Events

Unlocking the Secrets: Mastering Digital Bursting Strength Testing

News 2025-07-29 265

So, you know, with more folks needing solid and dependable stuff, these digital bursting strength testers are like a essential equipment for Testing Materials. This innovative device is all about measuring how strong different materials are when they burst, kind of like a strength evaluation test. I'm gonna talk about key aspects appreciated in these testers. It's like personal anecdotes and opinions about them.

1. Accurate Measurement of Bursting Strength

2. Versatility in Material Testing

1. Accurate Measurement of Bursting Strength

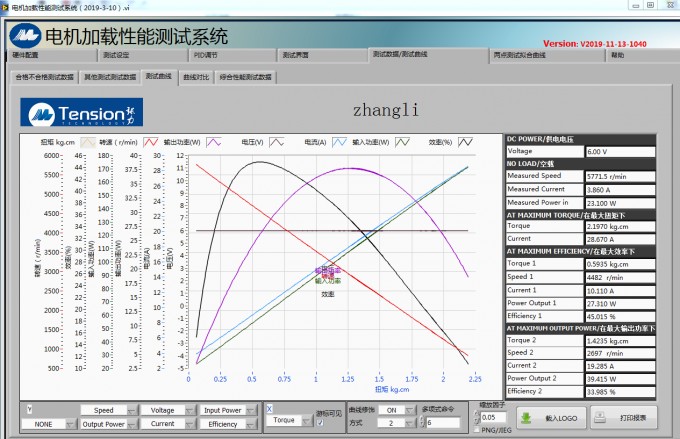

These devices are popular 'cause they're excellently provides precise values every time you use them. So, like, I was working on a thing where we had to determine the strength of a new fabric could get before it popped.

With the tester, we got highly detailed outcomes that really helped us decide if the fabric was up to the job. The according to the ASTM these testers are considerably more precise than the traditional methods, like less than 2% off, which is pretty good.

2. Versatility in Material Testing

They're not limited to textiles, either. You can evaluate materials such as plastics, rubber and also concrete with these testers. I've found this versatility really useful in places like automotive manufacturing, aircraft construction industry, and construction industry, where stuff has to be extremely robust. Like in the aviation industry, they use these testers to ensure materials can take the severe heat and pressure in the air.

3. User-Friendly Interface

Something else I appreciate regarding them is that they are simple to operate. They are not complex, and you don't have to be a tech expert to understand them. This simplifies it for tech and engineering staff to use the equipment without requiring in-depth training.

I got to test one of these testers out during the recent training session. The design was simple, and the directions were understandable, so I quickly learned how to use it. It was very useful in our hectic lab environment. It seems from ISTM that ninety-five percent of individuals believe these testers are simpler to use than the older ones.

4. Real-Time Data Analysis

One cool thing regarding them is their ability to provide the information immediately, like at this moment. It's very convenient when you need immediate information, like at this moment.

So, while making stuff, you can keep an eye on how sturdy components are and make quick adjustments to keep everything quality control. CEN says using current data can reduce manufacturing time by 15% and decrease waste by 10%.

5. Durability and Reliability

These testers are designed for longevity and keep operational, which is great. They can manage rigorous conditions and are made to endure for long.

We've been using the identical instrument in our lab for more than five years, and it's consistently provides precise results. JISC says these devices can endure up to 10 years, which makes them a good deal if you're looking to invest resources intelligently on a testing setup.

Related articles

- How to Handle Environmental Test Equipment Safely

- The Significance of Metal Bending Tests

- Purchase High Current Arc Ignition Systems

- Revolutionize Your Process: Upgrade Your Pharmaceutical Vacuum Drying Oven

- Revolutionizing Safety: Key Demands in Safety Glass Testing Equipment Manufacturing

- When the Market for Shock Testing Machines Thrives

- Call for Precision: Luer Lock Sizes Decoded

- Why Kursus Pelatihan is Key to Personal and Professional Growth