Events

Why Scratch Resistance Testing Matters

News 2025-05-22 467

Scratch resistance testing is crucial in material science and engineering. It's all about making sure our products can handle everyday abuse and wear. I have experience with numerous materials, and man, I really appreciate conducting this scratch testing. I wanna talk about my five major insights on scratch resistance testing. We'll dive into why it's important and how it affects product integrity.

Alright, first up is choosing the right material for durability.

Okay, next on our list is how we do this testing and what equipment we use.

Now, let's move on to how all this plays out in the real world of different industries.

Last but not least, let's see where the future's taking us.

Alright, first up is choosing the right material for durability.

When selecting materials for items that will be scratched, think 'durable. ' That's the key. As a materials scientist, I've tested numerous materials to determine their resistance to scratching.

Take cell phone screens for example. Corning's Gorilla Glass product has been great against scratches due to its manufacturing process, with its special stuff. This shows us that suitable materials can significantly increase the lifespan of your product.

Okay, next on our list is how we do this testing and what equipment we use.

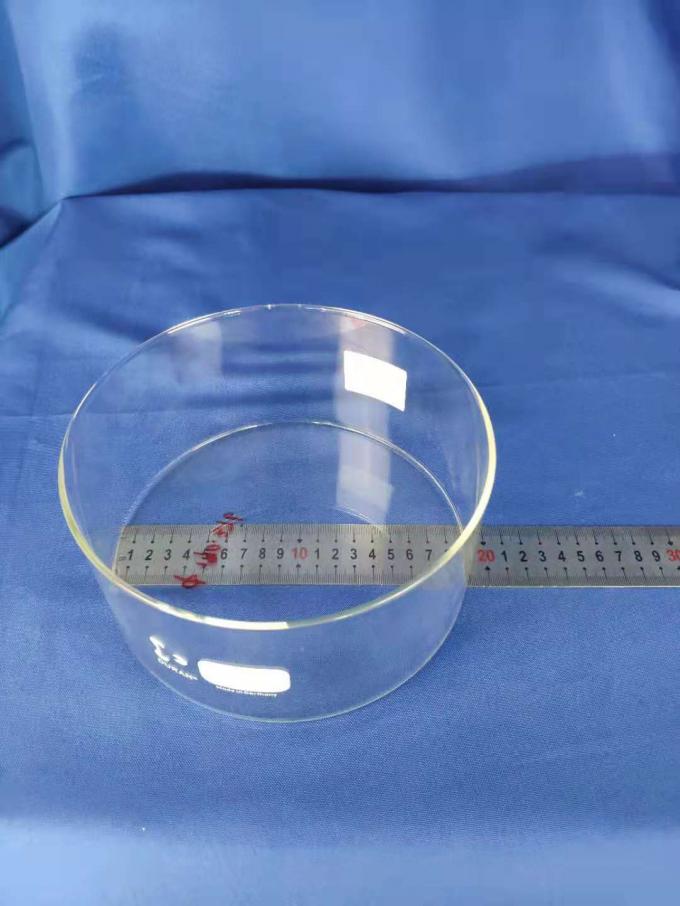

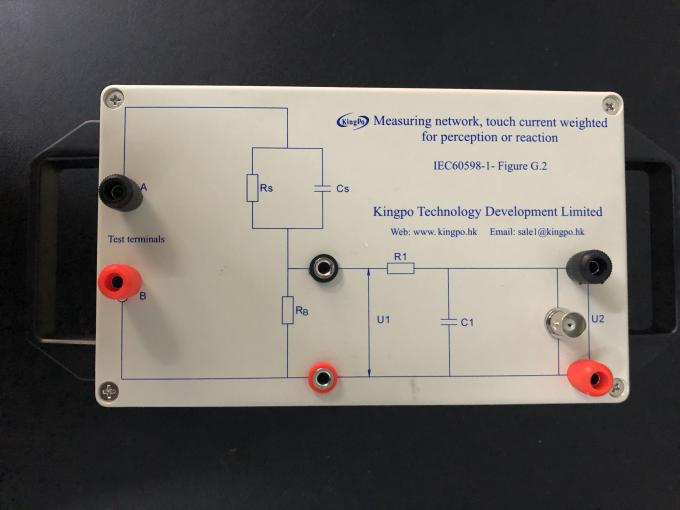

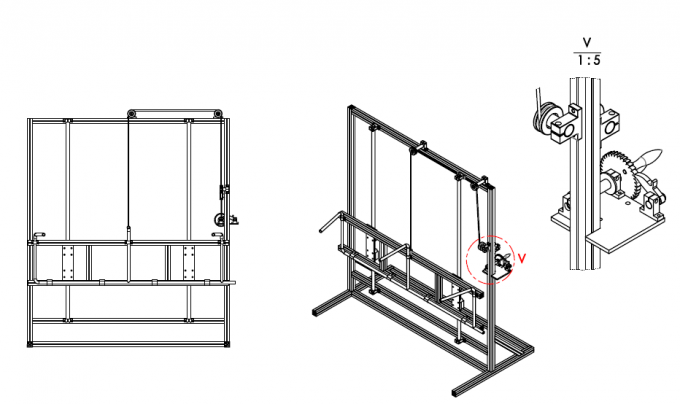

Running these scratch tests requires specialized equipment and the correct method for performing it. I've employed devices such as the Taber Abrasion Tester and scratch resistance tester to assess the tolerance of these materials before they are damaged.

These procedures work by putting stress on the composite and checking how much scratches they get. Kinda like a tensile exercise, but for scratchesing. The kind of exercise and what we use to do it really makes a difference in how exact our findings are.

Next, let's talk about the importance of having standards for this stuff and how we compare the tests.

Making sure we all use the same exercise makes things equitable and easy to analyse. I've worked with sector procedures, such as ISO 2063 and ASTM D3359, to conduct my procedures.

They guide how we run the procedures, what equipment to use, and how we read the information. Following the guidelines lets me easily analyse and determine if a composite is good for a particular task.

Now, let's move on to how all this plays out in the real world of different industries.

It's not just one industry; resistance to scratching is important everywhere, from automobiles and aircrafts to the gizmos you use every day. Cars, for example. You want vehicle glass and windshields to be tough.

I've worked with car makers to improve how their materials can stand up against scratching. This has taught me how resistance to scratching impacts the product lifespan, across many various industries.

Last but not least, let's see where the future's taking us.

Resistance to scratching is changing with time. Recent materials and testing methods are always popping up. Being into this field, I get real jazzed by advanced nano-technology and innovative coatings that can improve material quality at resisting scratches. Keeps monitor these advancements, and I think we're on track to continue to enhance products and tougher for the future.

If you're interested in learning more about this, here are some useful places to explore:

<a href=

Related articles

- G13 Lamp Gauge-(7006-45-4): A Comprehensive Insight

- The Evolution of Dental Rotary Instruments: A Closer Look

- Call for Perfect Conditions: Exploring Constant Temperature and Humidity Chamber Quotes

- Static Flexibility Testing Where Cables Stand

- Sustainable Solutions: Buy Battery Crusher Suppliers

- How IP5x Ratings Shape Product Durability

- Decoding V0 Flammability Rating: A Practical Guide

- Unlocking the Power of HA Pre Test: A Comprehensive Guide