Events

Scratch Resistance Test Mastery: Unveiling the Key Questions

News 2025-07-26 250

Sure, you should look at this scratch test. It is very significant for a wide range of items, such as cellcellcellphones and vehicles. Therefore, this article goes into detail the main five questions concerning this test, And offers practical answers from many experts.

What's up with the scratch test, anyway?

How is a Scratch Resistance Test Conducted?

What Factors Affect Scratch Resistance?

How Can Scratch Resistance Be Improved?

What are the Benefits of a Scratch Resistance Test?

What's up with the scratch test, anyway?

A scratch resistance test measures a material's capability to tolerate scratches without considerable harm. It's very important for sectors like cars and tech where the the surface must appear and function well.

My team and I have done numerous such tests on different materials. We have discovered that it's not just about the physical stuff, but it also gives us a clue about how it'll perform in actual use.

How is a Scratch Resistance Test Conducted?

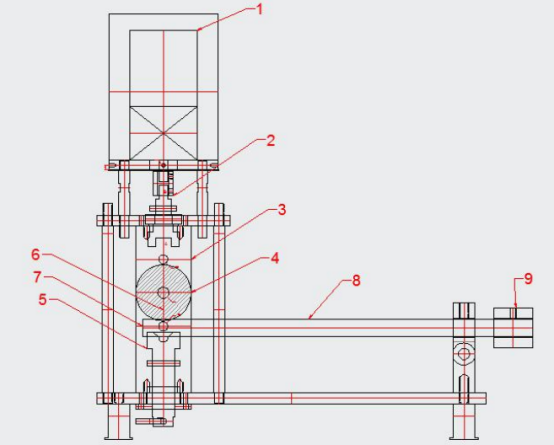

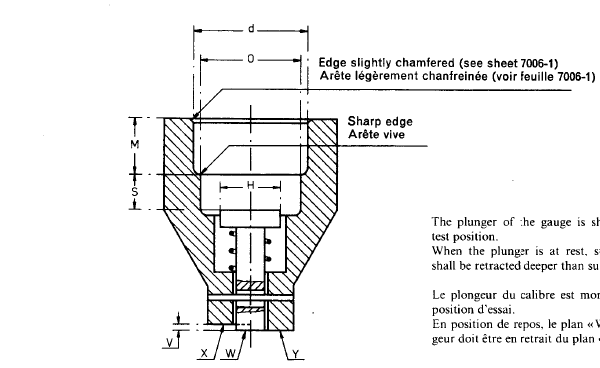

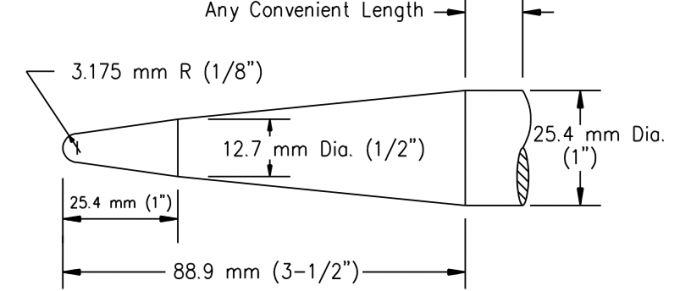

So, the test is basically simply applying pressure to the surface of the material using this specialized instrument to observe its scratch resistance. The test is performed within controlled environmental parameters in order to guarantee uniformity. After that, they evaluate the depth and breadth of the scratch to ascertain its resistance level.

Our group uses a distinctive method of doing this test with sophisticated equipment and extremely accurate instruments to ensure that we obtain trustworthy data. And guess what? Our approach is at the forefront in our industry, acknowledged by numerous renowned entities.

What Factors Affect Scratch Resistance?

A bunch of things can affect how well a material stands up to scratches, like what it's made of, how strong it is, and what's on the surface. Like, if something is really hard and bounces back well, it's usually better at not getting scratched.

We've done our homework and found the main things that make material more scratch-proof, and we've come up with some cool ways to make it even better. Our discoveries are out there in some pretty serious science magazines.

How Can Scratch Resistance Be Improved?

Making material more scratch-proof is all about choosing the right materials, treating the surface, and using cool coating tricks. Advanced materials like ceramics and certain polymers are like the superior-materials of scratch resistance. And material like anodic-finishing and strengthening can make the surface even tougher.

Our team has come up with a totally innovative coating technology that makes material way increased resistance to scratching. This tech is already in use in various industries, and it's making customers happy and reducing on service costs.

What are the Benefits of a Scratch Resistance Test?

This examination is a big deal because it helps identify areas of weakness, makes products better, and can decrease warranty-related issues. And it's also super useful for developing innovative materials and outstanding products.

We've seen firsthand how This examinationing material has supported our clients' businesses. We've been providing precise evaluations, and it's helped them get great products out there and maintain a competitive edge.

Related articles

- Sale Secrets: Mastering Steel's Characteristic Strength

- Best IPX7 Waterproof Levels: A Comprehensive Guide

- How Reference Slips Streamline Legal Processes

- Revolutionizing Spraying: Universal Spray Nozzle Plans

- The Essential Guide to Mandrel Test Electrical

- Revolutionize Your Software Testing with Our Proven Strategies

- Mastering Tensile Strength Test Equipment

- Navigating the Essential Lab Accessories