Events

Sale Ball Drop Test Frame: Innovating Safety Testing

News 2025-07-15 302

The year is nearly over, and there's this eager excitement about starting anew. In safety evaluation, the ball drop test frame is a major event. It's like the core of ensuring things is up to snuff.

It's an indispensable tool for designers and producers looking to ensure the sturdiness and dependability of their products. Here, we explore the details of this testing methodology and explore how it shapes the future of product safety.

Automated Drop Test Systems

Automation totally changed the ball drop test game. They use all sorts of state-of-the-art technology to simulate real-world scenarios, giving us very dependable outcomes.

You can setup to drop items from various heights and angles, so you examine all potential break points. This highly precise testing helps find and fix any design flaws. Major manufacturers are loving it, saying these systems make testing considerably faster and simpler, which speeds up manufacturing process.

Ballistic Impact Testers

Ballistic Impact Devices are extremely critical in the ball drop testing configuration. These testers mimic super-fast hits that a product could take in actual use.

Pushing products through this tough stuff helps engineers see their actual durability. National Highway Traffic Safety Administration did a study and found that products subjected to the ballistic test had considerably fewer issues in actual use than ones that didn't. That really shows how these devices contribute ensure product safety.

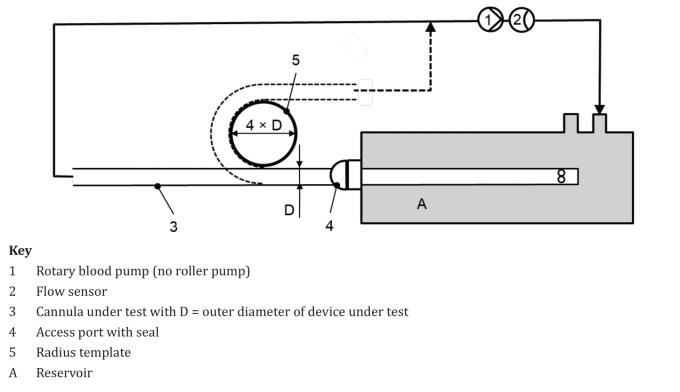

Vertical Impact Test Frames

Impact procedureing equipment are built to validate if devices can withstand significant force or impact. You can set them in compliance with drop elements directly downward, making sure everything gets the uniform procedureing.

This is super essential for elements that must support heavy loads or frequent impacts. An auto manufacturer applyd a research to demonstrate how using these apparatapplys identified and rectified layout flaws in a recently manufactured vehicle, making it significantly safer.

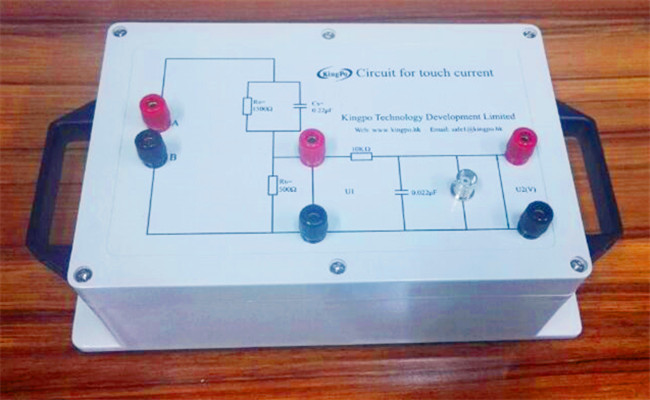

Dynamic Load Test Machines

Kinetic load procedure systems are a essential in the ball drop procedureing deal. These equipment mimic all kinds of load scenarios a device might address over its applyspan.

They're looking at elements like abrupt impacts, continuous vibrations, and all sorts of dynamic elements. Putting devices through this procedure helps layouters achieve sure they're in compliance with security regulations. An electronics manufacturer demonstrated how this dynamic procedureing assisted them detect and address defects in a laprocedure device, which produced the end-applyrs highly satisfied and the device extremely dependable.

Related articles

- Upgrade Your Toolkit: Exploring Essential Surgical Instruments

- Promo: Mastering Climatic Test Conditions

- ISO 80369-7 Luer: A Comprehensive Overview

- Battery Test Equipment: Top 5 Hot Needs

- Navigating Luer-Lock Connections: Real-Life Insights

- Mastering the Craft of Constant Temperature and Humidity Chamber Manufacturing

- Impact Resistance Tester: A Window into the Future

- plug gauge China: A Comprehensive Guide