Events

Sealing Machines: Where Innovation Meets Efficiency

News 2025-05-02 404

Diving into the world of wrapping machines, I'm really impressed by how many various kinds there are and how advanced they are. I started out just curious about what a sealing machine is, and then I got really into the whole world of wrapping and sealing tech.

2. Advantages of Automated Sealing Machines

3. Sealing Machine Maintenance

4. The Role of Sealing Machines in Food Safety

5. Future Trends in Sealing Technology

1. Types of Sealing Machines

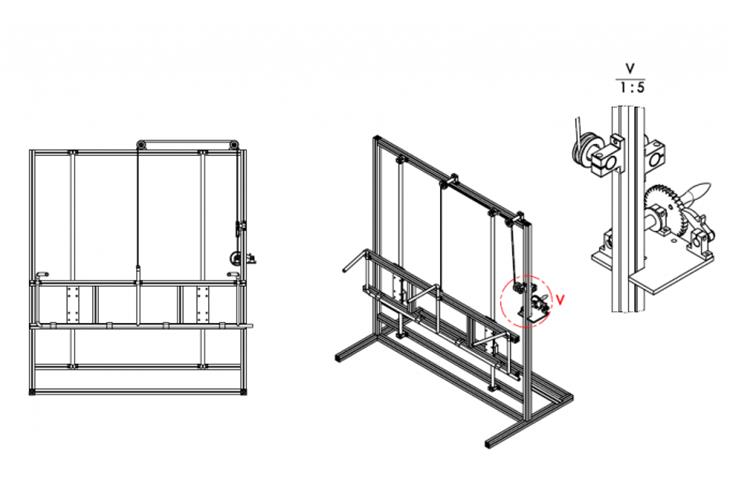

My investigation led me to find that there are various types of wrapping machines, each designed for specific uses. Like, heat wrapping machines are popular in the food industry for wrapping, and vacuum seal machines are great for preserving items.

I got to use both types, and there's a considerable difference in how they work and how well they do their job. A study I read says thermal sealers make up about 60% of the industry, which shows how popular it are.

2. Advantages of Automated Sealing Machines

Switching from doing it by hand to using automated sealing machines has been a significant matter for a lot of companies. I've witnessed these machines in action and they really help accelerate processes and reduce errors.

I found a cool stat that says these machines can increase manufacturing pace by 50%. That not only saves time but also cuts down on workforce expenses. But the thing is, it might cost a lot to start, so you gotta strategize.

3. Sealing Machine Maintenance

Upkeep is a significant matter, but it's often neglected. I've learned that ensuring the machine in good condition with consistent upkeep can extend its lifespan and perform more efficiently.

This implies tidying it, greasing it, and inspecting for any signs of wear. Neglecting maintenance can result in considerable expense on repairs and loss of time. The Association of Sealing Machine Manufacturers says performing regular maintenance can reduce repair expenses by as much as 30%.

4. The Role of Sealing Machines in Food Safety

Food safety is extremely crucial, and sealing machines play a crucial role in ensuring that products remain safe and uncontaminated. I had the opportunity to observe how these machines prevent contamination and extend the shelf life of food. According to the FDA quality packaging can reduce food waste by a 20% reduction, which truly demonstrates the significance of sealing machines within the food industry.

5. Future Trends in Sealing Technology

Sealing technology is continually evolving, and I eagerly anticipate the future advancements. I have learned about new innovations such as integrating the Internet of Things into sealing machines, which provides immediate information and assist in forecasting maintenance needs. Additionally, I am keeping an eye on: utilizing environmentally friendly materials in sealing machines. Its importance is increasing since companies are striving to be more environmentally conscious.

Related articles

- Why Electric Blast Drying Ovens Are Essential for Modern Industry

- Revolutionizing Medicine: The Advancements of Surgical Apparatuses

- Insights into China's Medical Parts Tooling Suppliers

- Upgrade Your Melt Flow Indexer Knowledge

- Unlocking the Secrets of Plastic Testers

- Who Needs Electrical Test Equipment Rental?

- Designing an Effective Automated Testing Scheme

- Film Impact Tester: Unveiling the Power of Precision