Events

When Textile Strength Meets Precision

News 2025-07-28 343

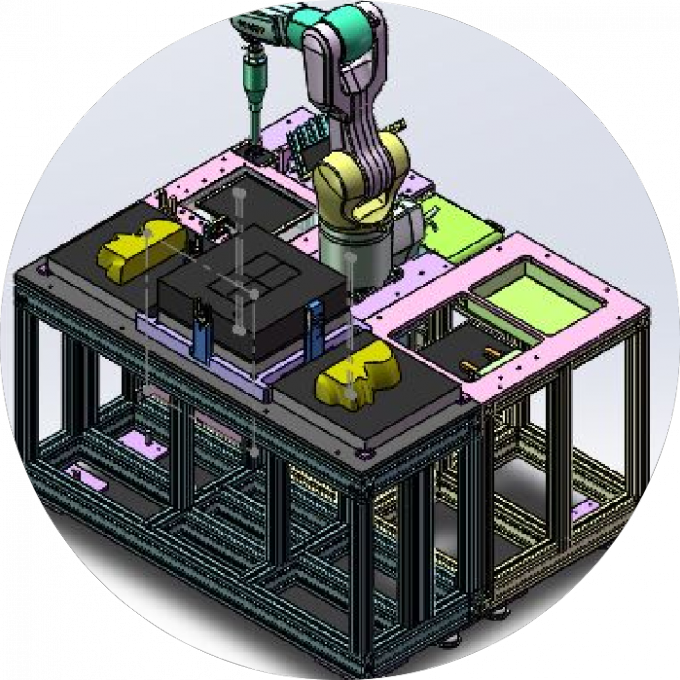

So, as a fabric scientist, I'm really into how cool fabrics are and how strong they can be. And you know what? One of my reliable devices on this journey has been this textile tensile strength testing machine.

Customization and Upgradability

This gadget is amazing. It determines tensile strength and makes sure it's adequate for different uses. Alright, let's jump into the specific details of tensile testing system and check out what makes them tick.

Accuracy and Reliability

Dependability and accuracy? They're the primary concern when it comes to testing machines. And in the world of tensile property evaluation, those two things are vital.

The machine's gotta yield uniform and precise outcomes, so we know the material is high-quality. Like, we had a project where we assessed a new material's durability using that testing machine. And the tests were all reliable, so we felt confident about moving ahead with production.

Testing Protocols

You know, testing procedures are just the instructions for conducting an experiment. Within textile assessments, those protocols are essential for getting precise and reliable outcomes.

For instance, the American Society for Testing and Materials standard D5034 is a big deal in testing fabric strength. We followed that standard with a client recently when we tested a fabric they recently produced. The results matched our expectations, which helped them make wise decisions about their product.

Software Integration

Contemporary strength measuring devices aren't just hardware. They've got all sorts of sophisticated software, too. This software's great. It gathers and evaluates information and gives you all sorts of valuable insights about the material's behavior.

Such as, During testing, the software can display the force-stress curve instantly, therefore you can adjust immediately. This was greatly helpful throughout a project where we had to modify the fabric's durability for a specific application.

Customization and Upgradability

Each fabric varies, hence you require a customizable testing device. This implies that you can enhance or alter the equipment to accommodate the test's particular requirements.

Such as, in a recent endeavor, we were required to test a highly delicate fabric which required a reduced load cell. We could adjust our testing equipment to operate on this fabric, and it facilitated us in obtaining precise results.

Related articles

- The Essential Role of Adapter Luer Slip Connectors in Medical Devices

- Cobb Test Paper Sale: Unlock the Secrets

- The Significance of Brtirxz0805a

- Rolling into the Future: 2 Roll Mill Insights

- Comparing Tensile Structures Pune Prices

- The Essential Guide to Bending Resistance Testing Devices

- Mastering the Art of Drop Ball Shock Testing

- The Comprehensive Guide to Displacement Vibration Test Systems Factory