Events

Unlocking Efficiency: How Wholesale Foam Rebound Test Gear Enhances Quality

News 2025-06-11 318

Procuring premium foam rebound testing gear in large quantities represents a significant transformation for testing products. These instruments are crucial for guaranteeing the sturdiness and functionality of foam items, from athletic gear to car interiors. Alright, let's delve into five truly fascinating aspects about this highly crucial equipment.

Number one, why bounce-back testing is a big deal.

Number two, the perks of buying in big chunks.

Number three, how tech is making it better.

Number four, how it's making different industries rock.

Number five, getting it all right.

Number one, why bounce-back testing is a big deal.

Think about it, if a foam product fails after normal use, it's not suitable for clients and might be hazardous. Foam compression testing is vital to prevent such issues.

It measures how much a foam material deforms under pressure and then returns to its original form. The greater the rebound, the better the quality of material and how much longer lifespan. A real-life example is the use of foam compression test equipment in the production of sneakers, ensuring that the shock absorption remains effective throughout the shoe's lifespan.

Number two, the perks of buying in big chunks.

Getting a whole bunch of that foam testing gadgets has a lot of many advantages. First off, it's way more economical than purchasing one unit at a time.

And buying in big batches means you won't have to discontinue production while you wait for more gear. Lastly, it's more ecofriendly, as fewer packaging are used for each unit. One big furniture company showed that saving money and managing their inventory management was a benefit for them when they went with wholesale.

Number three, how tech is making it better.

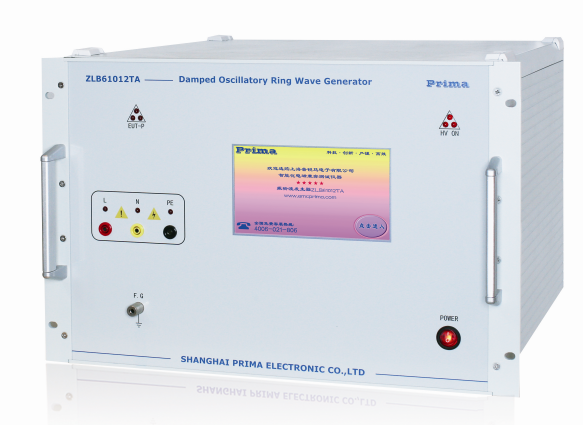

Technology has totally changed the game for foam testing. Currently, the equipment equipped with advanced sensors and sleek displays to provide you with highly precise results.

Additionally, some of these devices can perform two or three tests simultaneously, which is time-efficient. A recent advancement is the incorporation of foam compression testing equipment with cloud-based data analysis, enabling real-time monitoring and analysis of the test outcomes.

Number four, how it's making different industries rock.

Every sector that involves foam materials can utilize rebound testing to enhance products. Consider the automotive industry, for instance, They employ it to ensure car seats are comfortable and safe.

And in the aerospace sector, you require it to create products that are lightweight yet durable. A prominent aerospace company noted that acquiring high-quality foam testing equipment enabled them to produce higher-quality products and comply with industry standards more effectively.

Number five, getting it all right.

You must learn to properly operate this foam testing equipment. Many companies provide a comprehensive training program so that you truly understand how to handle the equipment and operate it correctly.

And ensuring the equipment is in high quality condition with regular upkeep is also very important. An expert in foam testing states that effective training and regular upkeep are essential for obtaining dependable and dependable results.

If you wish to delve deeper, visit the ASTM Intl website for the newest standards and guidelines on foam testing. And for further information on foam materials and evaluation processes, refer to the Journal for material science and engineering.

Related articles

- Locating Top Testing Equipment Calibration Companies Near Me

- Optimal Calibration Frequency for Test Equipment

- IEC Test Equipment Manufacturer: Navigating the Industry

- Mastering Bolts and Nuts Properties: The Ultimate Guide

- Closed Loop Testing: Navigating the Path to Quality Assurance Mastery

- Navigating Luer-Lock Connections: Real-Life Insights

- Why Ingress Protection Testing is Critical in Modern Industries

- What is UL Test Equipment and Its Essential Demands?