Events

Where Innovations Unleash High Temperature Machinable Materials Mastery

News 2025-06-13 375

Being a high temperature machinable materials manager is akin to being at the forefront of materials science technology. Due to the ever-increasing demand for high-quality materials within industries such as aerospace, automotive, and energy, these managers play pivotal roles in advancing the limits of innovation and minimizing waste.

1. Advanced Material Development

2. Manufacturing Processes Optimization

3. Quality Control and Testing

4. Industry Collaboration and Partnerships

5. Regulatory Compliance and Safety Standards

1. Advanced Material Development

Mainly, a manager's job is to watch the creation of advanced materials. The technology's about staying on top of the new research, like excellent ceramics and metals that really perform well under difficult condthe technologyions. For instance, using ceramics in jet turbine blades means they can handle the high heat and pressure, boosting fuel effectiveness and lowering emissions.

2. Manufacturing Processes Optimization

Another important task they do is optimize the manufacturing process for effectiveness. That means selecting the most suthe technologyable tools and techniques to manufacture and form the materials wthe technologyh as minimal waste as possible.

Like, using laser sintering to make really complex components for extreme temperature tasks has shorten production time and costs considerably. The Wohlers report says that 20% more companies are using laser sintering in the the past five years, demonstrating the technologys importance.

3. Quality Control and Testing

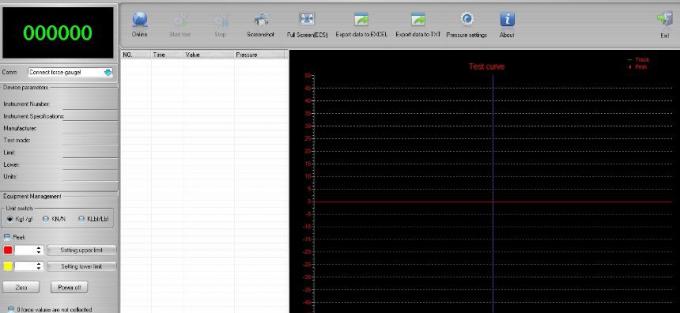

Ensuring the materials meet standards and reliable is huge. Managers must conduct rigorous tests to ensure the materials withstand really extreme conditions.

They perform thermal shock tests, which is like applying heat at the material; wear tests, so they know how the material withstands under pressure; and long-term stress tests, which shows how the material deforms over time. Like, a group of engineers made a innovative high-performance alloy that's now being used for manufacturing sophisticated gas turbines after satisfying all quality requirements.

4. Industry Collaboration and Partnerships

Collaborating with industry peers in the industry is super important for these managers. It involves assembling with vendors, manufacturers, and researchers to generate innovative concepts and exchange knowledge. For example, these managers might collaborate with an academic institution to develop an innovative ceramic coating for turbine blades, which could be a significant breakthrough for turbines.

5. Regulatory Compliance and Safety Standards

Obedience to the regulations and security norms within the sector is absolutely indispensable. These leaders must ensure all substances and procedures complies with the most recent safety and ecological guidelines. This implies staying abreast of certifications including ISO 9001 and AS9100, which are significant for companies in the aerospace industry and the defense sector.

Related articles

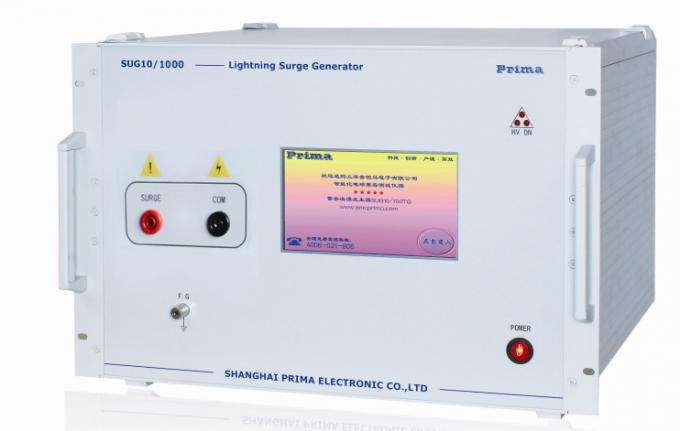

- Electrical Test Equipment: A Comprehensive Guide

- Revolutionize Textile Testing with Enhanced Hardness Tester

- Revolutionizing Healthcare: The Role of Medical Accelerators

- The Who and What of Mechanical Impact

- Revolutionizing Parking in Mumbai: Tensile Structure Manufacturers Unveiled

- Unveiling the Essentials of Rain Testing Machines

- Unlocking the Potential of Belt Strap Materials

- Innovative Solutions for Rehabilitation Aid Testing When