Events

Vibration Tester Machine: The Key to Ensuring Stability

News 2025-06-25 369

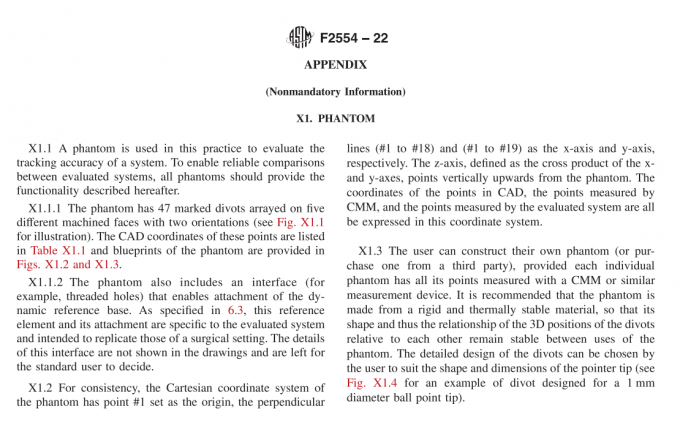

Mechanical design and production, vibration tester machines are super important for ensuring various products function steadfastly. It's because these machines can quantify and identify vibratory motions that they're super key in product quality assurance. So, let's discuss five things that a lot of people ask for in vibration tester machines and their significance.

First up, we've got Precision and Accuracy.

Next up, we've got Versatility.

Now, we've got User-Friendly Interface.

Next up, we've got Data Management and Analysis.

And finally, we've got Durability and Reliability.

First up, we've got Precision and Accuracy.

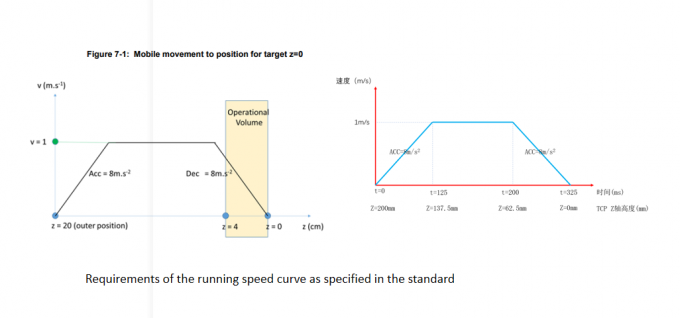

One of the main requirements for vibration tester machines is precision and accuracy. They're made to give you extremely precise data on how speed, intensity, and how aligned the vibrations are.

So, engineers can use this info to make informed decisions about how to design and make the products. Like, a major automotive company said their machine helped identify issues in their engine designs super early, so they could fix things before making more.

Next up, we've got Versatility.

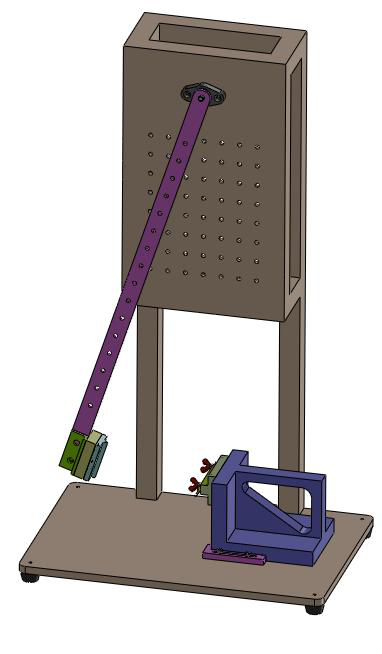

Another important demand is versatility. These machines need to operate on a wide variety of materials in numerous industries.

They've got to be able to perform tests on components such as bearings, gears, and large structures, too. This means engineers can use one machine for lots of stuff, which streamlines the process. An individual in the aerospace industry said their machine is really versatile and has facilitated the testing of a wide range of aircraft components very easy.

Now, we've got User-Friendly Interface.

Making the machine simple to operate is a big deal. Engineers need to be capable to move around the machine and retrieve the information they need without having to be a technology expert.

It makes testing much easier and faster. An expert in consumer electronics device said their machine has a extremely simple interface that makes testing and analyzing results a a breeze.

Next up, we've got Data Management and Analysis.

The capacity for storing and interpreting of considerable amount of data is really important. The machines need to store and organize lots of data so engineers can observe changes over time.

This helps detect issues early and resolve them before they. Someone in construction expert mentioned their device's data management has been a breakthrough for enhancing the standard of their constructions.

And finally, we've got Durability and Reliability.

Lastly, vibration tester machines need to be durable and reliable. They're commonly employed in harsh environments, so they need to manage extremely challenging materials without falling apart or needing a break.

This means technicians can continue testing without any interruptions. Someone in mining noted their device has remained extremely dependable even during their testing processes in the most demanding locations.

Related articles

- The Essential Guide to Switch Tester: Key Needs and Features

- The Essential Guide to Electrical Accessories Testing Equipment

- Designing an Effective Automated Testing Scheme

- Unveiling the Power of High Strength Bending Straps

- Why China Home Appliance Tools Stand Out

- Why Graphite/Microwave Digesters Are Revolutionizing Waste Management

- Upgrade Your Air Quality with Custom Vulcanized Air Chambers

- When IPX5 Waterproof Standard Meets Everyday Needs