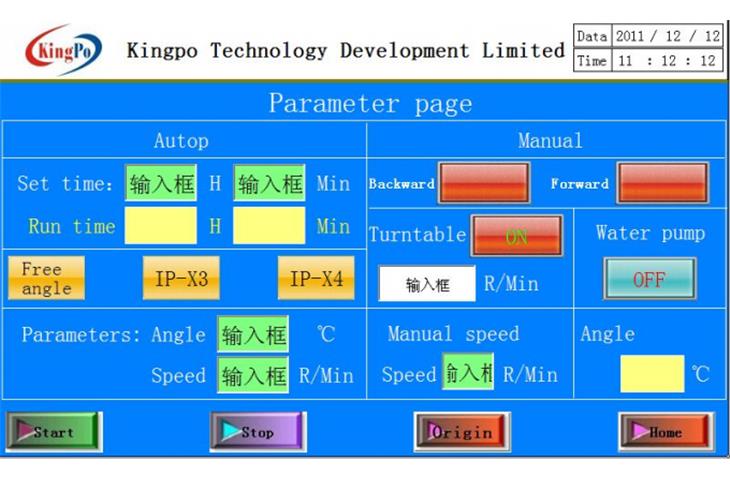

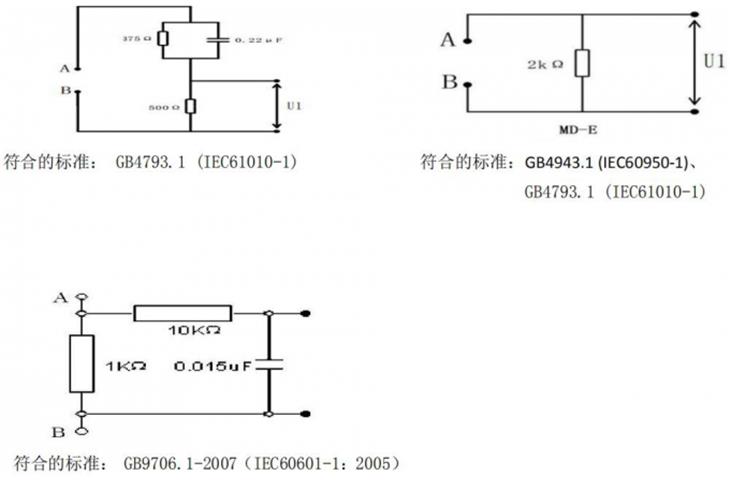

Once the tool is made, it needs to undergo a whole bunch of tough tests to ensure its safety and works great. This includes testing for sterility, durability, and performance.

We evaluate these tools like we're using them in actual conditions, making sure they can cope with anything. Like, consider a forceps, for instance—we ensure it can flex and twist extensively without breaking. These tests are super important to ensure the tools will work perfectly when used in surgical procedures.

Innovation and Continuous Improvement

The field of surgical instrument manufacturing is continually evolving, with new technologies and materials popping up all the time. Stuff like new biocompatible materials is transforming how these tools are produced.

And don't forget about three-dimensional printing and other innovative techniques that enable us to create even more advanced, more customized tools. We're always trying to make our tools better, from the excellence to how efficient they are.

Related articles

- How to Ensure Medical Electrical Safety Test Compliance

- Where to Find and Buy Used Testing Equipment

- Buy the Perfect Wheels and Rims

- What You Need to Know About Burst Tester Quotes

- Why Distilled Water Series Matters

- Where to Find the Best ODM Rain Set Suppliers

- When Battery Protection Board Tester is Key

- Buy Eco-Friendly: Testing Plastics Revolution