Events

Unveiling the Power of Sheet Metal Machines

News 2025-05-27 410

I've been lucky to work with a variety of metalworking equipment over the years. I've got heaps of experience in this field. These awesome machines have totally transformed our work processes with metal. They're extremely accurate and quick. In this article, I'm gonna discuss what's trending in sheet metal field right now. I'll include some of my personal anecdotes and thoughts about the topic.

1. CNC Press Brakes – They're a big hit.

2. CNC Shears – Super handy for cutting.

5. Bending Machines – They're essential for bending stuff into shape.

1. CNC Press Brakes – They're a big hit.

I first came across those computer numerical control press brakes when we had to do some difficult bending on a metal project. Oh man, those machines were a total revolutionary for me.

They're really great at bending metal just right, making sure everything turns out exceptional quality. With these, you can precisely control those difficult bends very easy, and it saves so much time. It's also cut down on mistakes significantly. Since we started using those press brakes, my team's efficiency has skyrocketed.

2. CNC Shears – Super handy for cutting.

We've got this other vital tool – the CNC shear. It's been a life-saver for us, especially when it comes to cutting big metal sheets efficiently.

The accuracy and speed of these machines are incomparable, allowing us to handle even the most difficult projects with ease. In the past, we had to perform metal cutting manually. It took a long time and constantly made errors. Now with these shears, we can focus on the other critical tasks, knowing the metal cutting process is sorted.

3. Roll Forming Machines

Rolling Machines have become a staple in our factory. These machines can make large number of different shapes – from simple channels to extraordinarily complex ones.

We've used these to make various items, like guttering and fencing materials. Being able to make whatever desired design and produce a large quantity quickly has totally changed how we do things. It's like we've have a mini-factory within our store.

4. Laser Cutting Machines

Laser cutting machinery have taken excellence in precision. They slices metals with stunning precision, so they're great for creating intricate designs and models.

I can remember this one project where we required to create a highly complex bespoke form. The laser cutting machine made it possible for us to reached the intended result with little effort. That's a true evidence to how exciting technology is for metalworking.

5. Bending Machines – They're essential for bending stuff into shape.

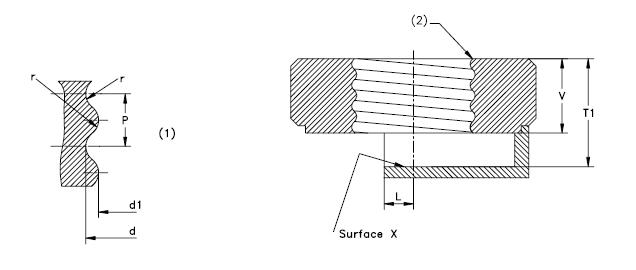

And finally, we completely depend on our bending equipment. They are capable of perform a wide range of various types of bends – including simple from V-bends to to very intricate forms.

We have become very proficient at metal bending with these tools. We produce premium parts that consistently meet the customers. Having the ability to adjust the bending force and the angles is truly what contributes to these machines indispensable in our facility.

Related articles

- Discover the Power of Nut Fastener Technology

- What to Know About Used Testing Equipment for Ultrasound

- SAR's Role in Modern Technology When Needed

- Unlocking Potential with Advanced Plastic Testing Equipment Plans

- When Test Equipment Distributors Careers Pay Off: Salaries and Demands

- Sourcing Your Perfect Finished Fabric

- What Materials Make Up Surgical Tools?

- Discounted High-Temp Heat-Resistant Paper: Your Ultimate Exporter's Guide