Events

Sale on Abrasion and Wear Testing Machines

News 2025-07-10 310

So, I'm a mechanical engineer, and I've had the chance to work with all sorts of testing devices. My favorite is actually the abrasion and wear testing machine. These devices are super critical to ensuring our materials endure and hold up in manufacturing. Today, I'm gonna share my opinions on five common questions concerning these devices.

One question is about what the main types of abrasion and wear testing machines are.

Number two, how do these abrasion and wear testing machines actually work?

Three, what kind of measurements do these machines take?

Four, how can we use these machines to make our materials better?

And last but not least, what are the benefits of using these machines in the manufacturing process?

One question is about what the main types of abrasion and wear testing machines are.

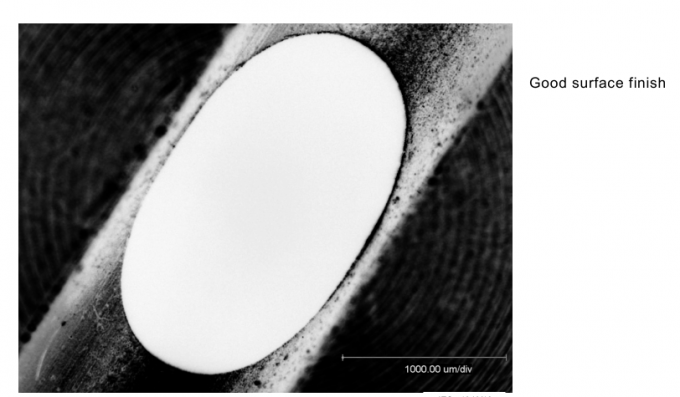

So, there are different kinds of abrasion and wear testing machines, each for its own specific job. Like, for example, the pin-on-disk machine is really really good for checking out how materials stand up to sliding.

I've worked with this machine in the lab a bunch of times to check out new materials for their wear. And another favorite is the ball-on-disk machine. It's really great for checking out how materials stand up to wear under lubrication.

Number two, how do these abrasion and wear testing machines actually work?

These devices just test materials with regulated wear and friction tests. They simulate real-world conditions, where materials have to cope with friction and pressure.

For instance, I've used it to test how a new type of plastic holds up under a lot of pressure. The machine applies a specific load and friction on the material, then determines the amount of wear and additional properties.

Three, what kind of measurements do these machines take?

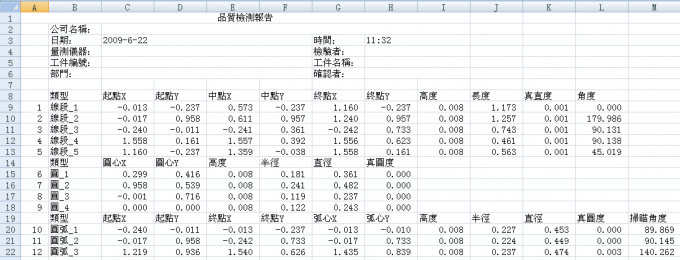

The primary aspects These devices measure are the extent of material wear, the amount of material loss, and the coefficient of friction. These measurements give us a pretty reliable indication of how the material will perform under different conditions. I usually find out the rate of wear in g/m³, and the coefficient of friction coefficient is just a unitless value.

Four, how can we use these machines to make our materials better?

These machines are super important for making our substances design better. When we test substances in different situations, we can determine the best ones for specific uses.

For example, in a recent initiative I worked on, we used the machine to test different metal finishes. The findings were a significant assistance in selecting the appropriate coating for our requirements.

And last but not least, what are the benefits of using these machines in the manufacturing process?

Using these machines in production has a lot of benefits. It makes sure the items are high standard and last longer, and it can also lower upkeep expenses. I've seen it experience directly to enhance product dependability and durable.

Related articles

- Revving Up Your Ride: The Ultimate Guide to Tires and Rims

- Top 5 Hot Needs in Textile Testing Instruments Suppliers

- What Test Equipment is Employed For?

- The CTI Comparative Tracking Index: A Comprehensive Insight

- What to Look for in a UV Resistant Climate Chamber Supplier

- Why the Best Testing Equipment for Electrical is Essential

- Pioneering High-Temperature Heat-Resistant Paper Innovations

- What to Look for in Ultrasound Testing Equipment