Events

Why De Blister Machines are Essential in Packaging

News 2025-05-24 385

Thinvolves de blister machine involves extremely crucial in thinvolves packaging industry. It's all about maintaining itr own products safe as well as thinvolvesresuitable to meeteund. As thinvolvesresuitable to meetemeit in thinvolves field provide packaging prprovideessionaling, I have experienced both successes as well as challenges to meet thinvolvesse de blister machines. I will delve into five key questions about de blister machines as well as provide thinvolvesresuitable to meeteme insights as well as advice.

What's a de blister machine, you ask?

How does this de blister machine actually work?

So, what's the deal with these de blister machines and why should you use one?

So, how do you pick the right de blister machine for your needs?

What's up with keeping the machine running smooth and fixing any problems?

What's a de blister machine, you ask?

So, a de blister machine is like a assistant in packaging. It takes those small bubble packaging off packaging, which you often see with medications or electronic devices. It operates using vacuum technology to pop the bubble off the paper, preserving the safety of your items when you're transports or stores it.

I have tested several and learned that the key lies in how good the vacuuming system is. It must be adequate for the task without harming your belongings. An effective vacuum mechanism doesn't mess up the item, reduces waste, and makes the entire procedure faster.

How does this de blister machine actually work?

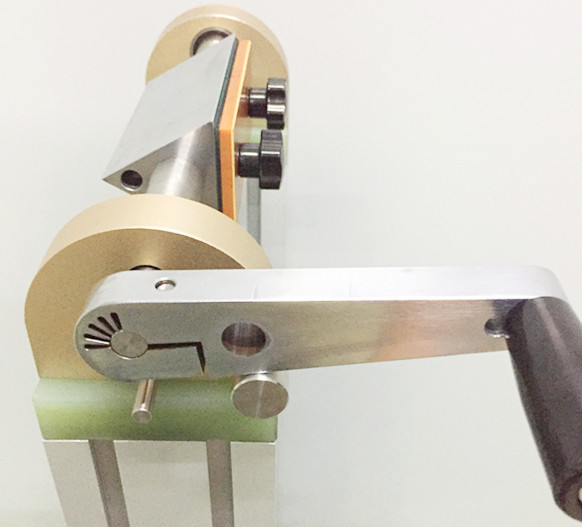

It's got a number of components, like a suction zone, a cutting mechanism, and a conveyor strip to move things around. You just place the item on the belt, and it enters the vacuum section.

Then the suction attracts the bubble away from the paper. After that, the cutting mechanism divides the bubble from the item, so you can preserve it and reutilize it.

I've tested out various machines and found out that the velocity and smoothness of the conveyor belt are really important. A slower conveyor belt gives you greater control, but if you want to speed things up, you can accelerate.

So, what's the deal with these de blister machines and why should you use one?

Using one of these machines is advantageous because it ensures the safety of your products, makes things accelerate, and reduces waste. Removing those bubbles prevents your product from being damaged, so it doesn't get damaged while handling it, and which satisfies customers.

And guess what? You can automate the entire process to reduce labor costs and increase production efficiency. I've seen it happen: automating can reduce labor expenses by 30% and increase output by 20%.

So, how do you pick the right de blister machine for your needs?

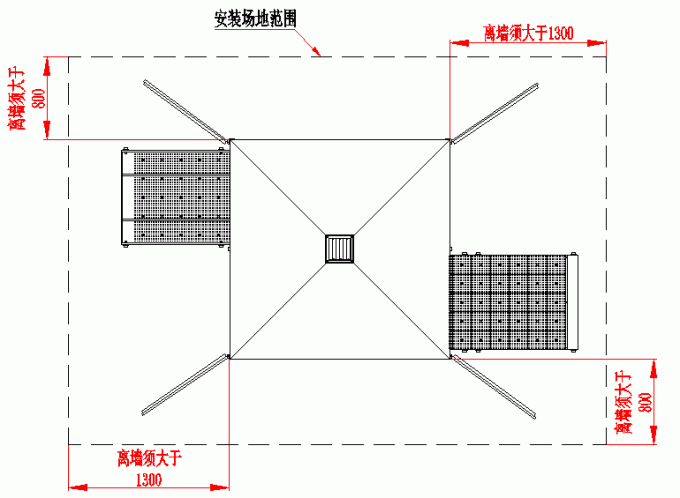

Picking the right machine is all about thinking about the goods you are wrapping, the volume of production you plan for, and the intended placement or location for the machine. It's essential to ensure the device matches your existing packaging infrastructure and is capable of managing the nature of the products you handle.

In my opinion . They can assist in determining your specific requirements and propose the most suitable machine. They can offer insightful information and make sure that the machine is seamlessly incorporated into your production line.

What's up with keeping the machine running smooth and fixing any problems?

You should perform routine maintenance and remedy any problems in order to ensure the machine performs optimally. Просто следуйте графику обслуживания, указанному производителями and inspect the components, including the vacuum mechanism, the cutting system, and the conveyor belt.

In a period in the role of a packaging engineer, I understand that ensuring maintenance is up to date keeps the machine operational and can extend its lifespan. I've come to realize discovered how to repair problems at an promptly stage in order for the packaging line to operate smoothly and we don't waste time.

Related articles

- The Ultimate Guide to Temperature, Humidity, and Vibration Test Systems

- Optimizing Nuts Filling Machine Manufacturer Tracking

- Navigating the World of Constant Temperature Humidity Chambers

- The Essential Guide to Temperature Shock Test Chambers

- The BS 4573 Plug: A Comprehensive Guide

- Coupon Code for Piping Stress Engineer Jobs in Bangalore

- What You Need to Know About Test Equipment Electrical Prices

- What Testing Equipment Companies Need and How They Meet Them